Milling and blasting combined construction method for water-rich sandy dolomite stratum tunnel

A construction method and a technology of sanding, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as failure to install radial system anchor rods in time, affect the bearing capacity of support structures, and damage to the initial supports that have been installed, and achieve The effect of shortening the unit cycle construction time, improving the excavation efficiency and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

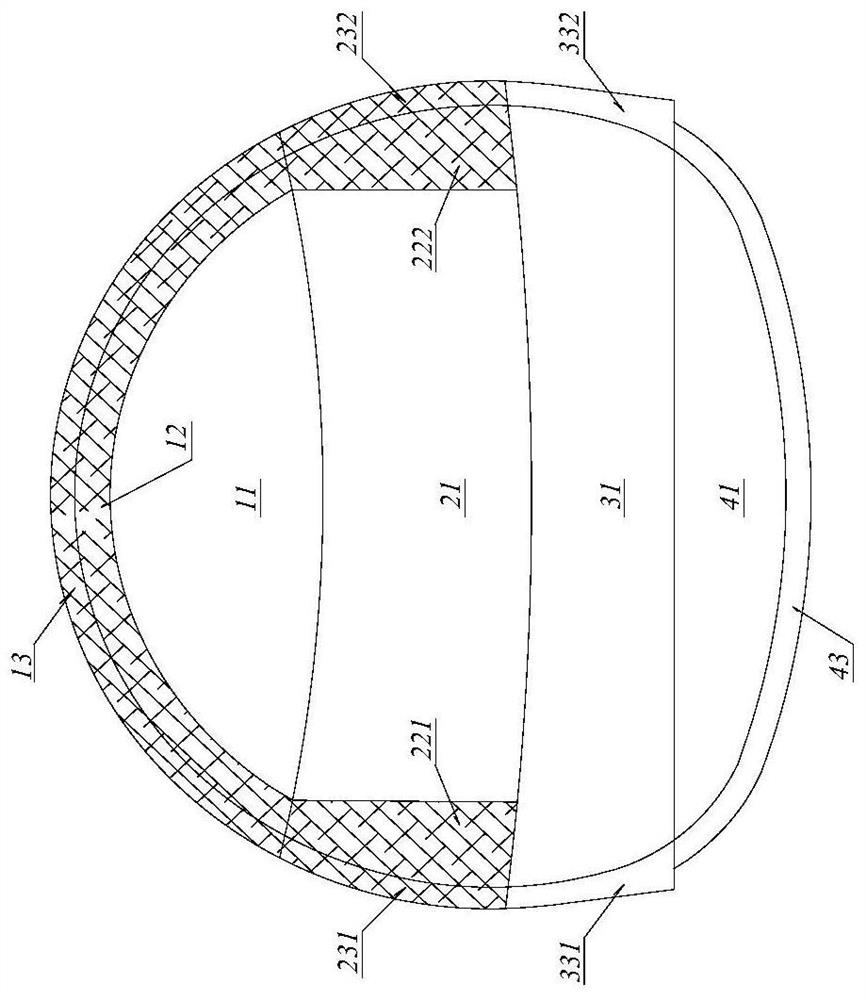

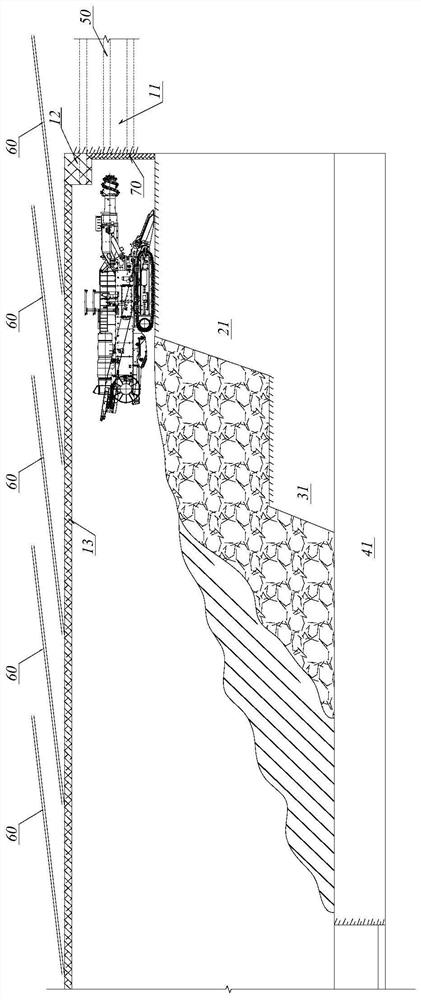

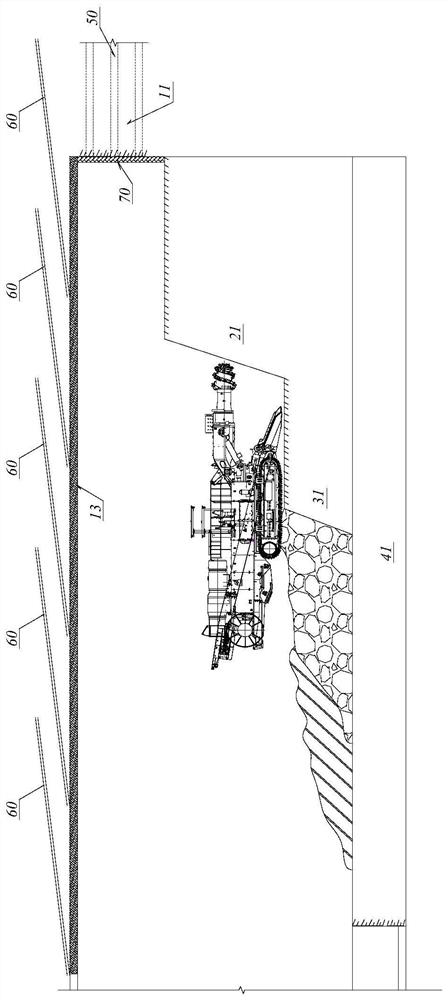

[0029] refer to Figure 1 to Figure 3 , a milling and blasting combined construction method for tunnels in water-rich sandy dolomite formations of the present invention, comprising the following steps:

[0030] ①Preparation work before construction, using advanced drilling and geophysical prospecting means to carry out comprehensive advanced forecasting, to predict changes in rock formations in front of the tunnel face, rock mass integrity, karst development, water inrush location, water volume and water pressure;

[0031] ②Weak blasting excavates the core soil 11 of the upper step, and the excavator on the upper step removes the slag to the position of the middle and lower steps (slag is removed from the lower step at the same time), and then the cantilever roadheader is used to mill and excavate the reserved rock mass 12 of the upper step, to be trimm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com