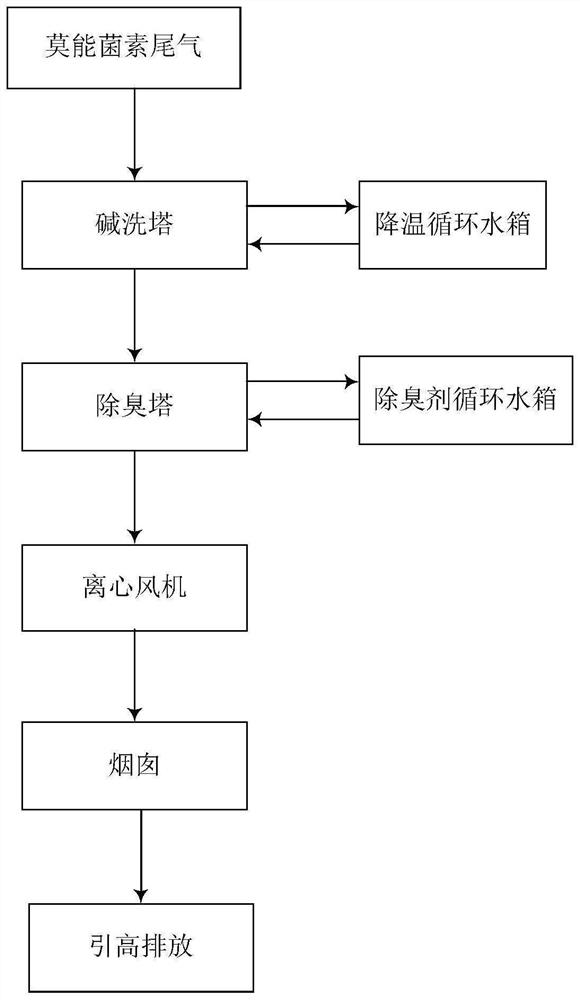

Monensin tail gas treatment process

A monensin and exhaust gas treatment technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problem that the specific odor cannot be well eliminated, does not meet the objective needs of protecting the environment, and does not meet the exhaust gas. Handling and other issues to achieve good results that are conducive to stability, good handling, and elimination of odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

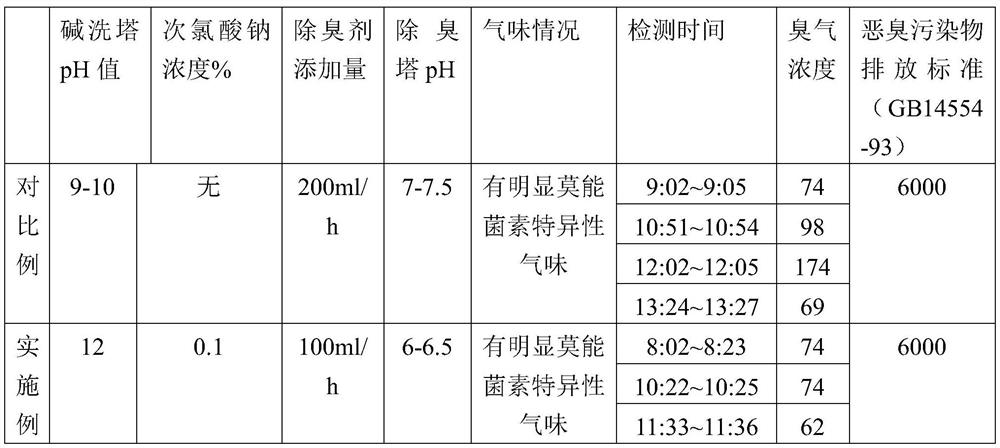

Embodiment 1

[0022] The tail gas produced by monensin is collected and transported to the alkali washing tower, and the pH value of the treatment liquid in the circulating water tank connected to the alkali washing tower is adjusted to 12, and sodium hypochlorite is added to the circulating water tank connected to the alkali washing tower to adjust the circulation The concentration of sodium hypochlorite in the treatment liquid in the water tank is 0.1%, and the alkali washing tower is turned on, and the tail gas is sprayed with the treatment liquid in the alkali washing tower. Add citric acid to the water tank to adjust the pH value of the treatment solution between 6 and 6.5, and add deodorant to the circulating water tank connected to the deodorizing tower at a rate of 100ml / h (the deodorant uses Kasong plant liquid to deodorize Odor and deodorant), open the deodorization tower, use the treatment liquid in the deodorization tower to spray the tail gas, after the treatment, open the alkal...

Embodiment 2

[0024] The tail gas produced by monensin is collected and transported to the alkali washing tower, and the pH value of the treatment liquid in the circulating water tank connected to the alkali washing tower is adjusted to 12, and sodium hypochlorite is added to the circulating water tank connected to the alkali washing tower to adjust the circulation The concentration of sodium hypochlorite in the treatment liquid in the water tank is 0.3%, and the alkali washing tower is opened, and the tail gas is sprayed with the treatment liquid in the alkali washing tower. Add citric acid to the water tank to adjust the pH value of the treatment solution between 6 and 6.5, and add deodorant to the circulating water tank connected to the deodorizing tower at a rate of 100ml / h (the deodorant uses Kasong plant liquid to deodorize Odor and deodorant), open the deodorization tower, use the treatment liquid in the deodorization tower to spray the tail gas, after the treatment, open the alkali w...

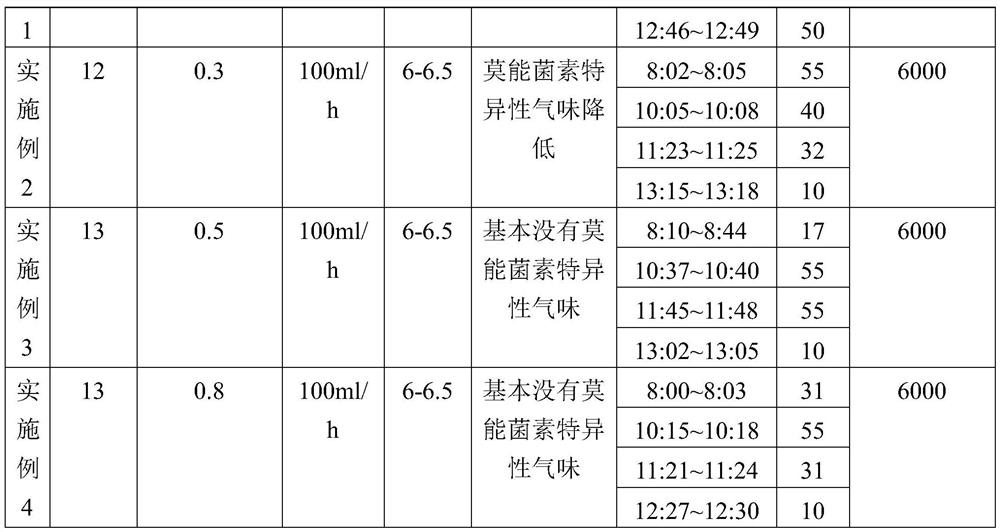

Embodiment 3

[0026] The tail gas produced by monensin is collected and transported to the alkali washing tower, and the pH value of the treatment liquid in the circulating water tank connected to the alkali washing tower is adjusted to 13, and sodium hypochlorite is added to the circulating water tank connected to the alkali washing tower to adjust the circulation The concentration of sodium hypochlorite in the treatment liquid in the water tank is 0.5%, and the alkali washing tower is opened, and the tail gas is sprayed with the treatment liquid in the alkali washing tower. Add citric acid to the water tank to adjust the pH value of the treatment solution between 6 and 6.5, and add deodorant to the circulating water tank connected to the deodorizing tower at a rate of 100ml / h (the deodorant uses Kasong plant liquid to deodorize Odor and deodorant), open the deodorization tower, use the treatment liquid in the deodorization tower to spray the tail gas, after the treatment, open the alkali w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com