A kind of preparation method of pyridine functionalized sodium alginate adsorbent

A technology of sodium alginate and adsorbent, which is applied in the field of preparation of pyridine functionalized sodium alginate adsorbent, achieving the effects of many adsorption sites, broad application prospects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

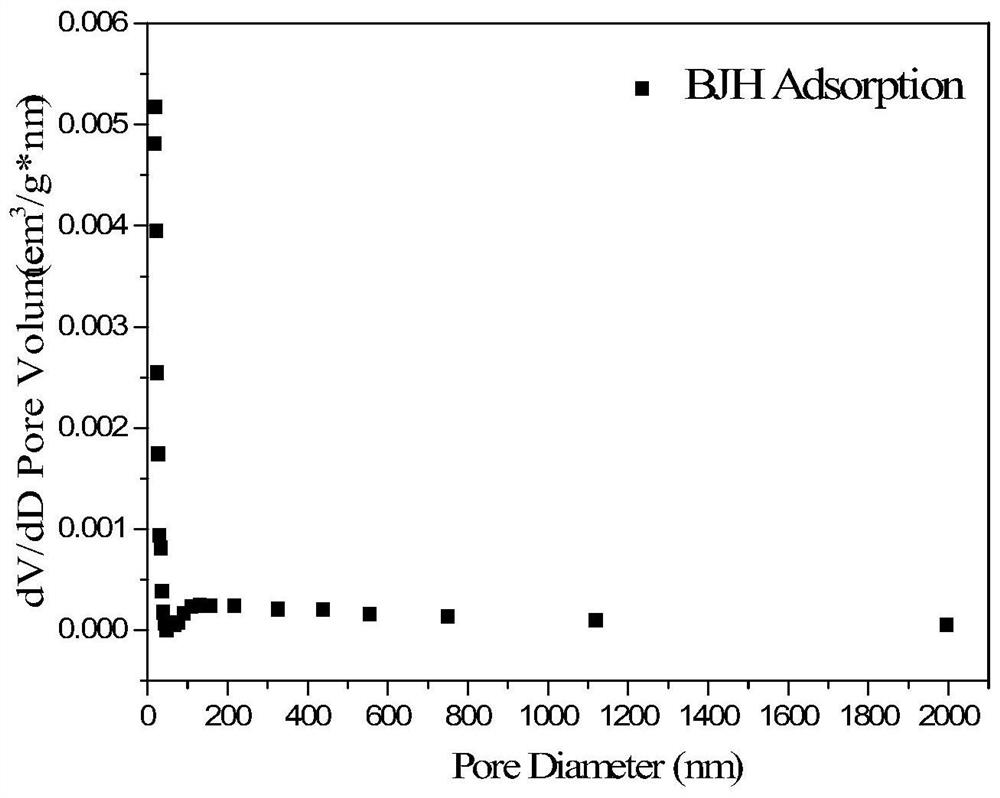

Image

Examples

Embodiment 1

[0030] The preparation method of pyridine functionalized sodium alginate adsorbent in this embodiment comprises the following steps:

[0031] S1: In a 1000mL three-neck flask, add 0.5g polyethyleneimine (M.W. 10000, 99%, Shanghai Merrill Chemical Technology Co., Ltd.), 2g sodium alginate (AR, Shanghai Merrill Chemical Technology Co., Ltd.), 500mL distilled water, Stir with a mechanical stirrer at high speed for about 1 h in an oil bath at 20°C (400r / min at a speed of 400r / min) until evenly stirred, then cool to room temperature in air to obtain a mixed mother liquor of sodium alginate and polyamine;

[0032] S2: Slowly add 1mL of epichlorohydrin to the mixed mother liquor obtained in step S1 (dropping speed is about 20d / min), stir at a speed of 300r / min during the reaction, and exchange in an oil bath at 20°C Linkage reaction 10h, obtain mixed crosslinking mother liquor;

[0033] S3: Add the mixed crosslinking mother liquor obtained in S2 dropwise into 1000mL coagulation bath...

Embodiment 2

[0038] The preparation method of pyridine functionalized sodium alginate adsorbent in this embodiment comprises the following steps:

[0039] S1: In a 1000mL three-neck flask, add 10g polyethyleneimine (M.W. 10000, 99%, Shanghai Merrill Chemical Technology Co., Ltd.), 2g sodium alginate (AR, Shanghai Merrill Chemical Technology Co., Ltd.), 500mL distilled water, in Stir at a high speed of about 1 h with a mechanical stirrer in an oil bath at 50°C (400r / min at a speed of 400r / min) until evenly stirred, then cool to room temperature in the air to obtain a mixed mother liquor of sodium alginate and polyamine;

[0040]S2: Slowly add 10mL of epichlorohydrin dropwise to the mixed mother liquor obtained in step S1 (dropping speed is about 20d / min), stir at a speed of 300r / min during the reaction, and exchange in an oil bath at 50°C Linkage reaction 4h, obtain mixed crosslinking mother liquor;

[0041] S3: Add the mixed cross-linking mother liquor obtained in S2 dropwise into 1000mL ...

Embodiment 3

[0045] The preparation method of pyridine functionalized sodium alginate adsorbent in this embodiment comprises the following steps:

[0046] S1: In a 1000mL three-necked flask, add 20g polyethyleneimine (M.W. 10000, 99%, Shanghai Merrill Chemical Technology Co., Ltd.), 10g sodium alginate (AR, Shanghai Merrill Chemical Technology Co., Ltd.), 500mL distilled water, In an oil bath at 80°C, use a mechanical stirrer to stir at high speed for about 1 h (rotation speed: 400r / min) until the stirring is uniform, and then cool to room temperature in the air to obtain a mixed mother liquor of sodium alginate and polyamine;

[0047] S2: Slowly add 25mL of epichlorohydrin dropwise to the mixed mother liquor obtained in step S1 (dropping speed is about 20d / min), stir at a speed of 300r / min during the reaction, and exchange in an oil bath at 80°C Linkage reaction 8h, obtain mixed crosslinking mother liquor;

[0048] S3: Add the mixed cross-linking mother liquor obtained in S2 dropwise int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com