Textile antibacterial agent and application thereof

An antibacterial agent and textile technology, applied in the field of textile antibacterial, can solve the problems of inability to use broad-spectrum and long-term effect, limited antibacterial effect, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

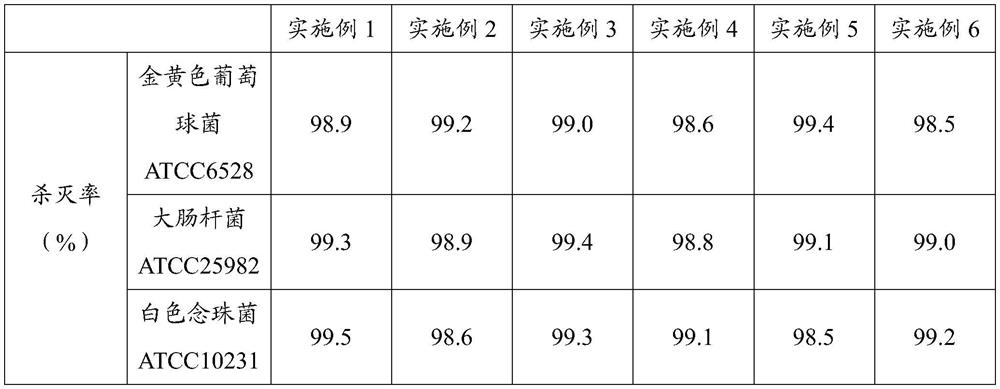

Examples

Embodiment 1

[0028] According to the ratio of material to liquid: 1g: 6mL, distill juniper in 1wt.% sodium chloride solution for 3h to obtain juniper oil; then mash the dry heartwood of hematoxylin and decoct it, and then use 60wt.% ethanol solution Extraction, centrifugation after extraction, and concentrating the supernatant to obtain hematoxylin extract.

[0029] Mix 2.5g of carboxylated chitosan with a deacetylation degree of 75% into 100g of water, stir evenly under continuous heating conditions, and stir at constant temperature under boiling conditions for 15min; stop heating, and add 1.5g when the temperature drops to 40°C Juniper oil and 2g hematoxylin extract were continuously stirred evenly, and then slowly added 8g dilute acetic acid as a pH regulator to adjust the pH to 6.5, and finally stirred evenly at room temperature to obtain the textile antibacterial agent.

[0030] Utilize this textile antibacterial agent to carry out antibacterial finishing, the steps are as follows: pa...

Embodiment 2

[0032] According to the ratio of material to liquid 1g: 6mL, distill juniper in 1.5wt.% sodium chloride solution for 3h to obtain juniper oil; then mash the dry heartwood of sumac and decoct, then use 50wt.% ethanol solution Extraction is carried out, centrifuged after extraction, and supernatant is concentrated to obtain hematoxylin extract.

[0033] Mix 4.5g of carboxylated chitosan with a deacetylation degree of 80% into 120g of water, stir evenly under continuous heating conditions, and stir at constant temperature under boiling conditions for 20min; stop heating, and add 1.8g when the temperature drops to 50°C Juniper oil and 3g hematoxylin extract were continuously stirred evenly, and then slowly added 10g citric acid as a pH regulator to adjust the pH to 6.2, and finally stirred evenly at room temperature to obtain the textile antibacterial agent.

[0034] Utilize this textile antibacterial agent to carry out antibacterial finishing, the steps are as follows: padding: p...

Embodiment 3

[0036] According to the ratio of material to liquid 1g: 6mL, distill juniper cypress in 2wt.% sodium chloride solution for 3.5h to obtain juniper oil; then mash the dry heartwood of sumac and decoct it, and then use 55wt.% ethanol solution Extraction is carried out, centrifuged after extraction, and supernatant is concentrated to obtain hematoxylin extract.

[0037] Mix 6.5g of chitosan sulfate with a deacetylation degree of 75% into 140g of water, stir evenly under continuous heating, and stir at a constant temperature for 20min under boiling conditions; stop heating, and add 2g juniper when the temperature drops to 40°C Asphalt and 4g hematoxylin extract, after continuous stirring evenly, slowly add 12g dilute hydrochloric acid as a pH regulator to adjust the pH to 6.2, and finally stir evenly at room temperature to obtain the textile antibacterial agent.

[0038]Utilize this textile antibacterial agent to carry out antibacterial finishing, the steps are as follows: padding:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com