Solid electrolyte membrane, preparation method and battery

A solid electrolyte membrane and battery technology, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve problems affecting the creep of PEO chains and reduce the lithium ion transmission performance of electrolyte membranes, so as to improve oxidation resistance, Effect of improving battery cycle performance and improving battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

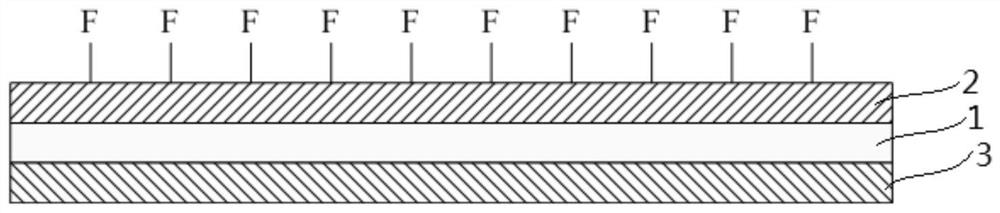

[0033]Dissolve PEO (MW=400000) in DMF / acetonitrile (mass ratio 1:2) to form a 20wt% glue solution, then add lithium salt (LiTFSI) and lithium ion conductor (LLZTO) Membrane 1 (eg figure 1 Shown) on the A side, dried to a PEO coating with a thickness of 12 μm, and set aside. Wherein PEO:LiTFSI:LLZTO=5:2:3 (mass ratio).

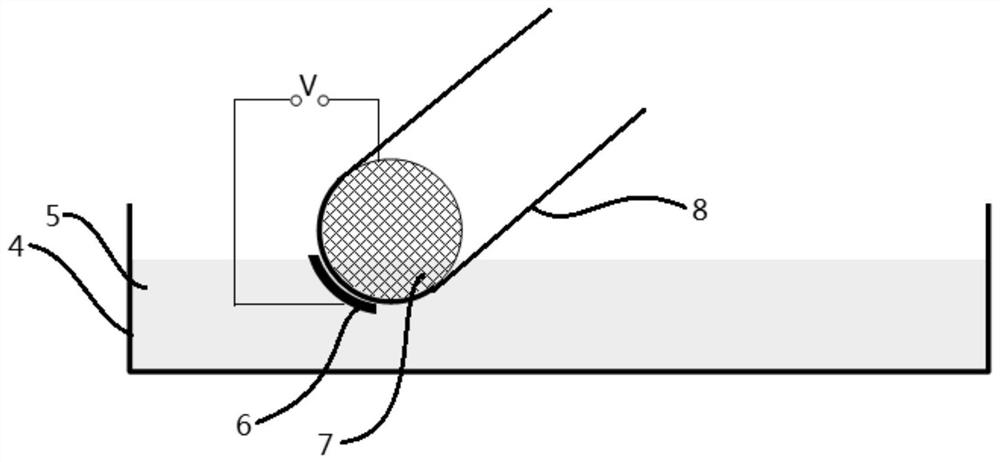

[0034] Such as figure 2 As shown, the PEO coating of the prepared composite membrane was subjected to electrochemical fluorination treatment. Pass the prepared composite film 8 through the nickel-plated counter-roller 7, and partially immerse it in the Olah reagent solution 5, and the electrolytic cell 4 is made of polytetrafluoroethylene. Olah's reagent is C 5 h 5 N . HF (pyridinium polyhydrofluoride), wherein the HF content is 70%. The composite film 8 is close to the nickel anode 6 at the part facing the roller. Apply a voltage of 5V and a current of 0.5A in the electrolytic cell 4, and rotate slowly at a speed of 0.2m / min, so that the electrochemic...

Embodiment 2

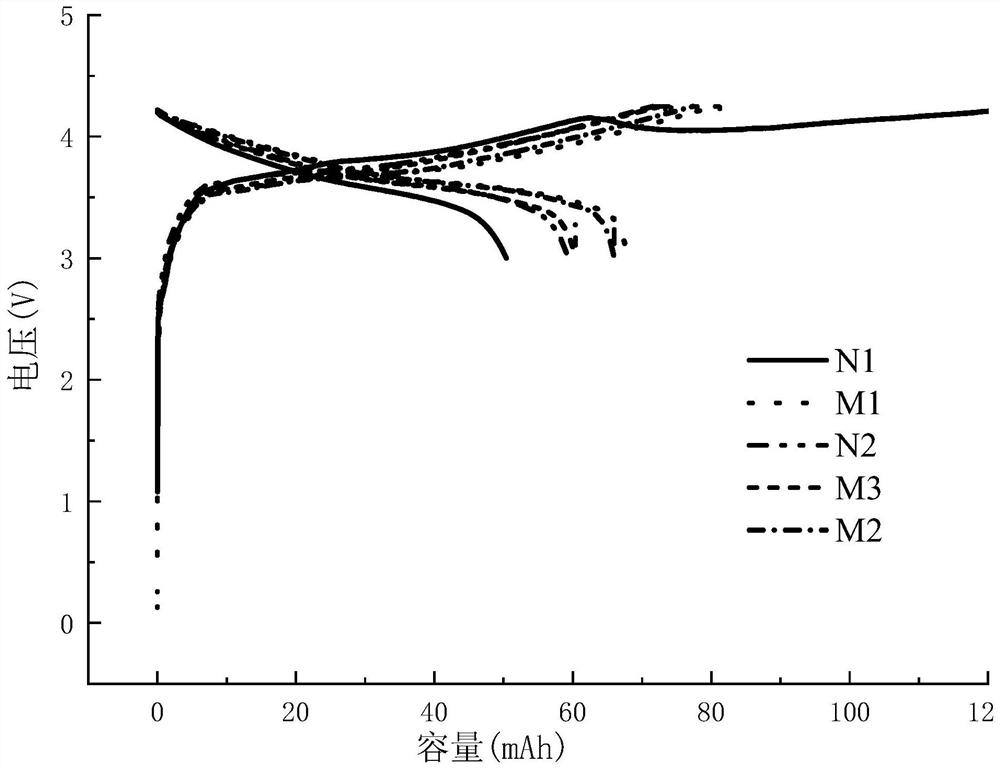

[0037] Except that the electrochemical fluorination treatment is different from Example 1, other preparation processes are the same as Example 1. The electrochemical fluorination process in this embodiment is as follows: apply a voltage of 5V in the electrolytic cell, a current of 1A, and slowly rotate at a speed of 0.2m / min to obtain the first polyethylene oxide film 2 with an F content of 142ppm.

Embodiment 3

[0039] Except that the electrochemical fluorination treatment is different from Example 1, other preparation processes are the same as Example 1. The electrochemical fluorination process in this embodiment is as follows: apply a voltage of 5V in the electrolytic cell, a current of 3A, and slowly rotate at a speed of 0.15m / min to obtain a PEO film with an F content of 442ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com