Photonic crystal structure chromogenic fabric and preparation method thereof

A technology of photonic crystals and structural coloration, applied in textiles and papermaking, fiber treatment, fiber types, etc., can solve the problems of restricting large-scale industrial applications, high investment in equipment at one time, complicated preparation process, etc., to avoid VOCs pollution problems, Reduced energy waste and the effect of excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a photonic crystal structure color-producing fabric, the specific steps of the method are:

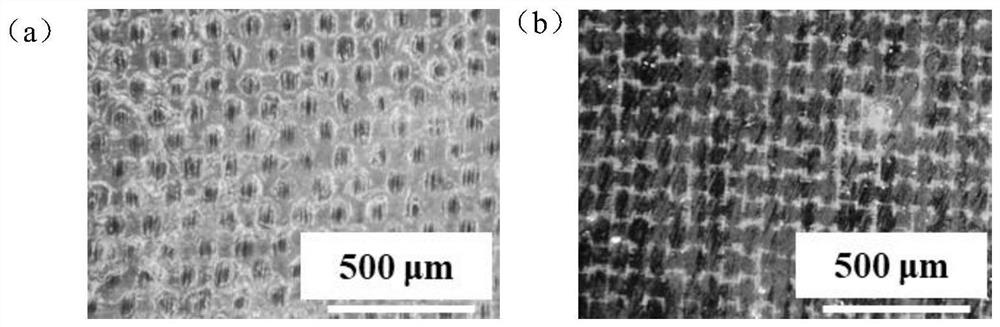

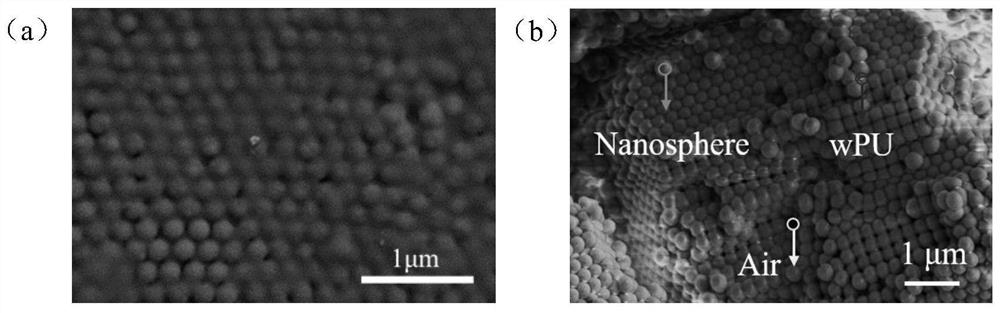

[0039] (1) Prepare a dispersion of 0.5% photonic crystal structure unit 290nm PS nanospheres, and construct a photonic crystal structure on the surface of polyester textile substrate by impregnation method at a temperature of 50°C and a humidity of 50%;

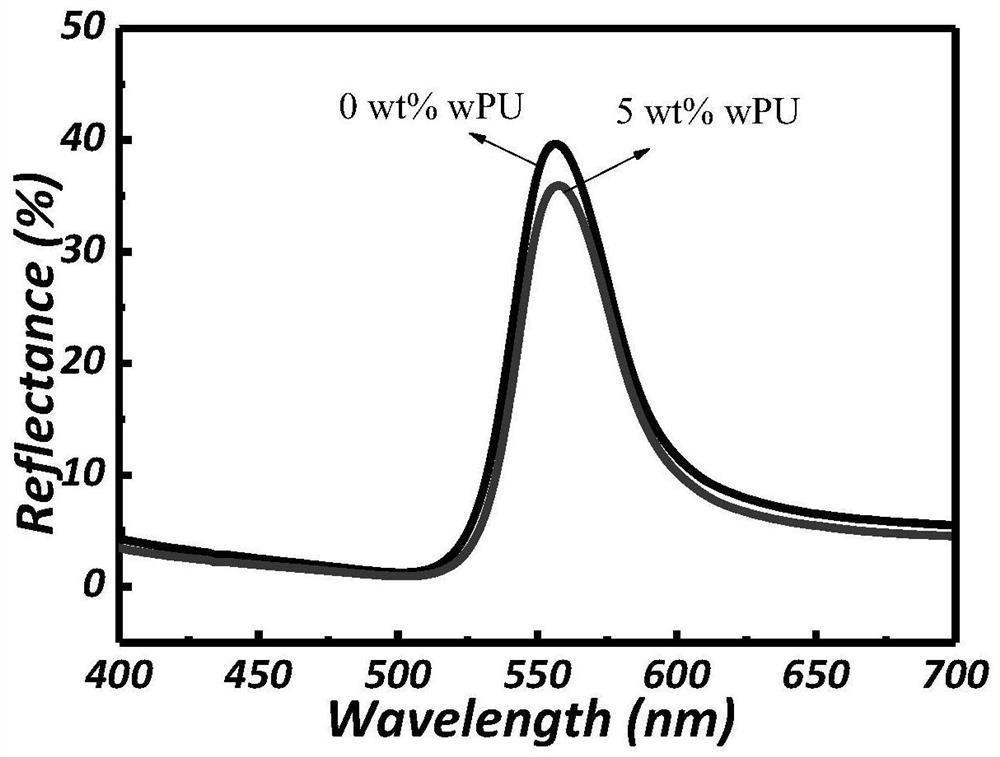

[0040] (2) Prepare a water-based polyurethane PUE1401 solution and apply it on the surface of the photonic crystal structure chromogenic fabric, the mass fraction of the water-based polyurethane solution is 0.5%;

[0041] (3) Put the color-producing fabric with photonic crystal structure coated with encapsulant in a drying device for drying and curing. The drying temperature was set at 50°C.

Embodiment 2

[0043] A method for preparing a photonic crystal structure color-producing fabric, the specific steps of the method are:

[0044] (1) Prepare 1% photonic crystal structure unit 240nm SiO 2 Dispersion of nano-microspheres, and build a photonic crystal structure on the surface of polyester textile substrate by impregnation method, temperature 60 ℃, humidity 60%;

[0045] (2) Prepare a water-based acrylate solution and apply it on the surface of the photonic crystal structure chromogenic fabric, the mass fraction of the water-based acrylate solution is 1%;

[0046] (3) Put the color-producing fabric with photonic crystal structure coated with encapsulant in a drying device for drying and curing. The drying temperature was set at 60°C.

Embodiment 3

[0048] A method for preparing a photonic crystal structure color-producing fabric, the specific steps of the method are:

[0049] (1) Prepare a 200nm PMMA nanosphere dispersion liquid with 28% photonic crystal structure unit, and build a photonic crystal structure on the surface of polyester textile substrate by scraping method at a temperature of 70°C and a humidity of 70%;

[0050] (2) Prepare a water-based silicone solution and apply it on the surface of the photonic crystal structure color-producing fabric. The massfraction of aqueous organic silicon solution is 2%;

[0051] (3) Put the color-producing fabric with photonic crystal structure coated with encapsulant in a drying device for drying and curing. The drying temperature was set at 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com