Comprehensive utilization method of phosphogypsum

A technology for phosphogypsum and gypsum agglomerates, applied in the field of phosphogypsum, can solve the problems of high production cost of sulfuric acid, excess calcium oxide, insufficient acid content, etc., and achieve the effect of low-cost comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

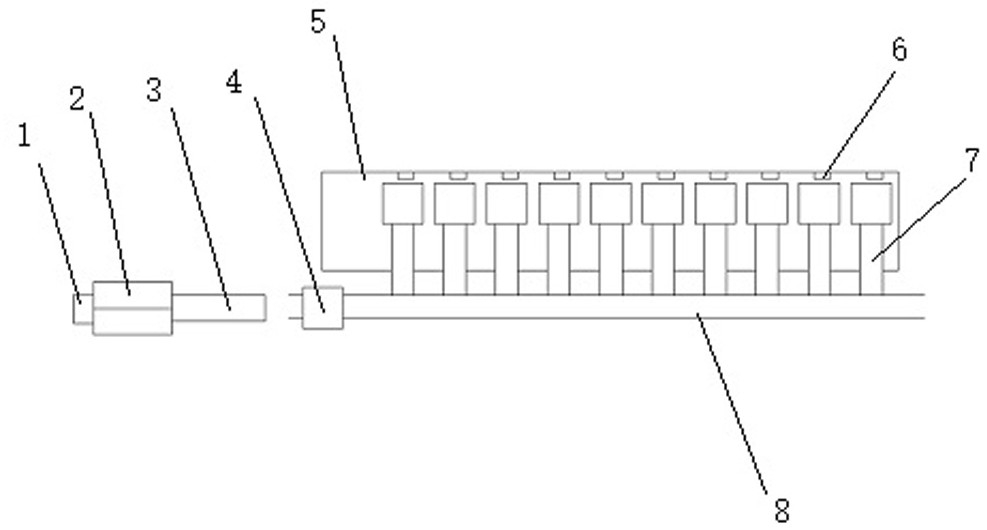

[0009] In order to better illustrate the technical solution of the present invention, the specific implementation manner of the present invention is further described in conjunction with the accompanying drawings, as figure 1 According to step 1, phosphogypsum is mixed with 10% bauxite powder and 5% coal powder, and stirred evenly. The coal powder is selected from high-sulfur coal powder, which is conducive to the maintenance of acid concentration in the flue gas. At the same time, adding an application field to high-sulfur coal, 1% sawdust or rice husk is easier to ignite; in order to further increase the acid concentration of flue gas, 0.5% sulfur is added in this example; the above materials are crushed and used with phosphogypsum The general powder stirring and mixing device in this industry is used as the phosphogypsum stirring and mixing device 1 of this example to stir evenly; according to step 2, the double-roller ball press machine commonly used in this industry is sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com