Magnesium lithium silicate pre-lithiated silicon monoxide negative electrode material as well as preparation method and application thereof

A silicon oxide, negative electrode material technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of active lithium loss, volume expansion of silicon-based negative electrodes, poor cycle performance, etc., and achieve high electronic and ionic conductivity. , the effect of easy insertion and extraction, high first coulomb efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

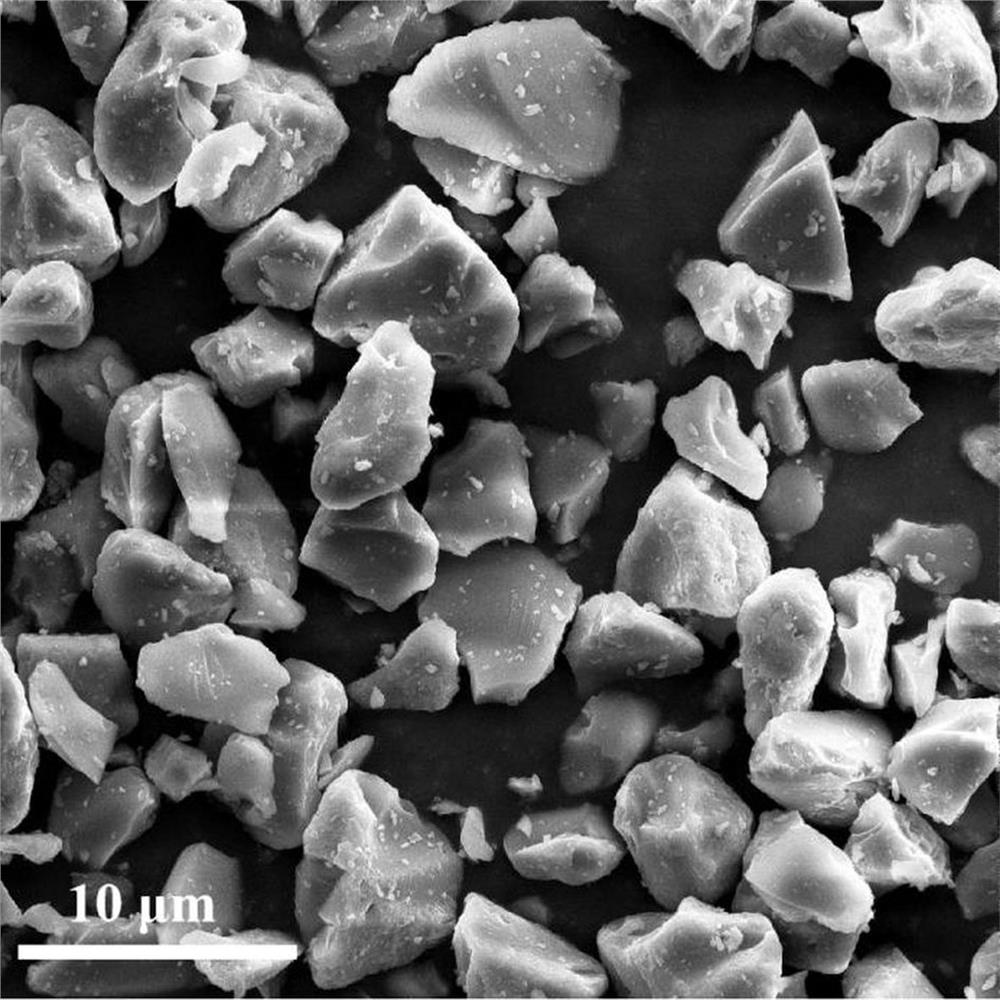

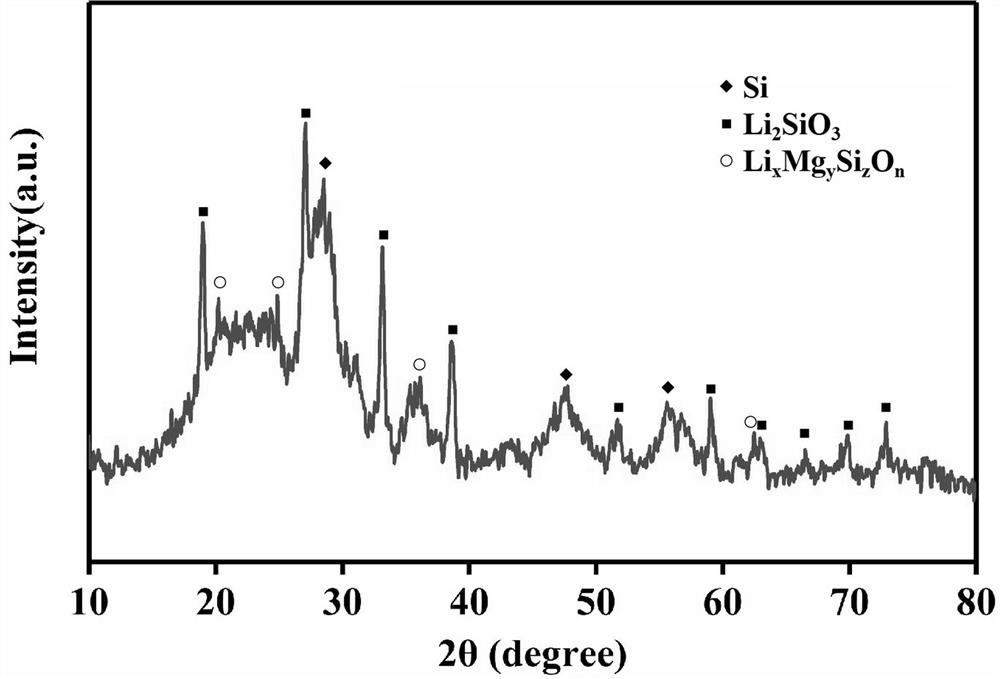

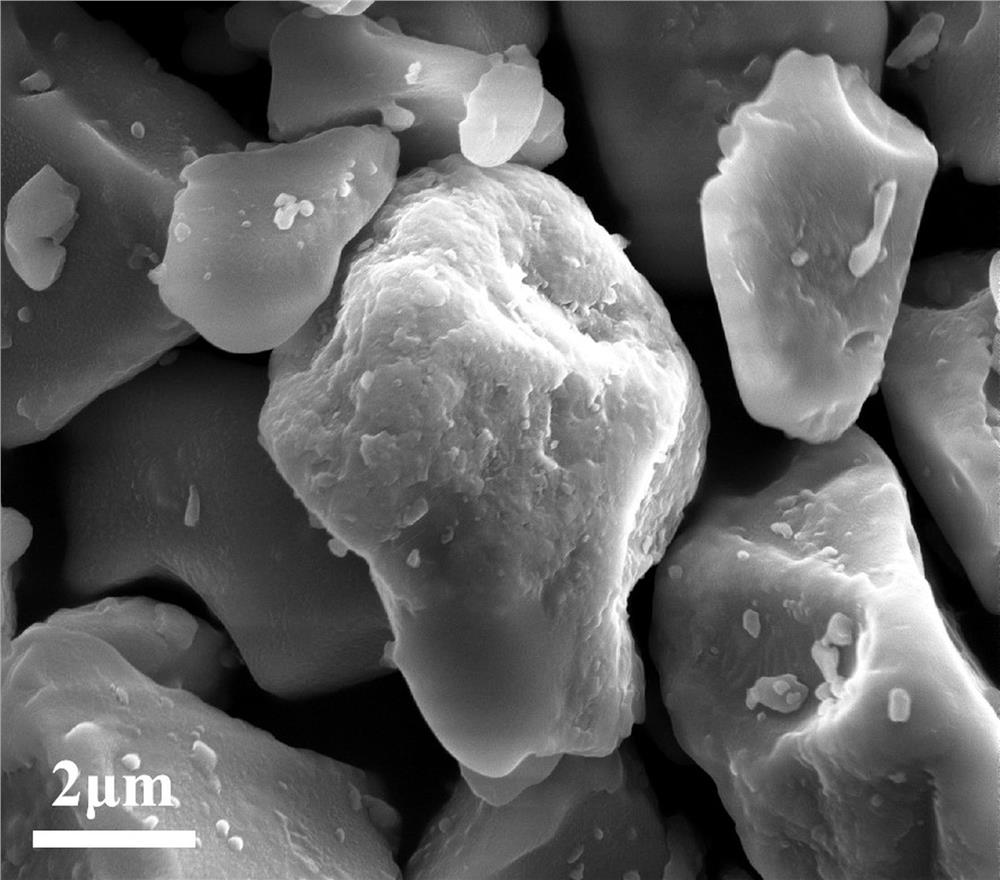

[0029] This embodiment 1 provides a method for preparing lithium magnesium silicate pre-lithiated silicon oxide negative electrode material, which specifically includes the following steps:

[0030] (1) Take a certain amount of commercial silicon oxide powder, magnesium oxide powder and lithium oxide powder, put them into the mixer according to the molar ratio of 5:2:1, the speed of the mixer is 200rpm / min, and the mixing time is Mix the three in 2 hours to obtain powder A of uniform composition;

[0031] (2) Take 10g of the powder A obtained in step (1) and place it in a corundum mullite crucible for heat treatment. The atmosphere is high-purity argon. The duration is the entire heating process and the entire cooling process, and the heating rate is 5 ℃ / min, the heat treatment temperature is 1200°C, the holding time is 5 hours, and the intermediate product B-1 is obtained after calcination;

[0032] (3) The intermediate product B prepared in step (2) is coated with carbon b...

Embodiment 2

[0034] The preparation process of Example 2 is exactly the same as that in Example 1, except that the molar ratio of silicon oxide powder, magnesium oxide powder and lithium oxide powder in step (1) is 4:2:1.

[0035] It can be seen through testing that the appearance of the product is similar to that of the final product prepared in Example 1.

Embodiment 3

[0037] The preparation process of Example 3 is exactly the same as that in Example 1, except that the molar ratio of silicon oxide powder, magnesium oxide powder and lithium oxide powder in step (1) is 6:2:1.

[0038] It can be seen through testing that the appearance of the product is similar to that of the final product prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com