Submarine degaussing cable and preparation method thereof

A technology for demagnetizing cables and submarines, used in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problem that the properties of steel that are easily magnetized cannot be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

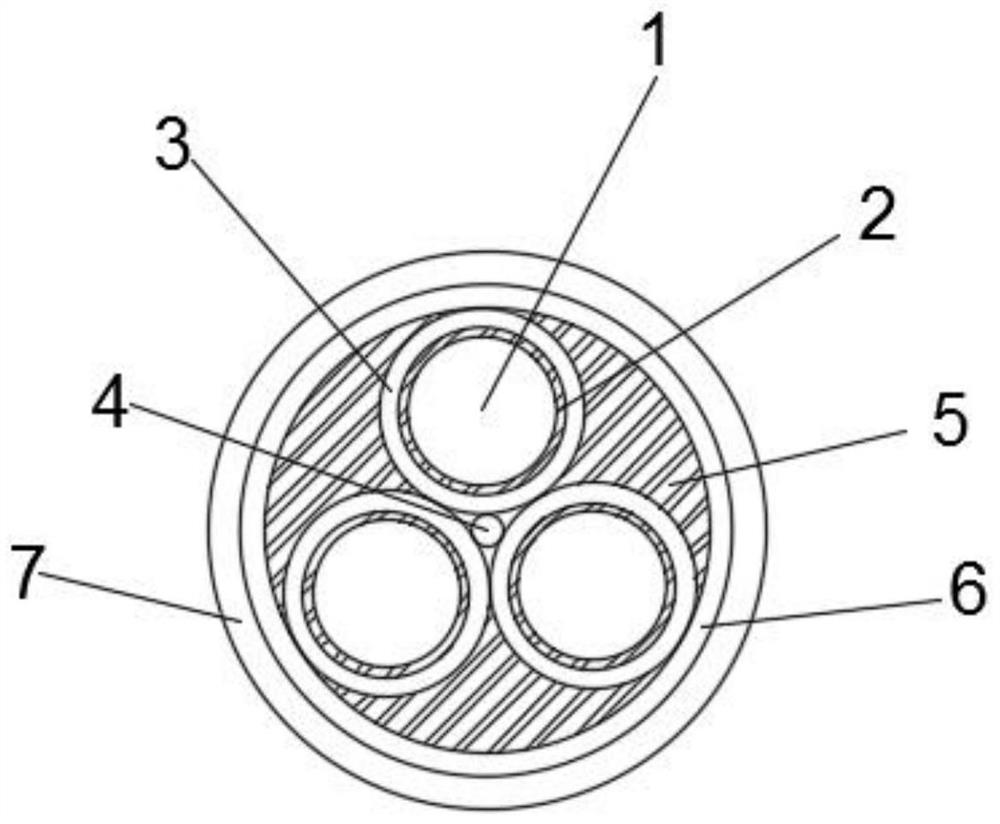

[0037] A submarine degaussing cable, comprising a tinned copper conductor 1, a first sealing layer 2, an insulating layer 3, a filling strip 4, a second sealing layer 5, an inner sheath 6 and an outer sheath 7; the first sealing layer 2 and the second The second sealing layer 5 is sealant;

[0038] Wherein, the sealant is prepared through the following steps:

[0039] Step S11: Add polyether polyol into the reaction kettle, set the temperature at 100°C and vacuum at 0.1 MPa, dehydrate for 1 hour, then lower the temperature to 80°C, add 30% toluene diisocyanate, set the temperature at 85 ℃, react at normal pressure for 50min, then lower the temperature to 80℃, add the remaining 70% toluene diisocyanate, set the temperature at 85℃, react at normal pressure for 3h, then add dioctyl phthalate and mix well After that, prepolymer A is obtained;

[0040] Step S12, add lignin and deionized water into the three-necked flask, adjust the pH of the reaction solution in the three-necked ...

Embodiment 2

[0055] A submarine degaussing cable, comprising a tinned copper conductor 1, a first sealing layer 2, an insulating layer 3, a filling strip 4, a second sealing layer 5, an inner sheath 6 and an outer sheath 7; the first sealing layer 2 and the second The second sealing layer 5 is sealant;

[0056] Wherein, the sealant is prepared through the following steps:

[0057] Step S11: Add polyether polyol into the reaction kettle, set the temperature at 110°C and vacuum at 0.1 MPa, dehydrate for 1 hour, then lower the temperature to 80°C, add 30% toluene diisocyanate, set the temperature at 85 ℃, react at normal pressure for 505min, then lower the temperature to 80℃, add the remaining 70% toluene diisocyanate, set the temperature at 85℃, react at normal pressure for 3h, then add dioctyl phthalate and mix well After that, prepolymer A is obtained;

[0058] Step S12, add lignin and deionized water into the three-necked flask, adjust the pH of the reaction solution in the three-necked...

Embodiment 3

[0073] A submarine degaussing cable, comprising a tinned copper conductor 1, a first sealing layer 2, an insulating layer 3, a filling strip 4, a second sealing layer 5, an inner sheath 6 and an outer sheath 7; the first sealing layer 2 and the second The second sealing layer 5 is sealant;

[0074] Wherein, the sealant is prepared through the following steps:

[0075] Step S11: Add polyether polyol into the reaction kettle, set the temperature at 120°C and vacuum at 0.1 MPa, dehydrate for 1 hour, then lower the temperature to 80°C, add 35% toluene diisocyanate, set the temperature at 85 ℃, react under normal pressure for 60min, then lower the temperature to 80℃, add the remaining 65% toluene diisocyanate, set the temperature at 85℃, react under normal pressure for 3h, then add dioctyl phthalate and mix well After that, prepolymer A is obtained;

[0076] Step S12, add lignin and deionized water into the three-necked flask, adjust the pH value of the reaction solution in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com