Preparation method of isometric crystal nano tungsten carbide powder

A technology of nano-tungsten carbide and equiaxed crystals, which is applied in the direction of carbide, nanotechnology, tungsten/molybdenum carbide, etc., can solve the problems of being unable to meet environmental protection and safety, and achieve the smallest size difference, particle size reduction, and energy saving The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

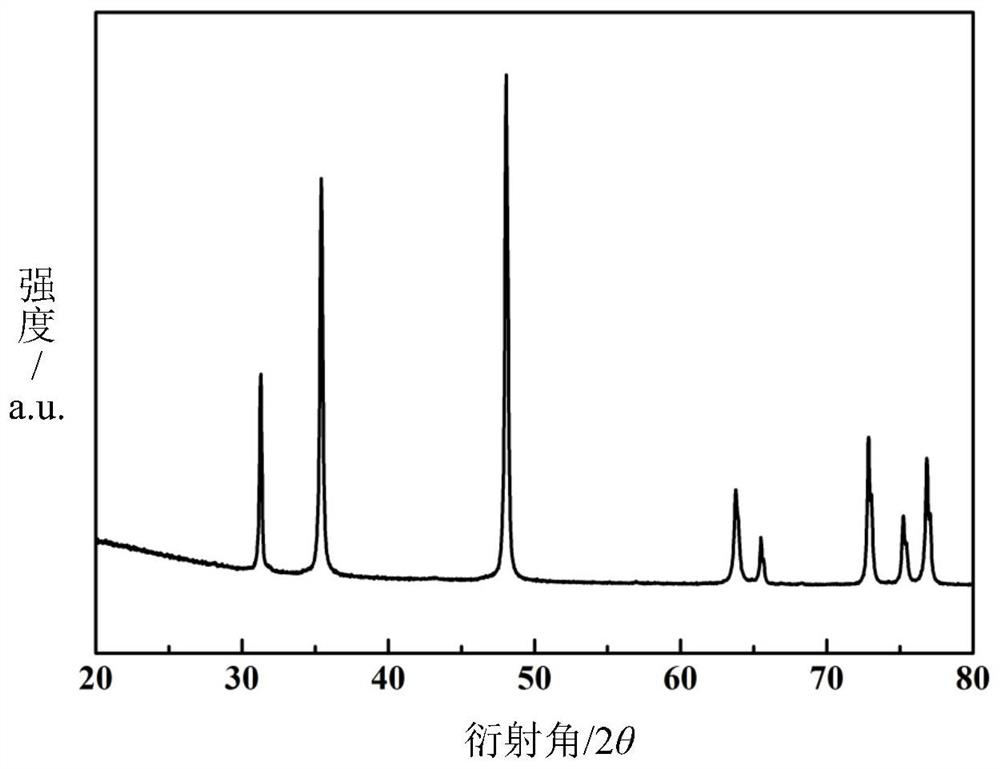

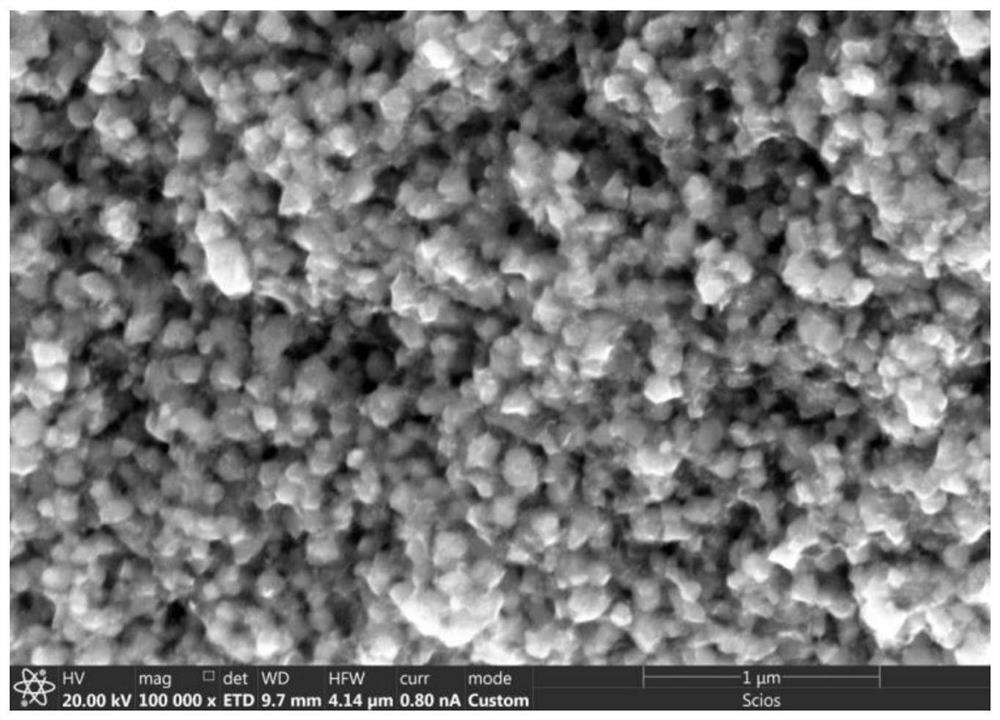

[0041] As an example, this paper also specifically provides a green preparation method of equiaxed crystal nano-tungsten carbide powder, including the following steps:

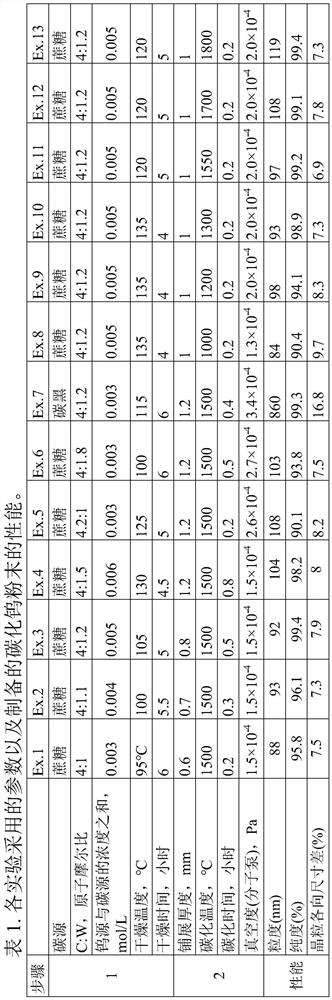

[0042] (1) Weigh ammonium metatungstate and edible carbon source powders such as caramel, fructose, sucrose and soluble starch according to the molar ratio of 1:0.5~1.6, and prepare a solution with a concentration of 0.003~0.009 moles per liter with deionized water, Then place it in a plate-type heat-collecting magnetic stirring device and dry it at 85-135°C for 4-10 hours to obtain a colloidal precursor;

[0043] (2) Spread the colloidal precursor evenly on the inner wall of the corundum boat with a thickness of 0.5-1.2 mm, and finally put it into a high-vacuum graphite-lined tube furnace to complete the integrated treatment of cracking and reaction. The reaction temperature and time are 1300 ~1500℃ and 0.2~0.8 hours, the vacuum degree is (1.3~3.4)×10 -4 Pa, the final equiaxed crystal nano-tungsten carbide p...

Embodiment

[0046] The content disclosed in the present invention is described more specifically through the following examples. These examples are for illustrative purposes only. Embodiments of the present invention are not limited to these specific examples. All parts, percentages and ratios reported in the following examples are by weight unless otherwise stated. Moreover, all reagents used in the examples were commercially available and used without further treatment. Those skilled in the art can easily purchase or prepare the starting materials used in the examples. Unless otherwise specified, materials used in the examples were of analytical grade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com