Preparation method of high-nickel positive electrode material of composite coating layer

A technology of cathode material and coating layer, which is applied in the field of preparation of high-nickel cathode materials, can solve problems such as limited operation methods, and achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

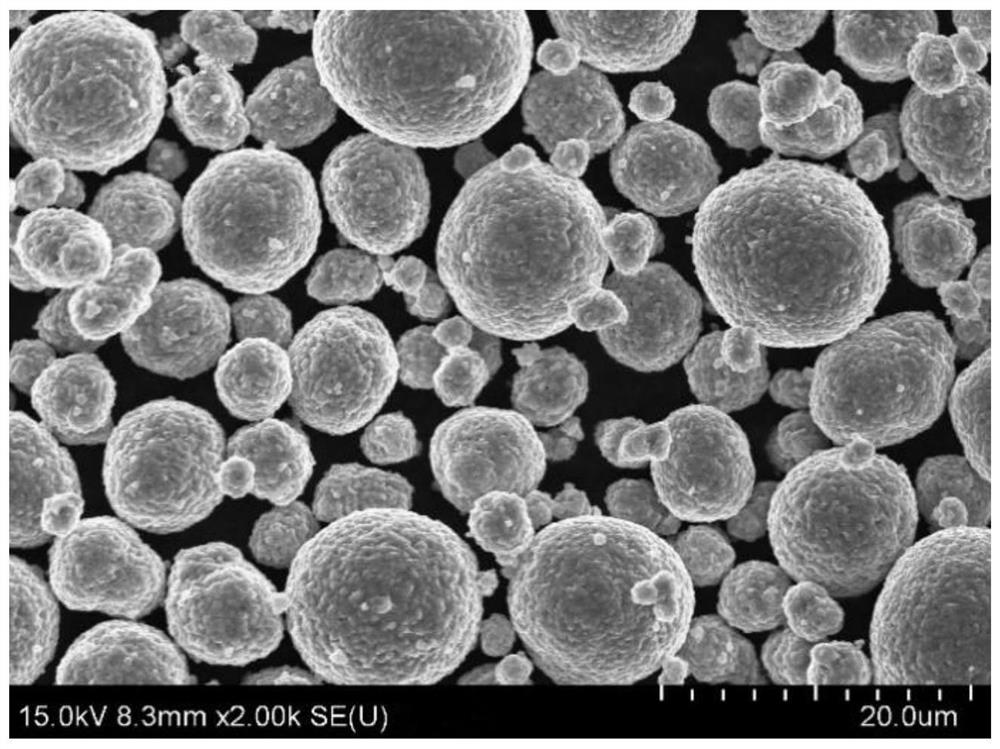

[0030] In a 1L beaker, add 200ml of deionized water, stirring speed 400r / min, 200g high nickel cathode material LiNi 0.80 co 0.10 mn 0.10 o 2 Add it into the beaker, after stirring evenly, slowly add 2.78g of aluminum nitrate, add 1M lithium hydroxide solution during the stirring process, adjust the pH to 9, and continue stirring for 15 minutes. The resulting mixture was filtered, vacuum filtered, rinsed with a little absolute ethanol, and dried. Dry in a vacuum drying oven at 120°C for 4 hours to obtain dried materials, then ball mill and stir with 2.29g of nano-boric acid, sieve, place in a sagger, and react in a preheated box furnace at 320°C for 6 hours under an oxygen atmosphere . After cooling slowly, a positive electrode material with a uniform coating can be obtained after sieving, as shown in the SEM image figure 1 shown.

Embodiment 2

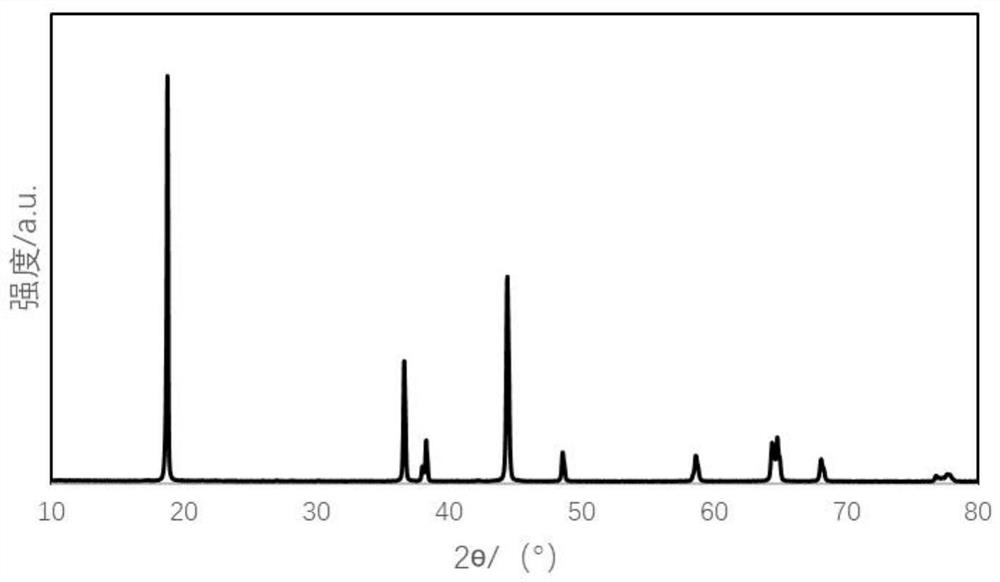

[0032] In a 1L beaker, add 240ml deionized water, stirring speed 300r / min, 200g high nickel cathode material LiNi 0.80 co 0.10 mn 0.10 o 2 Add it into the beaker, after stirring evenly, slowly add 4.17g of aluminum nitrate, add 2M lithium hydroxide solution during the stirring process, adjust the pH to 10, and continue stirring for 20 minutes. The resulting mixture was filtered, vacuum filtered, rinsed with a little absolute ethanol, and dried. Dry in a vacuum drying oven at 120°C for 3 hours to obtain dried materials, then ball mill and stir with 1.15g of nano-boric acid, sieve, place in a sagger, and react in a preheated box furnace at 300°C for 8 hours in an oxygen atmosphere . Cool slowly, and after sieving, a positive electrode material with a uniform coating can be obtained, as shown in the XRD diagram figure 2 shown.

Embodiment 3

[0034] In a 1L beaker, add 160ml of deionized water, stirring speed 500r / min, 200g high nickel cathode material LiNi0.83 co 0.12 mn 0.05 o 2 Add it into the beaker, after stirring evenly, slowly add 4.17g of aluminum nitrate, add 1.5M lithium hydroxide solution during the stirring process, adjust the pH to 9, and continue stirring for 20 minutes. The resulting mixture was filtered, vacuum filtered, rinsed with a little absolute ethanol, and dried. Dry in a vacuum drying oven at 120°C for 5 hours to obtain dry materials, then ball mill and stir with 0.46g of ammonium metavanadate, sieve, place in a sagger, and place in a preheated box furnace under an oxygen atmosphere at 350°C Reaction 6h. After cooling slowly, a cathode material with a uniform coating layer can be obtained after sieving.

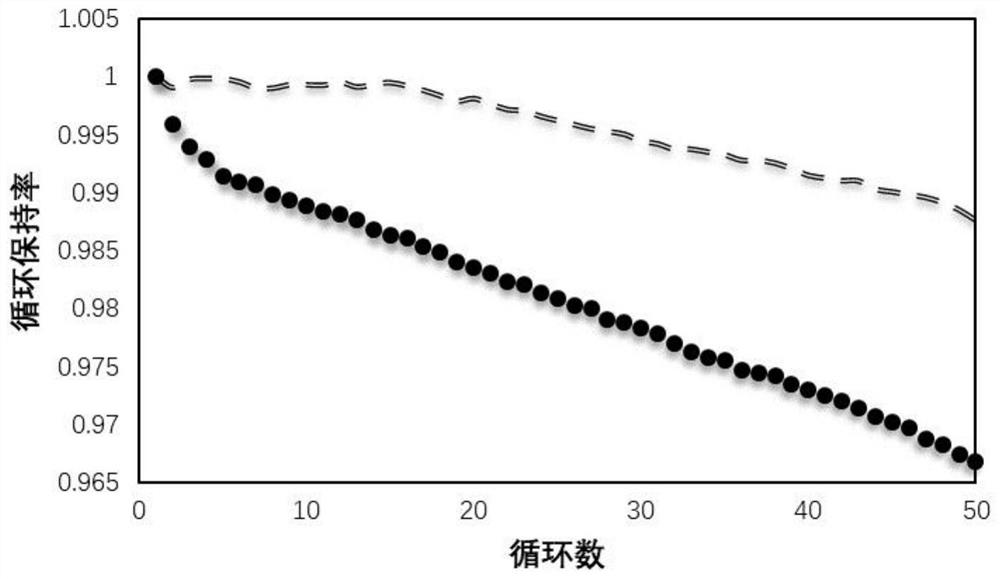

[0035] The high-nickel positive electrode material with coating layer prepared above is cycled under the charge-discharge condition of 1C / 1C, by image 3 It can be seen from the cycle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com