Synthesis method of DL-cysteine

A synthesis method and cysteine technology, applied in the field of DL-cysteine synthesis, can solve the problems of high toxicity and high price, and achieve the effects of reaction safety, short reaction steps and simple reaction operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

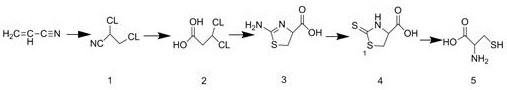

[0027] The synthetic method of embodiment 1 DL-cysteine, refer to figure 1 As shown, the details are as follows:

[0028] (1) Add 50g of acrylonitrile to a three-necked reaction flask, add catalyst magnesium carbonate, the amount of catalyst used is 10% of the weight of acrylonitrile, and slowly introduce 70g of chlorine gas below 0°C to maintain the reaction temperature between 12°C and chlorine gas After passing through, it was incubated at 12°C for 3 hours, then fed into nitrogen to drive off excess chlorine gas, and the reaction ended to obtain 114.7g of 2,3-dichloropropionitrile ( figure 1 The middle mark is 1), the yield is 98.1%, and the purity is 98.4%;

[0029] (2) Add a mixed medium of 85% acetic acid, concentrated sulfuric acid and water with a volume ratio of 1:1:1.2 to the reaction flask, then add 100 g of 2,3-dichloropropionitrile prepared in step (1), and then Reflux at 115°C for 1 hour to obtain 102.6 g of 2,3-dichloropropionic acid ( figure 1 The winning nu...

Embodiment 2

[0033] The synthetic method of embodiment 2 DL-cysteine, refer to figure 1 As shown, the details are as follows:

[0034] (1) Add 50g of acrylonitrile to a three-necked reaction flask, add catalyst magnesium carbonate, the amount of catalyst used is 12% of the weight of acrylonitrile, slowly introduce 70g of chlorine gas below 3°C, keep the reaction temperature between 17°C, chlorine gas After passing through, it was incubated at 17° C. for 4 hours, then fed into nitrogen to drive out excess chlorine, and the reaction ended to obtain 107 g of 2,3-dichloropropionitrile ( figure 1 The middle mark is 1), the yield is 92%, and the purity is 99%;

[0035] (2) Add a mixed medium of 85% acetic acid, concentrated sulfuric acid and water with a volume ratio of 1:1:1.2 to the reaction flask, then add 100 g of 2,3-dichloropropionitrile prepared in step (1), and then Reflux at 120°C for 1.2 hours to obtain 100.8 g of 2,3-dichloropropionic acid ( figure 1 The winning number is 2), the y...

Embodiment 3

[0039] The synthetic method of embodiment 3 DL-cysteine, refer to figure 1 As shown, the details are as follows:

[0040] (1) Add 50g of acrylonitrile to a three-necked reaction flask, add catalyst magnesium carbonate, the amount of catalyst used is 11% of the weight of acrylonitrile, slowly introduce 70g of chlorine gas below 0°C, and keep the reaction temperature between 14°C and chlorine gas After passing through, keep warm at 14 DEG C for 3 hours, then feed nitrogen to drive off excess chlorine, and the reaction ends to obtain 115g of 2,3-dichloropropionitrile ( figure 1 The middle mark is 1), the yield is 98.4%, and the purity is 98.9%;

[0041] (2) Add a mixed medium of 85% acetic acid, concentrated sulfuric acid and water with a volume ratio of 1:1:1.2 to the reaction flask, then add 100 g of 2,3-dichloropropionitrile prepared in step (1), and then Reflux at 118°C for 1.2 hours to obtain 104 g of 2,3-dichloropropionic acid ( figure 1 The middle mark is 2), the yield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com