Cold-soaking instant protein powder and preparation method thereof

A protein powder and cold foam technology, which is applied in the field of protein powder production, can solve the problems of improving the dispersibility and solubility of protein powder, deepening the color of protein powder, and being difficult to disperse quickly, and achieves optimized high dispersibility, high solubility, high Dispersibility and solubility, the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method of the instant protein powder of cold brew provided by the invention, its preparation method comprises the following steps:

[0039] Step 1, pre-mix soybean lecithin powder and main protein powder and prepare mixed solution A;

[0040] Step 2, pre-mixing water-soluble dietary fiber and modified starch to obtain a mixed solution B;

[0041] Step 3: Spray the mixed solution A and the mixed solution B on the main protein powder to obtain instant cold-brewed protein powder.

[0042] Preferably, the specific steps of said step 3 include:

[0043] Step 3-1, the first spraying step: using the first spraying condition, the mixed liquid A is sprayed on the main protein powder to obtain the pre-coated protein powder, wherein the first spraying condition is: the atomization pressure is 0.8-1.2MPa, spray flow rate 5-200mL / min, air inlet temperature 50-100℃, air inlet volume 10-200m 3 / h, the drying time is 10-30min; as a natural emulsifier, soybean l...

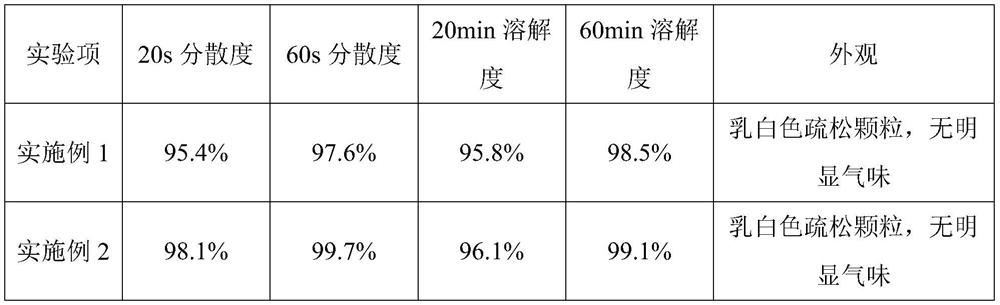

Embodiment 1

[0063] Embodiment 1: A cold-brew instant protein powder provided by this embodiment, which includes a main protein powder prescription of 100 kg, 10 kg of water-soluble dietary fiber, 3 kg of modified starch and 1 kg of soybean lecithin powder; wherein the main protein powder includes soybean Protein isolate powder 70kg and whey protein concentrate powder 30kg;

[0064] Its preparation method comprises the following steps:

[0065] Step 1: Take 1kg of soybean lecithin powder and 1kg of main protein powder for pre-mixing treatment to obtain mixed powder a; add 60°C pure water according to the mass fraction of 10% of the mixed powder a, stir rapidly until dissolved to form a high-concentration slurry, Stand still for 40 minutes; transfer the high-concentration slurry to a high-pressure homogenizer, homogenize twice at 160MPa, prepare a mass fraction of 15%, and homogenize twice at 60MPa to obtain the mixed solution A , and kept at 60°C for later use;

[0066] Step 2, taking 10...

Embodiment 2

[0068] Embodiment 2: a kind of cold bubble instant protein powder that this embodiment provides, it comprises that main protein powder formula quantity is 100kg, water-soluble dietary fiber 12kg, modified starch 4kg and soybean lecithin powder 1.5kg; Wherein main protein powder is soy protein isolate powder;

[0069] Its preparation method comprises the following steps:

[0070] Step 1: Take 1.5kg of soybean lecithin powder and 1.5kg of main protein powder for pre-mixing treatment to obtain mixed powder a; add pure water at 50°C according to the mass fraction of 15% of the mixed powder a, and stir quickly until dissolved to form a high concentration Slurry, let it stand for 30min; transfer the high-concentration slurry to a high-pressure homogenizer, homogenize twice at 170MPa, prepare a mass fraction of 20%, and homogenize twice at 75MPa to obtain the mixed solution A, and keep it warm at 50°C for later use;

[0071] Step 2, taking 12kg of water-soluble dietary fiber and 4k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com