Method and equipment for obtaining ethylene glycol and diethylene glycol from recovered solution

A technology for recovering liquid and ethylene glycol, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of ether, etc. It can solve problems such as waste of EG and DEG, environmental pollution, complex components of transesterification products, etc., and achieve work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

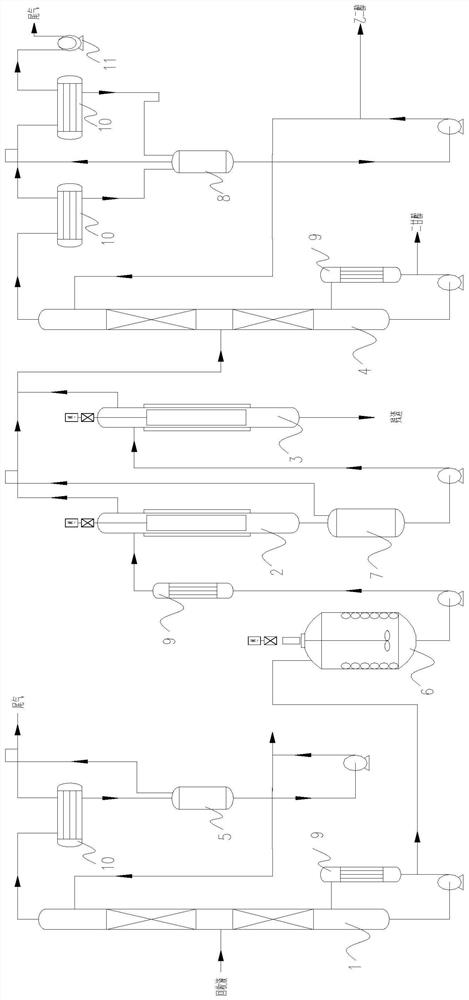

[0056] Embodiment 1 Obtain the equipment of ethylene glycol and diethylene glycol in a kind of recovered liquid

[0057] Such as figure 1 As shown, the equipment includes a first rectification tower 1, a first thin-film evaporator 2, a second thin-film evaporator 3, and a second rectification tower 4, and the first rectification tower 1 is connected to the recovery liquid inlet, and the recovery The liquid enters the first rectification tower 1, and the 180°C atmospheric rectification process first removes methanol in the gaseous phase. After the methanol is condensed, it is collected in the methanol storage tank 5 to obtain the first mixed liquid. The output of the first rectification tower 1 end is connected with the liquid inlet end of the first mixed liquid storage tank 6, and the liquid outlet end of the first mixed liquid storage tank 6 is connected with the liquid inlet end of the first thin film evaporator 2, and the first thin film evaporator 2 The liquid inlet end i...

Embodiment 2

[0059] Embodiment 2 reclaims ethylene glycol and diethylene glycol from recovery liquid

[0060] Atmospheric rectification: The recovered liquid in the reaction kettle passes through the rectification tower and undergoes atmospheric rectification at 160°C to separate the first gas phase substance methanol to obtain the first mixed liquid, which is temporarily stored in the first mixed liquid storage tank , the first atmospheric distillation step separates methanol as a gas phase.

[0061] Negative pressure evaporation: lift the first mixed solution through the lift pump, and preheat the heater at 180°C, then enter the first thin film evaporator through the liquid inlet end of the first thin film evaporator, and the first mixed solution evaporates through the first thin film The evaporator obtains the first steam and the first evaporated liquid, and the first evaporated liquid flows into the intermediate storage tank, and then is transported to the second thin film evaporator t...

Embodiment 3

[0064] Embodiment 3 reclaims ethylene glycol and diethylene glycol from recovery liquid

[0065] Atmospheric rectification: The recovered liquid in the reaction kettle passes through the rectification tower and undergoes atmospheric rectification at 160°C to separate the first gas phase substance methanol to obtain the first mixed liquid, which is temporarily stored in the first mixed liquid storage tank , the first atmospheric distillation step separates methanol as a gas phase.

[0066] Negative pressure evaporation: lift the first mixed solution through the lift pump, and preheat the heater at 160°C, then enter the first thin film evaporator through the liquid inlet end of the first thin film evaporator, and the first mixed solution evaporates through the first thin film The evaporator obtains the first steam and the first evaporated liquid, and the first evaporated liquid flows into the intermediate storage tank, and then is transported to the second thin film evaporator t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com