Method for synthesizing pure lanthanum chromate at low temperature, lanthanum chromate synthesized by method and application of lanthanum chromate

A pure lanthanum chromate and low temperature technology, applied in the field of lanthanum chromate, can solve the problem of undiscovered pure-phase lanthanum chromate powder material, and achieve the effect of high melting point, low thermal expansion rate and good thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

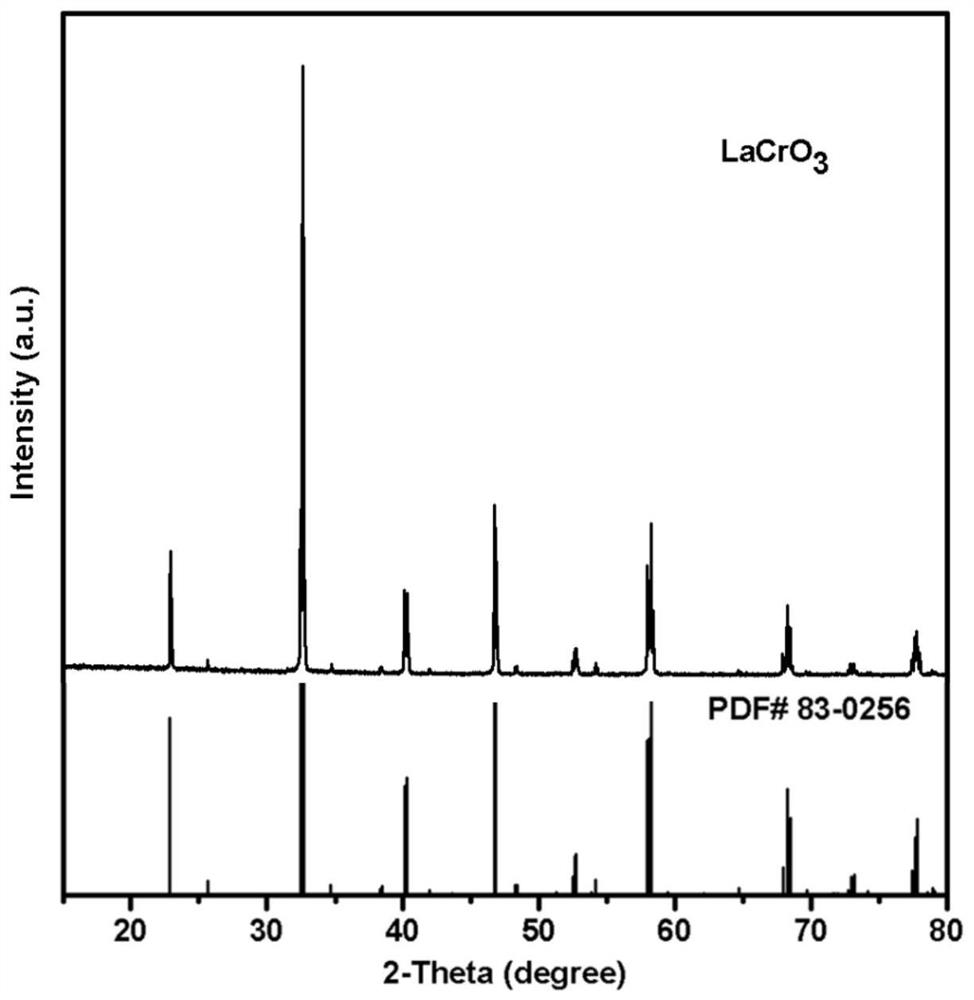

Image

Examples

Embodiment 1

[0035] a. Press LaCrO 3 The stoichiometric ratio, respectively weighed 54.379g of lanthanum oxide and 25.621g of chromium oxide, were placed in an agate mortar and mixed fully ground for 2h, to obtain a mixed powder;

[0036] b. According to the mass ratio m (NaCl) :m (KCl) =1:1.28 ratio, weigh 35.088g sodium chloride and 44.912g potassium chloride respectively, put them in an agate mortar and mix and grind them thoroughly for 2 hours to obtain mixed salt;

[0037] c. Put the mixed powder obtained in step a and the mixed salt obtained in step b in an equal mass ratio (i.e., take all the solids), place them in an agate mortar and mix and grind them thoroughly for 10 hours again to obtain a mixture;

[0038] d. Pour the mixture obtained in step c into a 300mL corundum crucible, calcinate at 600°C for 4 hours, and cool to room temperature;

[0039] e. Put the block obtained in step d into a 500mL beaker, add deionized water (the volume ratio of the block to water is about 1:2) a...

Embodiment 2

[0041] a. Press LaCrO 3 The stoichiometric ratio, respectively weighed 54.379g of lanthanum oxide and 25.621g of chromium oxide, were placed in an agate mortar and mixed fully ground for 2h, to obtain a mixed powder;

[0042] b. According to the mass ratio m (NaCl) :m (KCl) =1:1.28 ratio, weigh 35.088g sodium chloride and 44.912g potassium chloride respectively, put them in an agate mortar and mix and grind them thoroughly for 2 hours to obtain mixed salt;

[0043] c. Put the mixed powder obtained in step a and the mixed salt obtained in step b in an equal mass ratio (i.e. take all the solids), place them in an agate mortar and mix and grind again for 8 hours to obtain a mixture;

[0044] d. Pour the mixture obtained in step c into a 300 mL corundum crucible, and calcinate at 700° C. for 3 hours, and cool to room temperature.

[0045] e. Put the block obtained in step d into a 500mL beaker, add deionized water (the volume ratio of the block to water is about 1:2) and raise ...

Embodiment 3

[0047] a. Press LaCrO 3 The stoichiometric ratio, respectively weighed 54.379g of lanthanum oxide and 25.621g of chromium oxide, were placed in an agate mortar and mixed fully ground for 2h, to obtain a mixed powder;

[0048] b. According to the mass ratio m (NaCl) :m (KCl) =1:1.28 ratio, weigh 35.088g sodium chloride and 44.912g potassium chloride respectively, put them in an agate mortar and mix and grind them thoroughly for 2 hours to obtain mixed salt;

[0049] c. Put the mixed powder obtained in step a and the mixed salt obtained in step b in an equal mass ratio (i.e., take all the solids), place them in an agate mortar and mix and grind again for 6 hours to obtain a mixture;

[0050] d. Pour the mixture obtained in step c into a 300 mL corundum crucible, and calcinate at 800° C. for 3 hours, and cool to room temperature.

[0051] e. Put the block obtained in step d into a 500mL beaker, add deionized water (the volume ratio of the block to water is about 1:2) and raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com