Air purification degerming mildew-proof coating and preparation method thereof

An air purification and anti-mildew technology, applied in the field of coatings, can solve the problems of high cost of enterprises, achieve the effect of improving anti-mildew performance, inhibiting the growth of fungi, and good anti-mildew performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

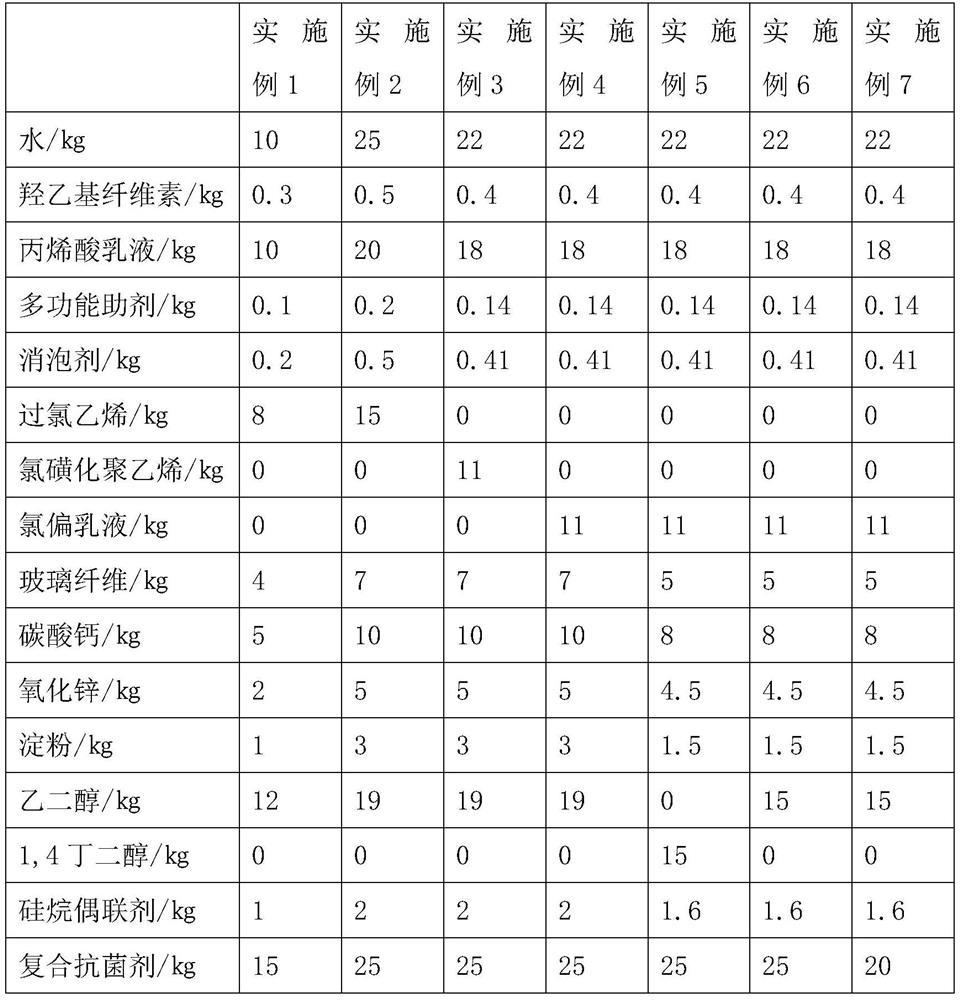

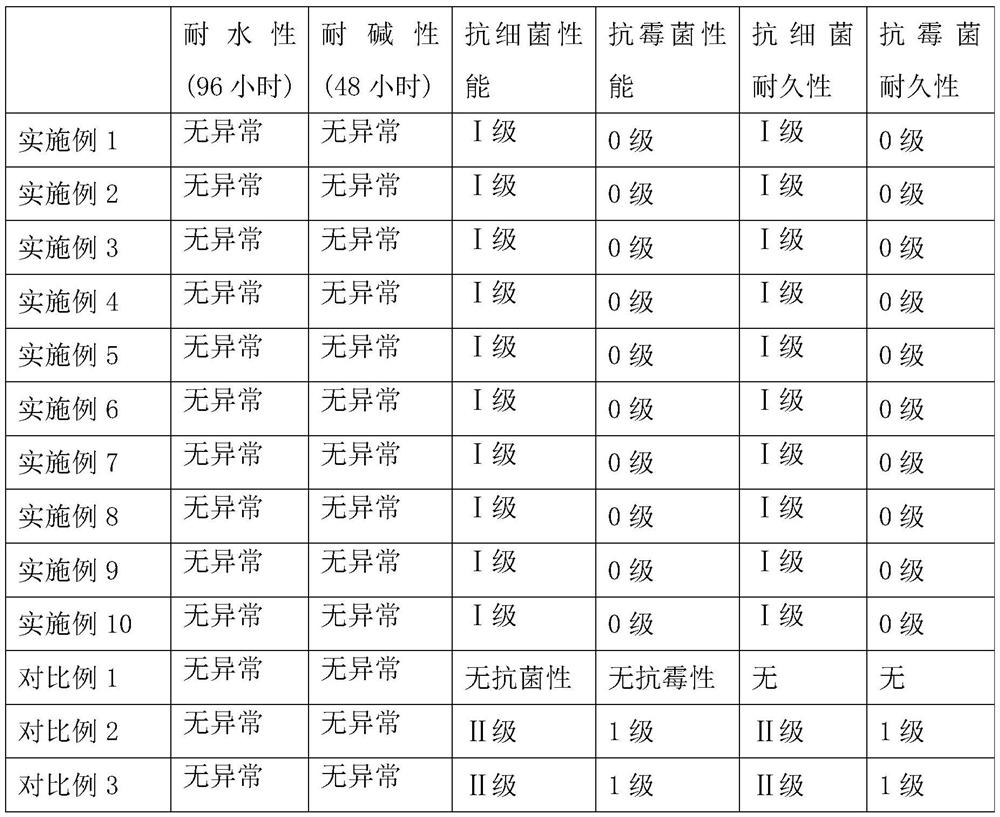

Examples

preparation example 1

[0046] The preparation method of composite antibacterial agent comprises the following steps:

[0047] Step 1, boil water, cloves, paeonol and camphor leaves, wherein the mass ratio of water, cloves, paeonol and camphor leaves is 1:1:2:2, then time the water to boil, boil for 20min, then cool Filter the juice below 40°C;

[0048] In step 2, the bovine bone powder, shell powder and juice are subjected to ultrasonic treatment, and after mixing and homogenizing, a slurry is prepared, and the mass ratio of bovine bone powder and shell powder is 1:1.

preparation example 2

[0050] The preparation method of composite antibacterial agent comprises the following steps:

[0051] Step 1, boil water, cloves, paeonol and camphor leaves, wherein the mass ratio of water, cloves, paeonol and camphor leaves is 2:1:1:1, then time the water to boil, boil for 20min, then cool Filter the juice below 40°C;

[0052] In step 2, the bovine bone powder, shell powder and juice are subjected to ultrasonic treatment, and after mixing and homogenizing, a slurry is prepared, and the mass ratio of bovine bone powder and shell powder is 1:1.

preparation example 3

[0054] The preparation method of composite antibacterial agent comprises the following steps:

[0055] Step 1, boil water, cloves, paeonol and camphor leaves, wherein the mass ratio of water, cloves, paeonol and camphor leaves is 2:1:1:1, then time the water to boil, boil for 20min, then cool Filter the juice below 40°C;

[0056] In step 2, the bovine bone powder, shell powder and juice are subjected to ultrasonic treatment, mixed and homogenized to obtain a slurry, and the mass ratio of bovine bone powder and shell powder is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com