Low-temperature CO-SCR denitration Cu-Ni/AC catalyst and preparation method thereof

A CO-SCR and catalyst technology, which is applied in the field of low-temperature CO-SCR denitrification Cu-Ni/AC catalyst and its preparation, can solve the problems of corrosion reducing agent, low denitrification performance, toxicity, etc., and achieve the improvement of active functional groups and nitrogen selection Good performance and increase the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: preparation carrier coconut shell activated carbon (AC)

[0046] 1: Take coconut shell activated carbon, impregnate according to the material-liquid ratio of 1g (coconut shell activated carbon): 5ml (deionized water), shake and wash in an ultrasonic water bath at 60°C for 60min, and dry at 110°C for 12h after suction filtration. Get clean activated carbon.

[0047] 2: Activate the cleaned activated carbon under air atmosphere at 350°C for 2 hours to obtain carrier activated carbon.

Embodiment 2

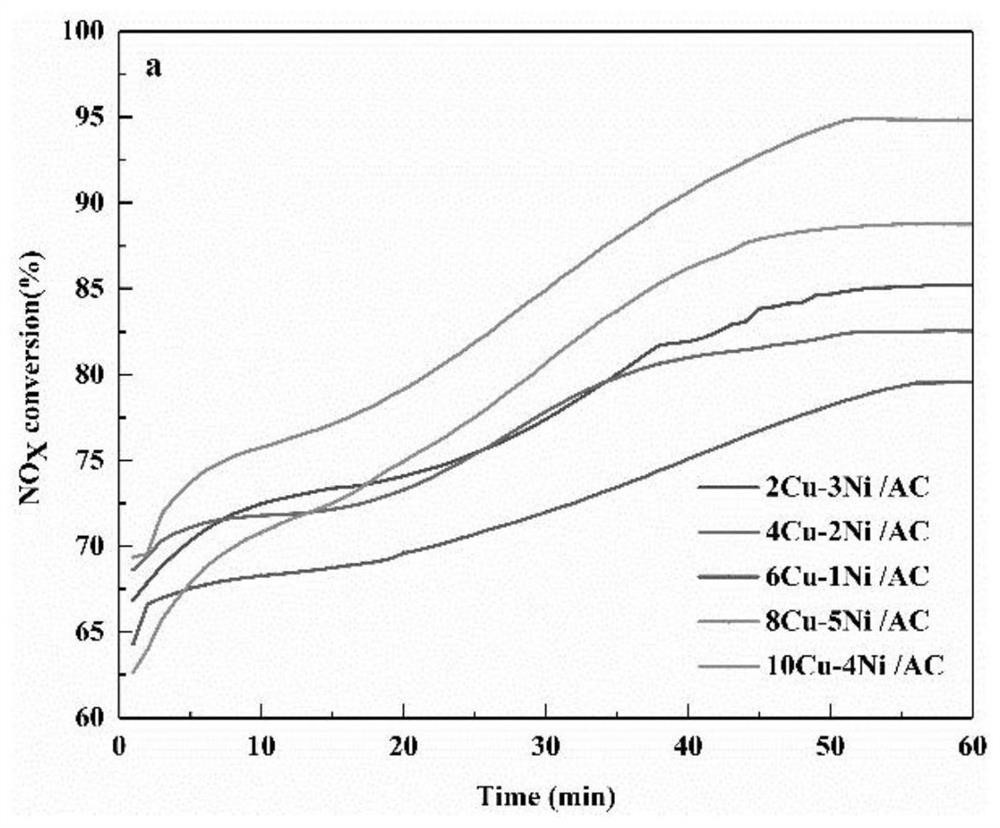

[0048] Example 2: Preparation of a low-temperature CO-SCR denitrification Cu-Ni / AC catalyst

[0049] 1: Dissolve an appropriate amount of copper nitrate and nickel acetate in deionized water, make it into a modified solution of 0.04-0.2g / ml, and then impregnate it with a material-to-liquid ratio of 1g (AC): 2.5ml (modified solution) , and then shaken in an ultrasonic water bath for 60 minutes, and then dried at 110° C. for 12 hours after suction filtration to obtain the initial product.

[0050] 2: The initial product was roasted at 450°C for 4h under the protection of nitrogen to prepare a low-temperature CO-SCR denitrification Cu-Ni / AC catalyst.

Embodiment 3

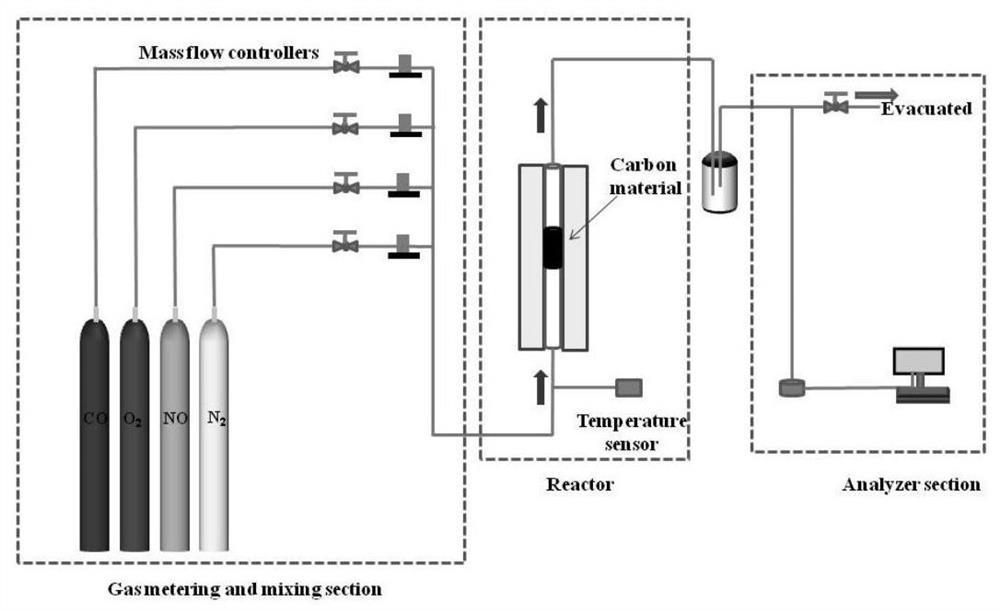

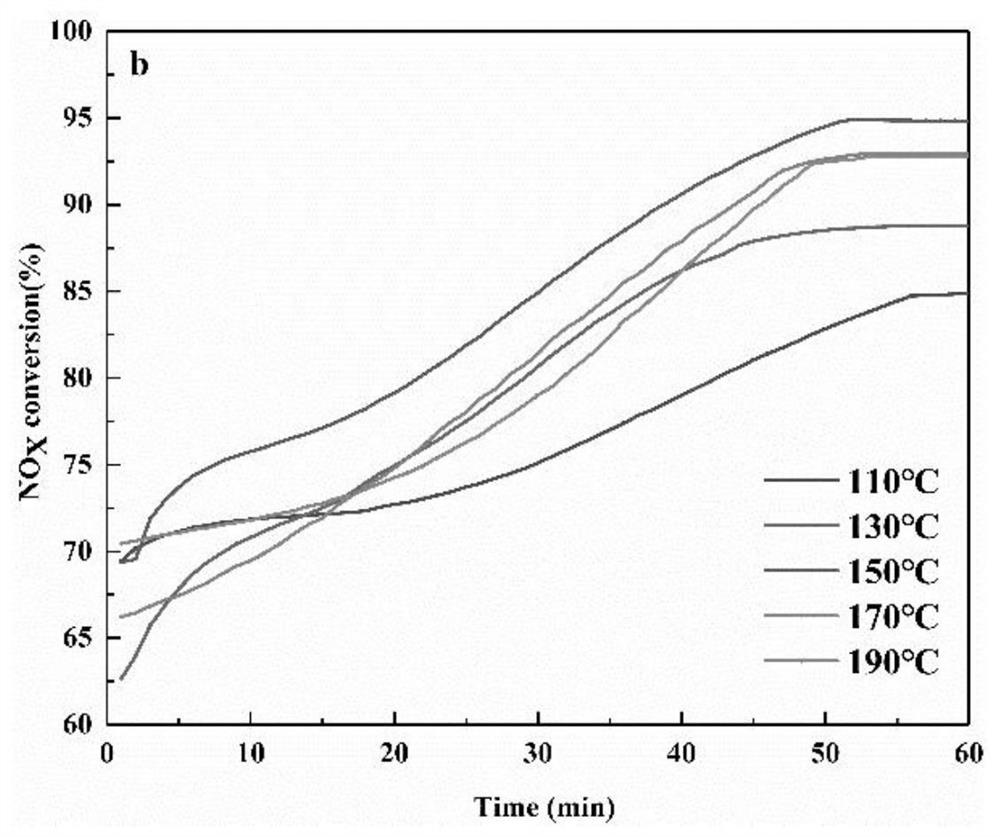

[0051] Example 3: Evaluation of fixed bed reactors.

[0052] The low-temperature CO-SCR denitrification Cu-Ni / AC catalyst and coconut shell activated carbon (purchased from Henan Gongyi Blue Sky Water Purification Technology Co., Ltd.) prepared in Example 2 were used as denitration reaction materials, and the denitration reaction experiments were carried out at 100-190 ° C, respectively. The loading amount of the catalyst is 10 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com