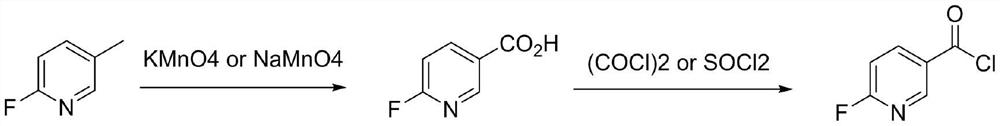

A kind of preparation method of 2-fluoro-5-formyl chloride pyridine

A technology of formyl chloride pyridine and picoline, which is applied in the field of preparation of 2-fluoro-5-formyl chloride pyridine, can solve the problems that there is no very mature process technology report, and achieve the effect of low production cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a 500mL three-necked flask, add 11.1g (0.1mol) of 2-fluoro-5-picoline, add 250mL of water, start mechanical stirring, and add 31.6g (0.2mol) of KMnO 4 and 5.6g (0.1mol) KOH, heated to 95°C in an oil bath, reacted for 5h, filtered while hot, and collected the filtrate. After the filtrate drops to normal temperature, adjust the pH value to 2-4 with concentrated hydrochloric acid, and filter if solids are precipitated; the filtrate is extracted twice with dichloroethane. The filtered solid and the extracted oil were mixed, and evaporated by rotary evaporation to obtain 11.8 g of off-white solid, which was 2-fluoro-5-carboxylic acid pyridine (melting point 275-278° C.).

[0026] Put the 2-fluoro-5-carboxylic acid pyridine obtained in the first step into a 500mL three-necked flask, add 200mL of dichloromethane, start stirring, add 16.0g of thionyl chloride dropwise, and react under reflux for 6h, distill off the solvent and excess dichloromethane Thionyl chloride. After...

Embodiment 2

[0028] In a 500mL three-necked flask, add 11.1g (0.1mol) of 2-fluoro-5-picoline, add 250mL of water, start mechanical stirring, and add 28.4g (0.2mol) of NaMnO 4 and 4.0g (0.1mol) NaOH, heated to 95°C in an oil bath, reacted for 5h, filtered while hot, and collected the filtrate. After the filtrate drops to normal temperature, adjust the pH value to 2-4 with concentrated hydrochloric acid, and filter if solids are precipitated; the filtrate is extracted twice with dichloroethane. The filtered solid and the extracted oil phase were mixed, and evaporated by rotary evaporation to obtain 11.5 g of off-white solid, which was pyridine 2-fluoro-5-carboxylate (melting point 275-278° C.).

[0029] The other steps were the same as in Example 1 to obtain 12.55 g of the colorless liquid product 2-fluoro-5-formyl chloride pyridine, which became an off-white solid after freezing, with a purity of 99.0% and a total yield of 78.7%.

Embodiment 3

[0031] In a 500mL three-necked flask, add 11.1g (0.1mol) of 2-fluoro-5-picoline, add 250mL of water, start mechanical stirring, and add 47.4g (0.3mol) of KMnO 4 and 5.6g (0.1mol) KOH, heated to 95°C in an oil bath, reacted for 5h, filtered while hot, and collected the filtrate. After the filtrate drops to normal temperature, adjust the pH value to 2-4 with concentrated hydrochloric acid, and filter if solids are precipitated; the filtrate is extracted twice with dichloroethane. The filtered solid and the extracted oil were mixed, and rotovapped to obtain 12.1 g of off-white solid, which was pyridine 2-fluoro-5-carboxylate (melting point: 275-278° C.).

[0032] Put the 2-fluoro-5-carboxylic acid pyridine obtained in the first step into a 500mL three-necked flask, add 200mL of dichloromethane, start stirring, add 16.0g of thionyl chloride dropwise, and react under reflux for 6h, distill off the solvent and excess dichloromethane Thionyl chloride. Add 85mL of n-heptane, cool an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com