Hydrocarbyl-terminated hyperbranched polyester and photopolymer material comprising same

A technology of hyperbranched polyester and photopolymer, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment. Reduce the storage stability of the film layer and other issues, and achieve the effects of improving storage stability, avoiding adverse effects, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Synthesis of Hydrocarbyl Terminated Hyperbranched Polyester

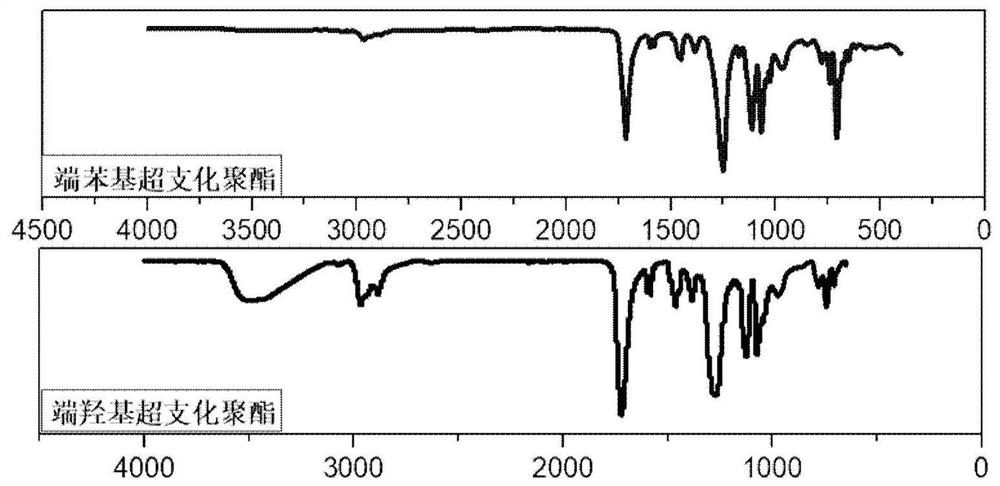

[0045] 34.5g (hydroxyl moles n 1 =0.135mol, Mw=12000) terminal hydroxyl hyperbranched polyester and 30g triethylamine are dissolved in 70gDMF, pour in the there-necked flask, stir, then slowly drip 20g benzoyl chloride (acyl chloride group mole number) with constant pressure funnel no 2 =0.14mol), the drop rate is 6mL / h. The reaction was stirred for 10 h in a cold water bath, and nitrogen was used as a protective gas. The resulting mixture was filtered twice to remove the hydrochloride of triethylamine, and the filtrate was rotated to remove the solvent at 130° C. and -0.08 MPa. The residue is washed several times with cold n-hexane to obtain the benzyl-terminated hyperbranched polyester. The reaction equation is shown in formula (3), and the infrared spectra before and after the reaction are shown in figure 1 shown. From figure 1 It can be seen that, relative to the hydroxyl-terminated hyperbranched ...

Embodiment 2

[0053] Synthesis of Hydrocarbyl Terminated Hyperbranched Polyester

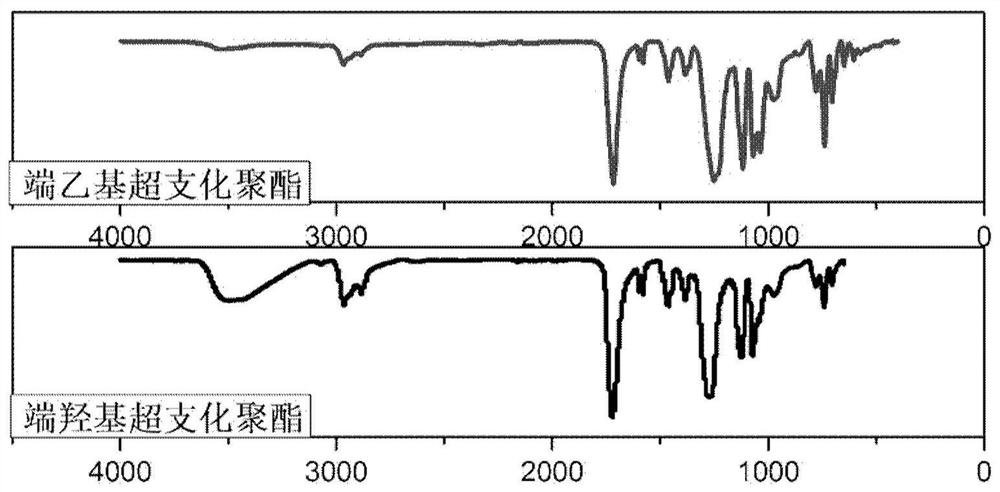

[0054] 34.5g (hydroxyl moles n 1 =0.135mol, Mw=12000) terminal hydroxyl hyperbranched polyester and 30g triethylamine are dissolved in 70gDMF, pour in the there-necked flask, stir, then slowly drip 11g acetyl chloride (acyl chloride group molar number n 2 =0.14mol), the drop rate is 6mL / h. The reaction was stirred for 10 h in a cold water bath, and nitrogen was used as a protective gas. The resulting mixture was filtered twice to remove the hydrochloride of triethylamine, and the filtrate was rotated to remove the solvent at 130° C. and -0.08 MPa. The residue is washed several times with cold n-hexane to obtain ethyl-terminated hyperbranched polyester. The reaction equation is shown in formula (4), and the infrared spectra before and after the reaction are shown in figure 2 shown.

[0055]

[0056] Preparation of photopolymer film layer

[0057] In a dark room and a safe light environment, the ph...

Embodiment 3

[0062] Synthesis of Hydrocarbyl Terminated Hyperbranched Polyester

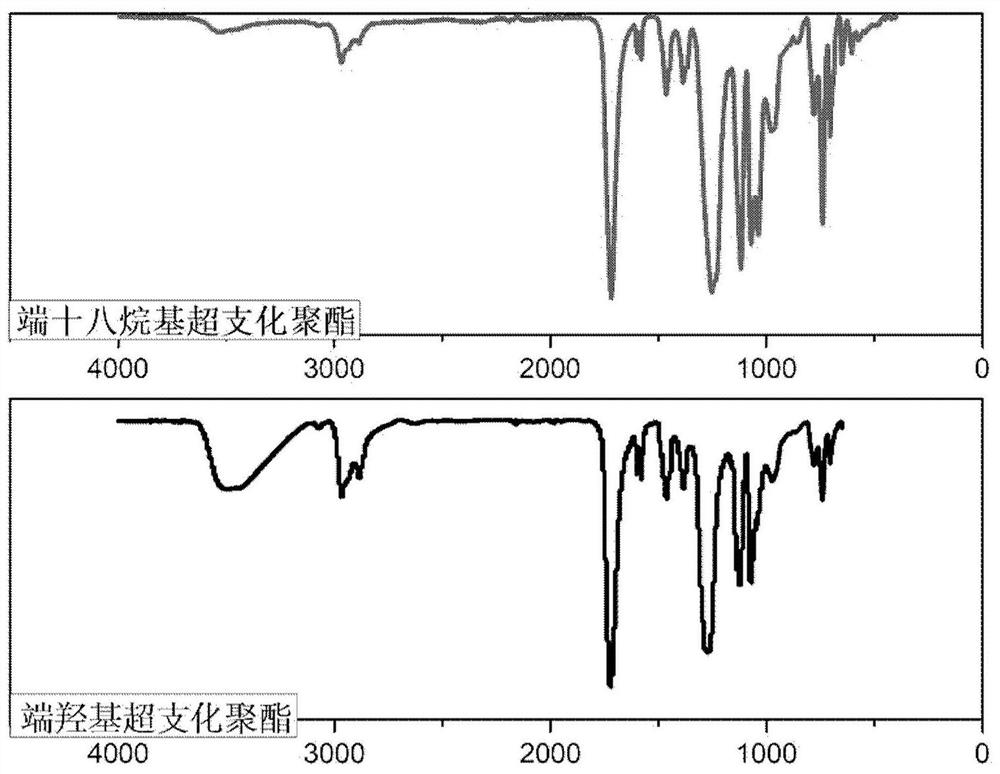

[0063] Dissolve 34.5g (hydroxyl mole number n1=0.135mol, Mw=12000) hydroxyl-terminated hyperbranched polyester and 30g triethylamine into 70gDMF, pour it into a three-necked flask, stir, and then slowly add 42.4g dropwise with a constant pressure funnel Octadecanoyl chloride (the number of moles of acid chloride groups n2=0.14mol), the dropping rate is 6mL / h. The reaction was stirred for 10 h in a cold water bath, and nitrogen was used as a protective gas. The resulting mixture was filtered twice to remove the hydrochloride of triethylamine, and the filtrate was rotated to remove the solvent at 130° C. and -0.08 MPa. The residue is washed several times with cold n-hexane to obtain octadecyl-terminated hyperbranched polyester. The reaction equation is shown in formula (5), wherein S represents alkyl CH 3 (CH 2 ) 16 -,Such as image 3 shown.

[0064]

[0065] Preparation of photopolymer film layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com