Hydroponic culture solution for vegetables

A technology for culture liquid and vegetable water, applied in liquid fertilizer, application, organic fertilizer and other directions, can solve the problems of lack of self-purification and self-regulation, incomplete nutrient composition, and insufficient effect, and achieves significant yield increase effect and nutritional value. Comprehensive ingredients and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

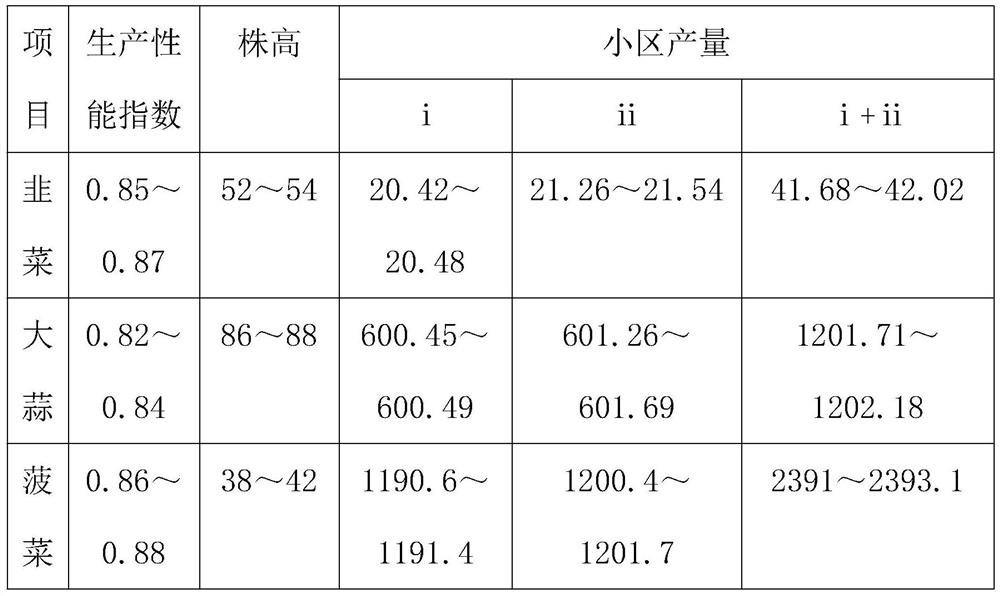

Image

Examples

Embodiment 1

[0019] A vegetable hydroponic culture solution, which is composed of the following raw materials in parts by weight: 40 parts of fermented soybean extract, 30 parts of angelica extract, 20 parts of seaweed powder, 10 parts of Bacillus thuringiensis powder, 9 parts of yeast powder, 1 part of vitamin C, 0.3 parts of nitric acid, 0.09 parts of ammonium molybdate, and 300 parts of deionized water.

[0020] The preparation method of described a kind of vegetable hydroponic culture fluid, comprises the steps:

[0021] 1) Select a certain quality of soybeans and crush them evenly in a grinder, then add 2.6 times of distilled water for soaking treatment to obtain a mixed liquid, and filter it at the same time to remove impurities, put it into a closed container, and add yeast powder to it Ferment, filter, and spray dry to obtain soybean fermented extract;

[0022] 2) Fully dissolve seaweed powder, Bacillus thuringiensis powder and deionized water, heat and stir at a speed of 60r / min ...

Embodiment 2

[0025] A vegetable hydroponic culture solution, which is composed of the following raw materials in parts by weight: 43 parts of fermented soybean extract, 32 parts of angelica extract, 23 parts of seaweed powder, 12 parts of Bacillus thuringiensis powder, 11 parts of yeast powder, 2 parts of vitamin C, 0.6 parts of nitric acid, 0.12 parts of ammonium molybdate, and 350 parts of deionized water.

[0026] The preparation method of described a kind of vegetable hydroponic culture fluid, comprises the steps:

[0027] 1) Select a certain quality of soybeans and crush them evenly in a grinder, then add 2.7 times of distilled water for soaking treatment to obtain a mixed liquid, and filter it at the same time to remove impurities, put it into a closed container, and add yeast powder to it Ferment, filter, and spray dry to obtain soybean fermented extract;

[0028] 2) Fully dissolve seaweed powder, Bacillus thuringiensis powder and deionized water, heat and stir at a speed of 65r / mi...

Embodiment 3

[0031] A vegetable hydroponic culture solution, which is composed of the following raw materials in parts by weight: 46 parts of fermented soybean extract, 34 parts of angelica extract, 26 parts of seaweed powder, 14 parts of Bacillus thuringiensis powder, 13 parts of yeast powder, 3 parts of vitamin C, 0.9 parts of nitric acid, 0.15 parts of ammonium molybdate, and 400 parts of deionized water.

[0032] The preparation method of described a kind of vegetable hydroponic culture fluid, comprises the steps:

[0033] 1) Select a certain quality of soybeans and crush them evenly in a grinder, then add 2.8 times of distilled water for soaking treatment to obtain a mixed liquid, and filter it at the same time to remove impurities, put it into an airtight container, and add yeast powder to it Ferment, filter, and spray dry to obtain soybean fermented extract;

[0034] 2) Fully dissolve seaweed powder, Bacillus thuringiensis powder and deionized water, heat and stir at a speed of 70r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com