Anti-corrosion stainless steel pipe for ship

A stainless steel pipe, anti-corrosion technology, applied in the direction of coating, furnace type, furnace, etc., can solve the problems of unsatisfactory corrosion resistance and prone to corrosion, improve corrosion resistance and oxidation resistance, and prevent intergranular corrosion , Improving the effect of high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

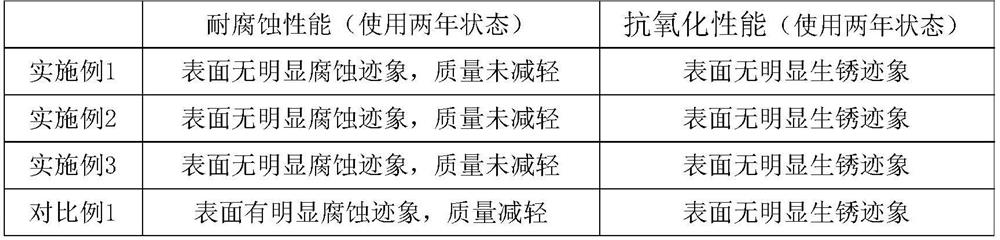

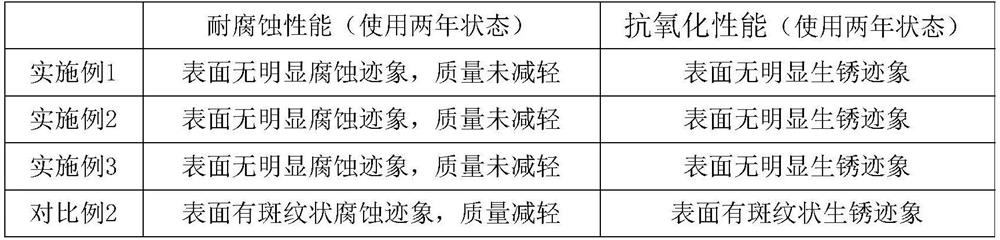

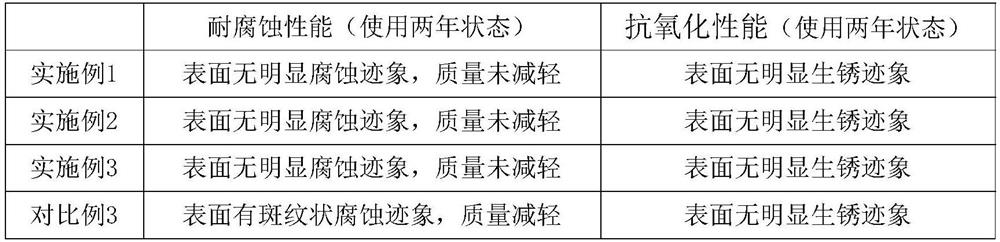

Examples

Embodiment 1

[0042] The present embodiment provides a kind of anti-corrosion marine stainless steel pipe, including anti-corrosion stainless steel pipe and the anti-corrosion coating applied on the surface of anti-corrosion stainless steel pipe, by mass percentage, anti-corrosion stainless steel pipe includes the following elements:

[0043] Chromium Cr: 14%;

[0044] Nickel Ni: 10%;

[0045] Titanium Ti: 0.1%;

[0046] Niobium Nb: 0.1%;

[0047] Molybdenum Mo: 1.5%;

[0048] Silicon Si: 0.8%;

[0049] Carbon C: 0.03%;

[0050] Sulfur S: 0.015%;

[0051] Nitrogen N: 0.01%.

[0052] The balance is Fe and other unavoidable impurities, and the sum of the mass percentages of the above-mentioned elements is 100%.

[0053] In this embodiment, the anti-corrosion coating adopts one of alcohol-soluble phenolic resin, modified phenolic resin, pure phenolic resin or polyurea elastic coating.

[0054] A preparation method of the anti-corrosion marine stainless steel pipe as described above, co...

Embodiment 2

[0072] The present embodiment provides a kind of anti-corrosion marine stainless steel pipe, including anti-corrosion stainless steel pipe and the anti-corrosion coating applied on the surface of anti-corrosion stainless steel pipe, by mass percentage, anti-corrosion stainless steel pipe includes the following elements:

[0073] Chromium Cr: 17%;

[0074] Nickel Ni: 15%;

[0075] Titanium Ti: 0.2%;

[0076] Niobium Nb: 0.2%;

[0077] Molybdenum Mo: 3.0%;

[0078] Silicon Si: 0.9%;

[0079] Carbon C: 0.05%;

[0080] Sulfur S: 0.025%;

[0081] Nitrogen N: 0.15%.

[0082] The balance is Fe and other unavoidable impurities, and the sum of the mass percentages of the above-mentioned elements is 100%.

[0083] In this embodiment, the anti-corrosion coating adopts one of alcohol-soluble phenolic resin, modified phenolic resin, pure phenolic resin or polyurea elastic coating.

[0084] A preparation method of the anti-corrosion marine stainless steel pipe as described above, co...

Embodiment 3

[0102] The present embodiment provides a kind of anti-corrosion marine stainless steel pipe, including anti-corrosion stainless steel pipe and the anti-corrosion coating applied on the surface of anti-corrosion stainless steel pipe, by mass percentage, anti-corrosion stainless steel pipe includes the following elements:

[0103] Chromium Cr: 20%;

[0104] Nickel Ni: 20%;

[0105] Titanium Ti: 0.3%;

[0106] Niobium Nb: 0.3%;

[0107] Molybdenum Mo: 4.0%;

[0108] Silicon Si: 1.0%;

[0109] Carbon C: 0.08%;

[0110] Sulfur S: 0.04%;

[0111] Nitrogen N: 0.3%.

[0112] The balance is Fe and other unavoidable impurities, and the sum of the mass percentages of the above-mentioned elements is 100%.

[0113] In this embodiment, the anti-corrosion coating adopts one of alcohol-soluble phenolic resin, modified phenolic resin, pure phenolic resin or polyurea elastic coating.

[0114] A preparation method of the anti-corrosion marine stainless steel pipe as described above, comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com