Tool for vacuum heat treatment of directional/single-crystal high-temperature alloy blades and preparation process of tool

A technology of vacuum heat treatment and superalloy, applied in heat treatment equipment, heat treatment furnace, metal processing equipment, etc., can solve problems such as short circuit of heating body, conduction between blade and furnace body, damage to blade surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

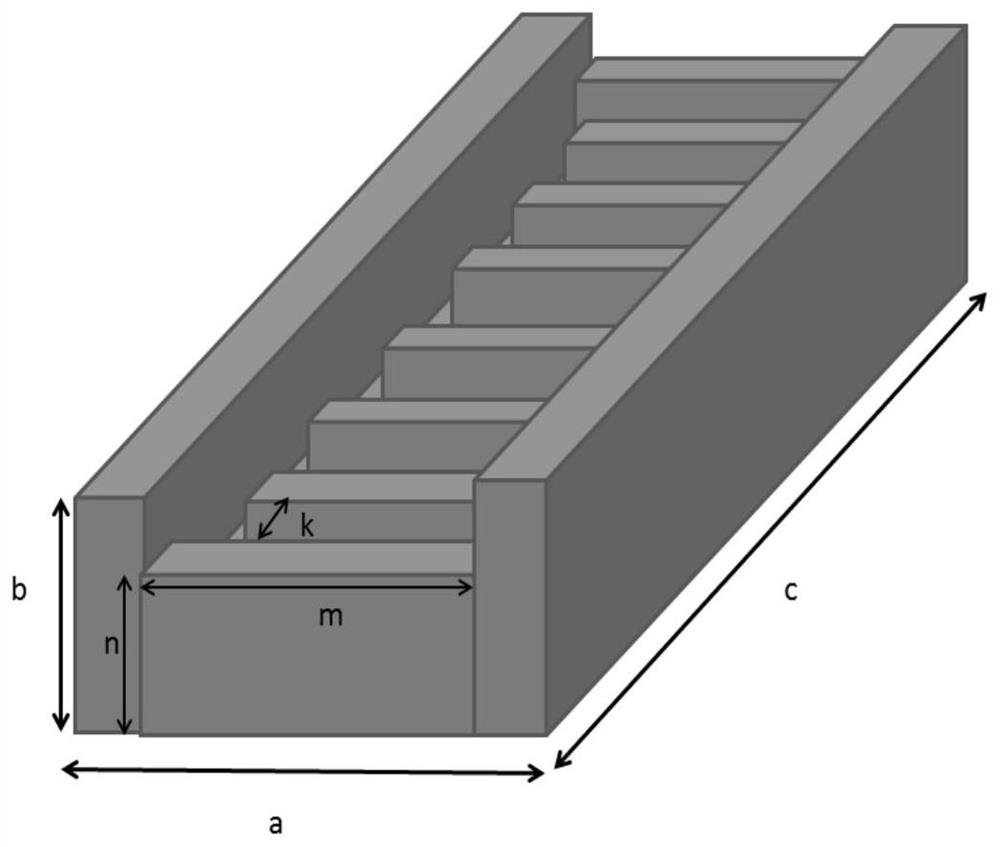

[0027] According to the outer contour size of the blade tenon, design the shape of the wax mold of the base to be similar to the blade tenon and be 5mm larger than its outer contour; make the tooling wax mold, the size is: a=100mm, b=30mm, c=250mm, m=50mm, n= 20mm, k=15mm. The wax mold is prepared by injection molding. The injection pressure of the wax mold is 0.8MPa, the injection time is 30s, and the pressure holding time is 40s. After the wax mold is prepared, the mold shell is prepared by precision casting. The coating used in the shell making process is a mixture of alumina powder and silica sol, the particle size of the powder is 300-400 mesh, the mass ratio of powder to liquid is (3.0-3.5):1, the pH value is 8-11, and the sand material is Al 2 o 3 Granules, the sand material particle size is 24-80 mesh, the drying time is 24h, and the shell thickness is 7mm. After the formwork is prepared, the sealing treatment is carried out, and the sealing treatment material is a c...

Embodiment 2

[0029] Make the tooling wax mold, the size is: a=120mm, b=30mm, c=250mm, m=50mm, n=20mm, k=30mm, the wax mold is prepared by injection molding, the wax mold injection pressure is 0.8MPa, and the injection time is 40s , The pressure holding time is 50s. After the wax pattern is prepared, the mold shell is prepared by the precision casting process. The coating used in the shell making process is a mixture of alumina powder and silica sol, the particle size of the powder is 300-400 mesh, the mass ratio of powder to liquid is (3.0-3.5):1, the pH value is 8-11, and the sand material is Al 2 o 3 Granules, the sand material particle size is 24-80 mesh, the drying time is 24h, and the shell thickness is 6mm. After the formwork is prepared, the sealing treatment is carried out, and the sealing treatment material is a coating formed by uniformly mixing alumina powder and silica sol in a weight ratio of 1:2.8. After the formwork is completely dry, grind off one end of the pre-loaded bl...

Embodiment 3

[0031] Make the tooling wax mold, the size is: a=200mm, b=30mm, c=250mm, m=50mm, n=30mm, k=30mm, the wax mold is prepared by injection molding, the wax mold injection pressure is 0.8MPa, and the injection time is 50s , The pressure holding time is 60s. After the wax pattern is prepared, the mold shell is prepared by precision casting process. The coating used in the shell making process is a mixture of alumina powder and silica sol, the particle size of the powder is 300-400 mesh, the mass ratio of powder to liquid is (3.0-3.5):1, the pH value is 8-11, and the sand material is Al 2 o 3 Granules, the sand material particle size is 24-80 mesh, the drying time is 24h, and the shell thickness is 9mm. After the formwork is prepared, the sealing treatment is carried out, and the sealing treatment material is a coating formed by uniformly mixing alumina powder and silica sol in a weight ratio of 1:2.8. After the formwork is completely dry, grind off one end of the pre-loaded blade ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com