Degradable mineral fertilizer water-retaining agent and preparation method thereof

A technology of mineral fertilizers and water-retaining agents, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as difficult biodegradation, achieve mild activation conditions, short process flow, and good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

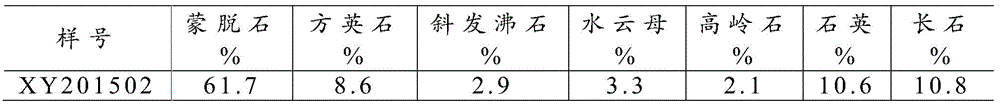

Embodiment 1

[0060] Add 15g of tapioca starch, 0.003g of N,N'-methylenebisacrylamide, and 0.003g of potassium persulfate to 300g of acrylic acid solution with a weight concentration of 10% and a neutralization degree of 100% with sodium hydroxide. gram, dissolve, and then add 24 grams of mechanically pulverized Xinyang bentonite and 24 grams of activated mica, and stir or ultrasonically disperse for 10 minutes. Stir and heat the dispersed mixed material in the reactor at 40°C for 5 hours, then raise the temperature to 30°C for 5 hours to obtain a polymer product; The method is to crush it to 0.1-2.0 mm, and finally obtain a degradable mineral fertilizer water-retaining agent (granular product).

Embodiment 2

[0062] In 300 g of acrylic acid solution with a weight concentration of 30% and a neutralization degree of 80%, add 25 g of tapioca starch, 0.09 g of N,N'-methylenebisacrylamide, and 0.09 g of potassium persulfate under stirring, dissolve, and then Add 90 grams of mechanically pulverized Xinyang bentonite and 90 grams of activated mica, and stir or ultrasonically disperse for 10 minutes. Heat the dispersed mixed material in the reactor at 90°C for 1 hour, then raise the temperature to 10°C and react for 1 hour to obtain a polymer product; the polymer product is dried at 100°C until the water content is less than 20%, and mechanically It is crushed to 0.1-2.0 mm, and finally a degradable mineral fertilizer water-retaining agent (granular product) is obtained.

Embodiment 3

[0064] Add 15g of tapioca starch, 1.5g of N,N'-methylenebisacrylamide, and 0.75g of potassium persulfate into 300g of acrylic acid solution with a weight concentration of 25% and a neutralization degree of 70% under stirring, dissolve, and then Add 15 grams of mechanically pulverized Xinyang bentonite and 15 grams of activated mica, and stir or ultrasonically disperse for 10 minutes. Heat the dispersed mixed material in the reactor at 70°C for 3 hours, then increase the temperature at 20°C for 2 hours to obtain a polymer product; dry the polymer product at 110°C until the water content is less than 20%, and use mechanical methods to It is crushed to 0.1-2.0 mm, and finally a degradable mineral fertilizer water-retaining agent (granular product) is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com