Rubber material for sealing rubber strip

A technology of rubber material and sealing strip, applied in the field of sealing strip, can solve the problems of poor processing performance, difficult to add operating oil, etc., and achieve the effect of good anti-aging performance, wide protection range, and avoiding unpleasant smell of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

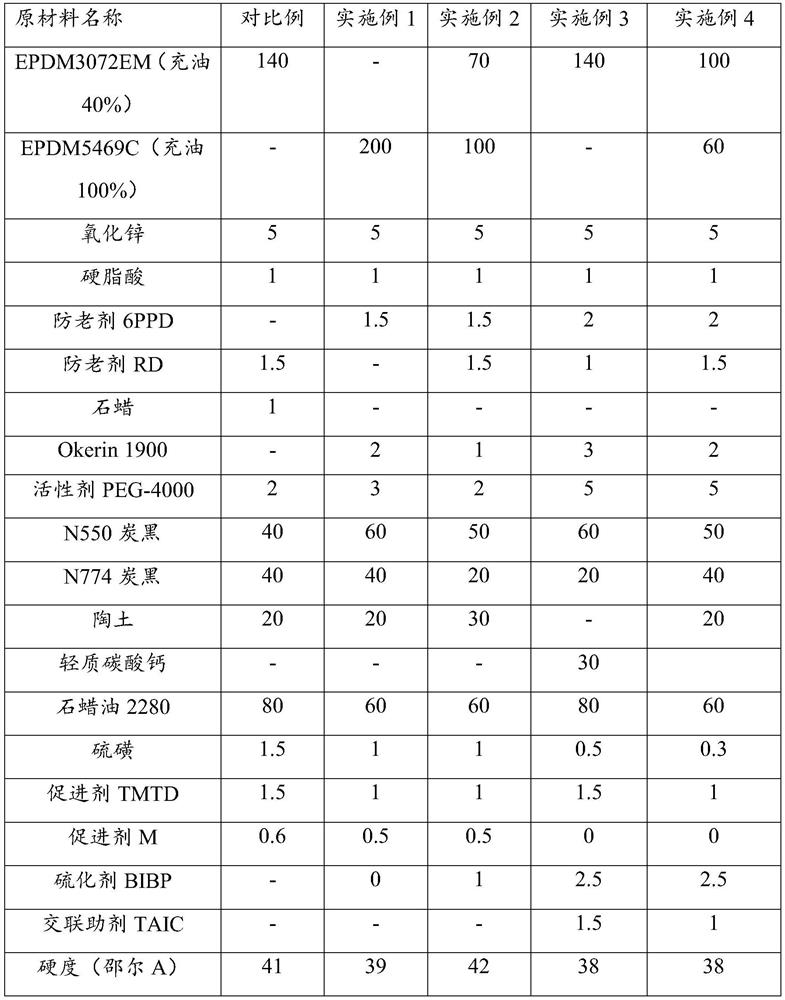

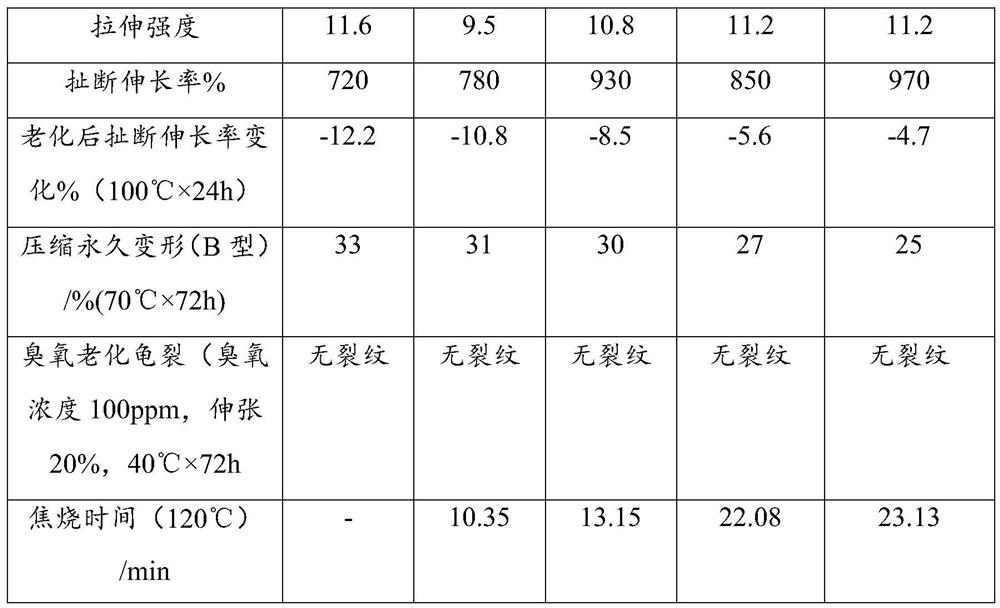

Examples

preparation example Construction

[0045] The present invention also provides a preparation method of the rubber material for the sealing strip described in the above technical solution, comprising the following steps:

[0046] mixing oil-extended EPDM rubber, zinc oxide, stearic acid, anti-aging agent, protective wax, active agent, reinforcing filler and paraffin oil for the first mixing to obtain a masterbatch;

[0047] The masterbatch and the vulcanizing agent are mixed for the second kneading to obtain the rubber material for the sealing strip.

[0048] In the present invention, when the raw material of the rubber material for the sealing strip contains an accelerator, the accelerator is preferably added during the second kneading.

[0049] In the present invention, the first kneading and the second kneading are preferably performed in an internal mixer. In the present invention, there is no special limitation on the specific parameters of the first mixing and the second mixing, and methods known to those ...

Embodiment 1

[0054] A kind of rubber material for sealing strips in this embodiment, its raw material comprises the following components by weight:

[0055] 200 parts of EPDM5469C, 5 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of antioxidant 6PPD, 2 parts of protective wax Okerin1900, 3 parts of active agent PEG-4000, 60 parts of N550 carbon black, 40 parts of N774 carbon black, 20 parts of clay , 60 parts of paraffin oil, 1 part of sulfur, 1 part of accelerator TMTD, and 0.5 parts of accelerator M.

[0056] The preparation method adopts the two-stage mixing method of GK250 internal mixer, including the following steps:

[0057] Step 1, masterbatch mixing: set the mixer speed to 50rpm, add oil-filled EPDM rubber into the mixer, and add zinc oxide, stearic acid, protective wax Okerin 1900, and anti-aging agent 6PPD after mixing for 20 seconds , active agent PEG-4000 and pottery clay, after mixing for 50s, add N550 carbon black and N774 carbon black, add paraffin oil after mixing...

Embodiment 2

[0060] A kind of rubber material for sealing strips in this embodiment, its raw material comprises the following components by weight:

[0061] 70 parts of EPDM3072EM, 100 parts of EPDM5469C, 5 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of antioxidant RD, 1.5 parts of antioxidant 6PPD, 1 part of protective wax Okerin 1900, 2 parts of active agent PEG-4000, 50 parts of N550 carbon black parts, 20 parts of N774 carbon black, 30 parts of clay, 60 parts of paraffin oil, 1 part of sulfur, 1.2 parts of accelerator TMTD, 0.5 parts of accelerator M and 1 part of vulcanizing agent BIBP.

[0062] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com