Rumen slow-release nutrition bar and preparation method thereof

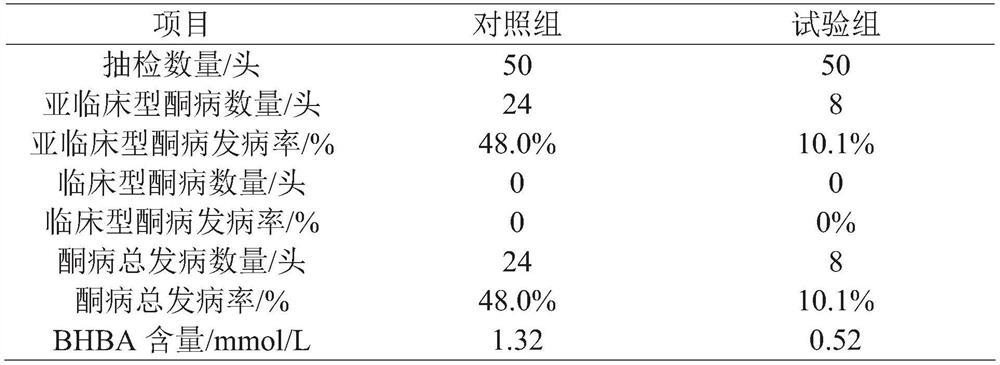

A slow-release nutrition and rumen technology, which is applied in the field of rumen slow-release nutrition bar and its preparation, can solve the problems of insufficient prevention and treatment of ketosis, poor slow-release effect of nutrients, etc., to reduce the burden on the liver, reduce fat decomposition, reduce The effect of feeding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

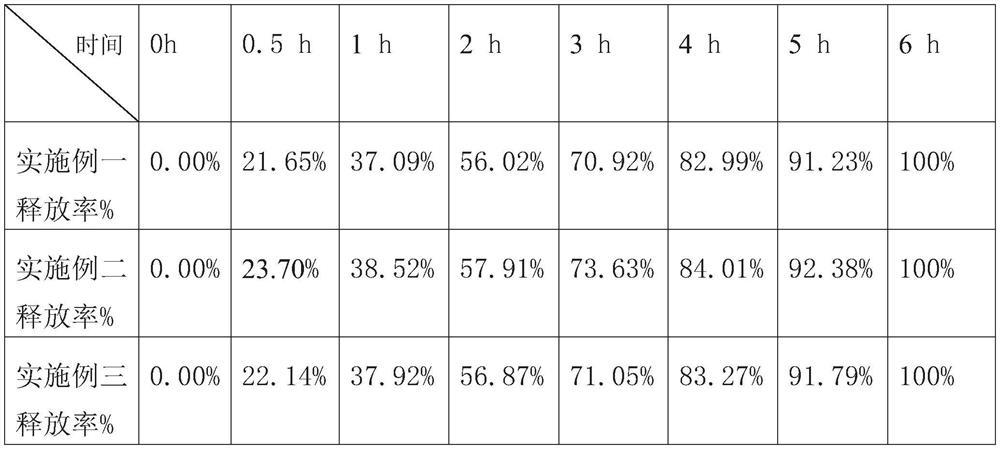

Embodiment 1

[0022] A preparation method of a rumen slow-release nutrition bar, comprising the following steps:

[0023] 1) 40 parts by weight of liquid choline chloride with a content of 75% and 50 parts by weight of gelatinized starch are wet granulated and dried to obtain granular choline chloride; 70 parts by weight of calcium propionate and 20 parts by weight of 40 parts by weight of propylene glycol and 40 parts by weight of gelatinized starch are wet granulated and dried to obtain granulated propylene glycol, and the above granules are 32-40 mesh;

[0024] 2) After mixing 5 parts by weight of cornstarch, 2 parts by weight of soybean lecithin, 4 parts by weight of microcrystalline cellulose, 5 parts by weight of calcium hydrogen phosphate and 70 parts by weight of polyethylene glycol 4000, heated to 100 ° C and stirred for 15 minutes, Obtain the slow-release adhesive solution and store it at 90°C;

[0025] 3) Take 20 parts by weight of granular choline chloride prepared in step 1),...

Embodiment 2

[0027] A preparation method of a rumen slow-release nutrition bar, comprising the following steps:

[0028] 1) 50 parts by weight of liquid choline chloride with a content of 75% and 50 parts by weight of gelatinized starch are wet granulated and dried to obtain granular choline chloride; 100 parts by weight of calcium propionate and 20 parts by weight of 40 parts by weight of propylene glycol and 60 parts by weight of gelatinized starch are wet granulated and dried to obtain granulated propylene glycol, and the above granules are 32-40 mesh;

[0029] 2) After mixing 5 parts by weight of cornstarch, 2 parts by weight of soybean lecithin, 4 parts by weight of microcrystalline cellulose, 7 parts by weight of calcium hydrogen phosphate and 82 parts by weight of polyethylene glycol 4000, heated to 100 ° C, stirred for 15 minutes, Obtain the slow-release adhesive solution and store it at 90°C;

[0030] 3) Take 20 parts by weight of granular choline chloride prepared in step 1), 8...

Embodiment 3

[0032] A preparation method of a rumen slow-release nutrition bar, comprising the following steps:

[0033] 1) get 45 parts by weight of liquid choline chloride with a content of 75% and 55 parts by weight of gelatinized starch to carry out wet granulation and dry to obtain granular choline chloride; 80 parts by weight of calcium propionate and 30 parts by weight of 50 parts by weight of propylene glycol and 50 parts by weight of gelatinized starch are wet granulated and dried to obtain granulated propylene glycol, and the above granules are 32-40 mesh;

[0034] 2) Mix 6 parts by weight of cornstarch, 4 parts by weight of soybean lecithin, 5 parts by weight of microcrystalline cellulose, 6 parts by weight of calcium hydrogen phosphate and 90 parts by weight of polyethylene glycol 4000, heat to 100 ° C, and stir for 20 minutes. Obtain the slow-release adhesive solution and store it at 90°C;

[0035] 3) Take 30 parts by weight of granular choline chloride prepared in step 1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com