Method for hydrotreating butanol and octanol raffinate

A technology for hydrotreating and residual liquid, applied in chemical instruments and methods, chemical/physical processes, preparation of organic compounds, etc., can solve the problems of poor recovery efficiency of butanol residual liquid, save resources and improve recycling Efficiency, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

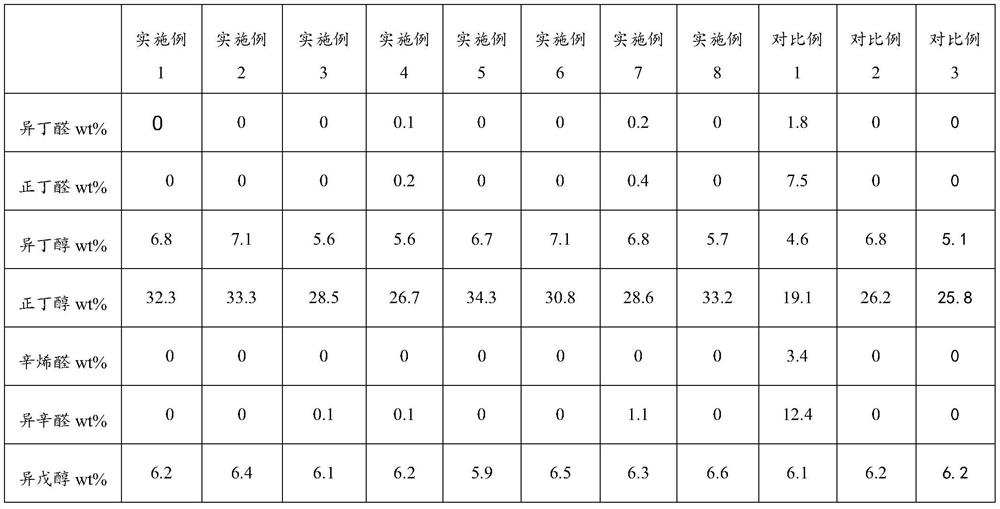

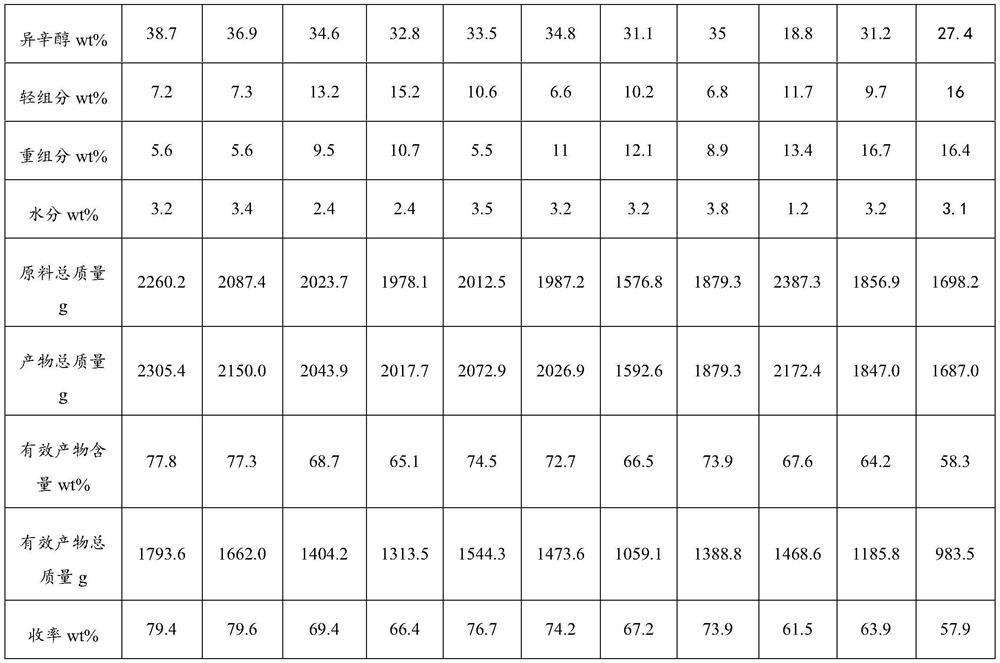

Examples

Embodiment 1

[0039] The present embodiment provides a method for hydrotreating butanol raffinate, comprising the steps of:

[0040] Preparation of supported catalyst:

[0041] Use aluminum nitrate to prepare 1L of aluminum nitrate aqueous solution containing aluminum 171.9g / L;

[0042] Use copper nitrate to prepare 1L of copper nitrate aqueous solution containing copper 140.0g / L;

[0043] Use sodium carbonate to prepare the precipitant aqueous solution containing sodium carbonate 156.5g / L;

[0044] Mix the above-mentioned aluminum nitrate aqueous solution and copper nitrate aqueous solution evenly, heat to 50° C., add the precipitant aqueous solution at a stirring rate of 200 rpm, and stop adding the precipitant aqueous solution when the pH value of the reaction solution reaches 8.5. Continue co-precipitation at this temperature and stirring state for 2 hours; filter and wash the precipitate with water; then dry at 120°C for 6 hours, and roast at 550°C for 6 hours in a nitrogen atmospher...

Embodiment 2

[0051] The present embodiment provides a method for hydrotreating butanol raffinate, comprising the steps of:

[0052] Preparation of supported catalyst:

[0053] 300 mesh copper oxide powder 112.5g and 300 mesh TiO 2 Mix 110g of powder, add 15g of water, and knead for 30min to obtain a mixture;

[0054] Send the above-mentioned mixture into an extruder to extrude and shape to obtain a molded product;

[0055] After drying the molding at 120°C for 4 hours, it was calcined at 500°C for 6 hours to obtain 200g of a catalyst with a mass content of 45% copper as the active component.

[0056] Detected by the BET method specific surface area analyzer, the specific surface area of the above-mentioned supported catalyst is 55m 2 / g.

[0057] Hydrotreating butanol raffinate:

[0058] The butanol raffinate is adjusted to a pH of 6.5 with an aqueous solution of trimethylamine containing 70 wt % of water to obtain the butanol raffinate after the pH adjustment for subsequent use;

...

Embodiment 3

[0062] The present embodiment provides a method for hydrotreating butanol raffinate, comprising the steps of:

[0063] Preparation of supported catalyst:

[0064] Prepare 200ml of copper nitrate aqueous solution containing 150.0g / L of copper; then put 162.4g of silicon dioxide into the above-mentioned copper nitrate aqueous solution, soak at a constant temperature of 50°C for 1h, and then dry the impregnated silicon dioxide at 120°C for 4h, Calcined at 450° C. for 4 hours to obtain 200 g of a supported catalyst with a mass content of 15% copper as the active component.

[0065] Detected by the BET method specific surface area analyzer, the specific surface area of the above-mentioned supported catalyst is 125m 2 / g.

[0066] Hydrotreating butanol raffinate:

[0067] The butanol raffinate is adjusted to a pH of 7.0 by using an aqueous solution of trimethylamine containing 70 wt % of water to obtain the butanol raffinate after adjusting the pH for subsequent use;

[0068] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com