Extractant composition and resource utilization method of iron-containing wastewater

An extraction agent and composition technology, which is applied to the resource utilization of iron-containing wastewater and the field of extraction agent composition, can solve the problem that the organic amine extraction agent is expensive, the waste water resource utilization cost is high, and the extraction system has weak iron extraction ability. problem, to achieve the effect of low cost, large saturated capacity, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

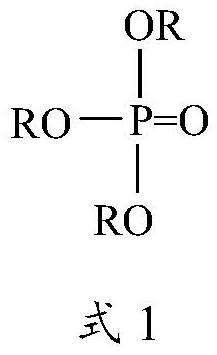

Method used

Image

Examples

Embodiment 1

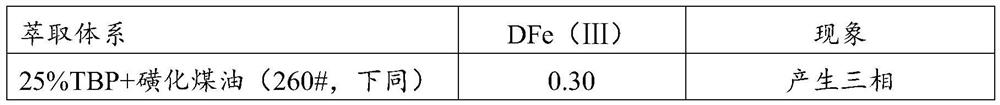

[0030] The extract contains Fe 3+ 102.61g / L, Al 3+ 12.81g / L, hydrochloric acid 3.7mol / L, the extraction system used is shown in Table 1. The extraction process conditions are: O / A=2 / 1, the extraction time is 5 minutes, and the extraction temperature is 25°C.

[0031] Table 1 Extraction results of different extraction systems

[0032]

[0033]

[0034] The results in Table 1 show that when "25% TBP + 35% 2-octanol + sulfonated kerosene" is used as the extraction system, the iron distribution ratio is 0.98, which is greater than that of "25% TBP + sulfonated kerosene" and "35% 2-octanol + sulfonated kerosene". The sum of the distribution ratios of iron when "kerosene" is used as the extraction system is 0.59, indicating that TBP and 2-octanol have a synergistic extraction effect, and 2-octanol is also beneficial to eliminate the formed three phases. Therefore, in the extraction system of "25% TBP + 35% 2-octanol + sulfonated kerosene", 2-octanol is both a co-extractant ...

Embodiment 2

[0036] The extract contains Fe 3+ 76.24g / L, Al 3+ 13.56g / L, hydrochloric acid 3.3mol / L, the extraction system used is phosphoric acid ester TBP by mass ratio: secondary octanol: sulfonated kerosene=6:7:7 (that is 30% TBP+35% secondary octanol+35% sulfonated kerosene), extraction ratio O / A (organic phase / water phase)=3 / 1, extraction temperature is room temperature, extraction time is 4min, six-stage countercurrent extraction.

[0037] Table 2 Six-stage countercurrent cascade extraction data table

[0038]

[0039] The iron extraction residue is returned to the fly ash for leaching aluminum with hydrochloric acid.

[0040] Take the loaded organic phase after the above extraction and carry out back-extraction. Compared with O / A=3.5 / 1 in back-extraction, the back-extraction agent is pH=1 acidified water (0.1mol / L hydrochloric acid solution), back-extraction at room temperature, and the time for back-extraction for 5min, six-stage countercurrent back extraction.

[0041] Tab...

Embodiment 3

[0047] The extract contains Fe 3+ 127.98g / L, Al 3+ 11.36g / L, hydrochloric acid 3.5mol / L, the extraction system used is phosphoric acid ester TBP by mass ratio: secondary octanol: sulfonated kerosene=1:2:2 (that is 20% TBP+40% secondary octanol+40% sulfonated kerosene), extraction ratio O / A=3.5 / 1, extraction temperature is room temperature, extraction time is 4min, five-stage countercurrent extraction.

[0048] Table 4 five-stage countercurrent cascade extraction data table

[0049]

[0050] The iron extraction residue is returned to the fly ash for leaching aluminum with hydrochloric acid.

[0051] Take the loaded organic phase after the above extraction for back extraction, the back extraction ratio is O / A=3 / 1, the back extraction agent is acidified water with pH=1, back extraction at room temperature, the back extraction time is 5min, six-stage countercurrent back extraction .

[0052] Table 5 Six-stage countercurrent cascade stripping data table

[0053]

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com