Preparation method and application of immobilized photocatalyst PVDF-TiO2@g-C3N4 fiber pad

A technology of photocatalyst and fiber mat, applied in the field of photocatalysis, can solve the problems of photocatalytic performance to be improved, inability to effectively control heterojunction, complex preparation method, etc., achieve excellent photocatalytic activity, easy separation and recycling, preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of PVDF-TiO 2 @g-C 3 N 4 Fiber pad:

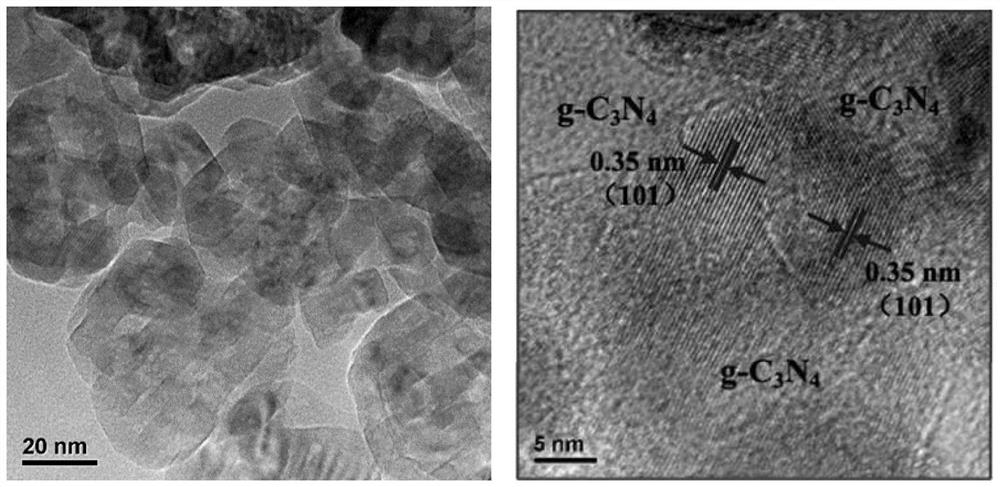

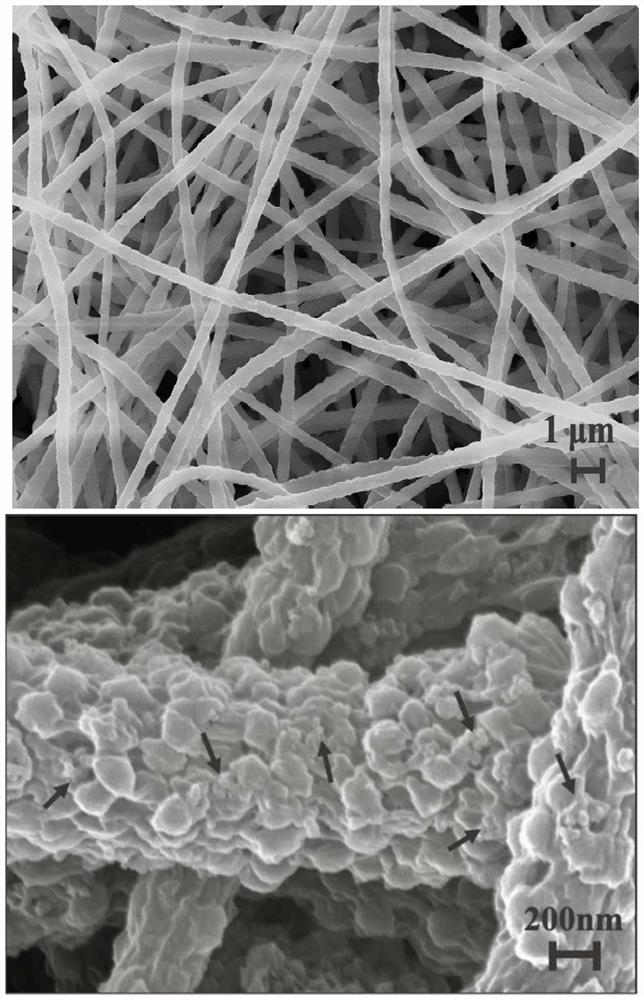

[0031] (1) Dissolve 10g of urea in 10mL of deionized water, then add 1g of anatase titanium dioxide, vacuumize to -0.08MPa and stir to obtain a uniform solution. After centrifugation and water washing, vacuum dry at 60°C for 12h, and grind to obtain a catalyst precursor body, the catalyst precursor was calcined at 520°C under nitrogen atmosphere for 2h to obtain the following figure 1 TiO shown 2 @g-C 3 N 4 catalyst;

[0032] (2) Add 0.2g TiO 2 @g-C 3 N 4 Catalyst, polyvinylidene fluoride and polyvinylpyrrolidone with a mass fraction ratio of 8%:2% were dissolved in 5mL N-N dimethylacetamide and 5mL acetone solution, stirred at 60°C and cooled to room temperature, followed by ultrasonication to obtain the precursor body solution;

[0033] (3) The precursor solution is passed through an electrospinning process. The electrospinning process conditions are that the DC voltage is 15kV, the flow rate of the syringe ...

Embodiment 2

[0037] Preparation of PVDF-TiO 2 @g-C 3 N 4 Fiber pad:

[0038] (1) Dissolve 8g of urea in 10mL of deionized water, then add 1g of anatase titanium dioxide, vacuumize to -0.08MPa and stir to obtain a uniform solution. After centrifugation and water washing, vacuum-dry at 60°C for 12h, and grind to obtain a catalyst precursor body, the catalyst precursor was calcined at 520°C under nitrogen atmosphere for 2h to obtain TiO 2 @g-C 3 N 4 catalyst;

[0039] (2) Add 0.2g TiO 2 @g-C 3 N 4 Catalyst, polyvinylidene fluoride and polyvinylpyrrolidone with a mass fraction ratio of 8%:2% were dissolved in 5mL N-N dimethylacetamide and 5mL acetone solution, stirred at 60°C and cooled to room temperature, followed by ultrasonication to obtain the precursor body solution;

[0040] (3) The precursor solution is passed through an electrospinning process, and the electrospinning process conditions are a DC voltage of 15kV, a syringe pump flow rate of 1.5mL / h, a receiving distance of 15...

Embodiment 3

[0044] Preparation of PVDF-TiO 2 @g-C 3 N 4 Fiber pad:

[0045] (1) Dissolve 12g of urea in 10mL of deionized water, then add 1g of anatase titanium dioxide, vacuumize to -0.08MPa and stir to obtain a uniform solution. After centrifugation and water washing, vacuum-dry at 60°C for 12h, and grind to obtain a catalyst precursor body, the catalyst precursor was calcined at 520°C under nitrogen atmosphere for 2h to obtain TiO 2 @g-C 3 N 4 catalyst;

[0046] (2) Add 0.2g TiO 2 @g-C 3 N 4 Catalyst, polyvinylidene fluoride and polyvinylpyrrolidone with a mass fraction ratio of 10%:2% were dissolved in 5mL N-N dimethylacetamide and 5mL acetone solution, stirred at 60°C and cooled to room temperature, followed by ultrasonication to obtain the precursor body solution;

[0047] (3) The precursor solution is passed through an electrospinning process. The electrospinning process conditions are that the DC voltage is 20kV, the flow rate of the syringe pump is 2mL / h, the receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com