Molluscicide

A molluscicide and chelating agent technology, applied in the field of pesticides, can solve the problems of skin irritation, eye pollution, groundwater pollution, poor degradability, etc., and achieve the effect of ensuring harmlessness and safety, and improving solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

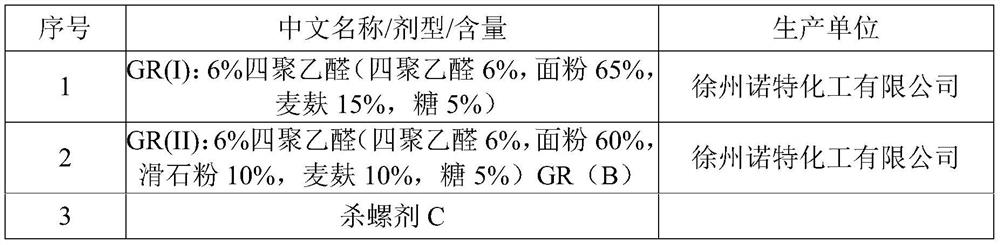

Image

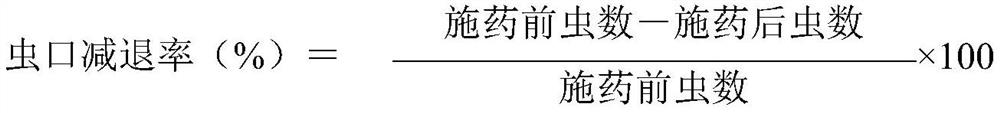

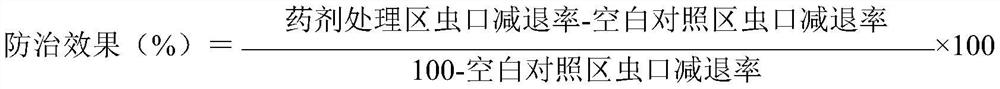

Examples

Embodiment 1

[0050] The present embodiment provides a kind of ferric phosphate chelate molluscicide, it is granule, is denoted as molluscicide A, by mass percentage, its raw material is composed of:

[0051] (1) In the iron phosphate chelate, the mass percentages of iron phosphate and GLDA are respectively 10%: 15%

[0052] (2) filler wheat starch 60%

[0053] (3) Adhesive sodium carboxymethyl cellulose 2%

[0054] (4) Lubricant vegetable oil 3%

[0055] (5) Pigment 0.5%

[0056] (6) Water 9.5%.

[0057] The molluscicide of the present embodiment is prepared according to the following steps: 1. Accurately weigh each component weight in proportion; 2. Mix and stir the weighed ferric phosphate and chelating agent for 15 minutes to form ferric phosphate chelate ; Mix the water and the pigment for 5 minutes; then mix the chelated chelate, the mixture of water and pigment, the filler, the binder, and the lubricant in batches in proportion, and stir for 40 minutes; 3. Then mix the material ...

Embodiment 2

[0059] The present embodiment provides a kind of ferric phosphate chelate molluscicide, it is granule, is denoted as molluscicide B, and by mass percentage, its raw material is composed of:

[0060] (1) In the iron phosphate chelate, the mass percentages of iron phosphate and GLDA are respectively 5%: 10%

[0061] (2) filler corn starch 68%

[0062] (3) Adhesive sodium carboxymethyl cellulose 4%

[0063] (4) Lubricant vegetable oil 3%

[0064] (5) Pigment 0.5%

[0065] (6) Water 9.5%.

[0066] The molluscicide of the present embodiment is prepared according to the following steps: 1. Accurately weigh each component weight in proportion; 2. Mix and stir the weighed ferric phosphate and chelating agent for 15 minutes to form ferric phosphate chelate ; Mix water and pigment for 5 minutes; Mix the chelated chelate, water and pigment mixture, filler, adhesive, lubricant in batches and stir for 40 minutes; 3. Transport the material to Granulation by granulator; 4. Drying for 10...

Embodiment 3

[0068] The present embodiment provides a kind of ferric phosphate chelate molluscicide, it is granule, is denoted as molluscicide C, by mass percentage, its raw material is composed of:

[0069] (1) In the iron phosphate chelate, the mass percentages of iron phosphate and GLDA are respectively 2%: 2%

[0070] (2) Filler modified starch 80%

[0071] (3) Adhesive sodium carboxymethyl cellulose 3%

[0072] (4) Lubricant vegetable oil 3%

[0073] (5) Pigment 0.5%

[0074] (6) Water 9.5%.

[0075] The molluscicide of the present embodiment is prepared according to the following steps: 1. Accurately weigh each component weight in proportion; 2. Mix and stir the weighed ferric phosphate and chelating agent for 15 minutes to form ferric phosphate chelate ; Mix water and pigment for 5 minutes; Mix the chelated chelate, water and pigment mixture, filler, adhesive, lubricant in batches and stir for 40 minutes; 3. Transport the material to Granulation by granulator; 4. Drying for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com