Fireproof flame-retardant cable and preparation method thereof

A fire-resistant and flame-retardant cable technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of unstable dispersion of inorganic flame retardants, great influence on cable mechanical properties, and reduced flame-retardant performance of cables, so as to reduce the phenomenon of agglomeration , reduce deformation, improve the effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

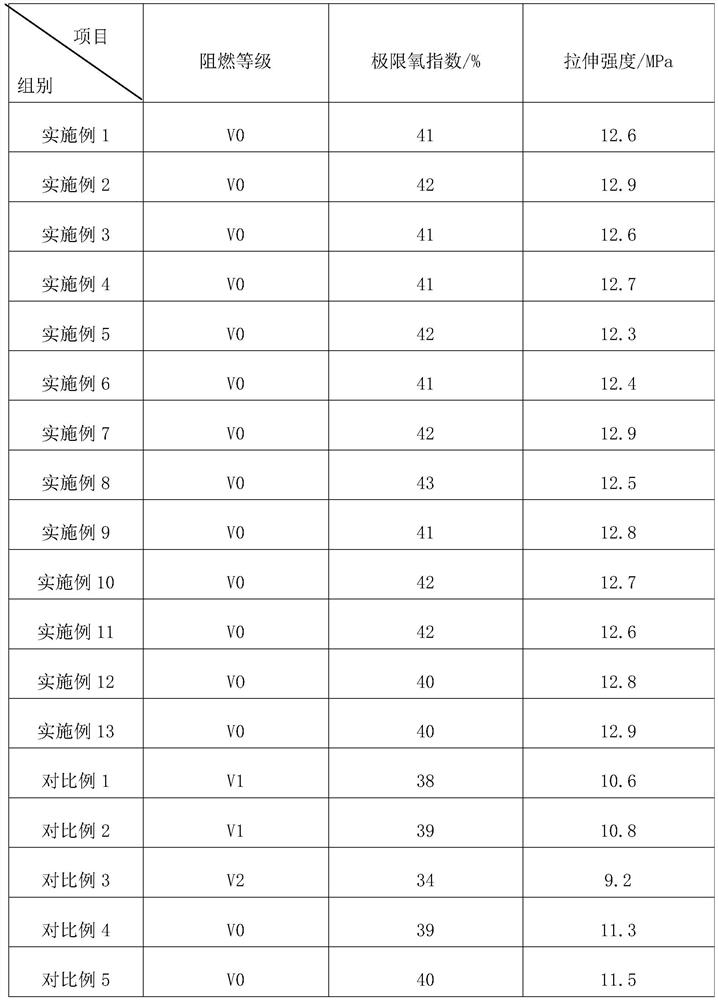

Examples

Embodiment 1

[0046] Example 1: A fire-resistant and flame-retardant cable, the components and their corresponding parts by weight are shown in Table 1, and were prepared through the following steps:

[0047] S1, put polyvinyl chloride resin, resorcinol bis(diphenyl phosphate), modified nano-silicon dioxide, and aluminum hydroxide powder into a mixer, and mix uniformly for 5 minutes at a speed of 300 rpm to obtain a mixture A;

[0048] S2, add antioxidant, compatibilizer, lubricant to mixture A, continue mixing at 300rpm rotating speed for 5min, obtain mixture B;

[0049] S3, put the compound B into the twin-screw extruder and extrude and granulate to obtain the cable material. The temperature of each section of the twin-screw extruder is set at 160°C, 160°C, 165°C, 175°C, 180°C, 180°C , 180°C, the screw speed is set at 200rpm;

[0050] S4, the cable material is melted and extruded, coated on the surface of the wire, cooled and solidified to obtain a fire-resistant and flame-retardant cabl...

Embodiment 2-6

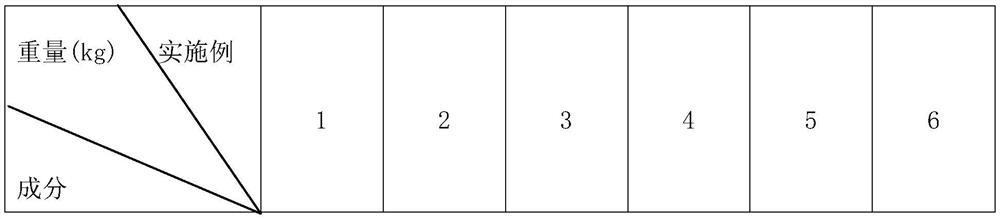

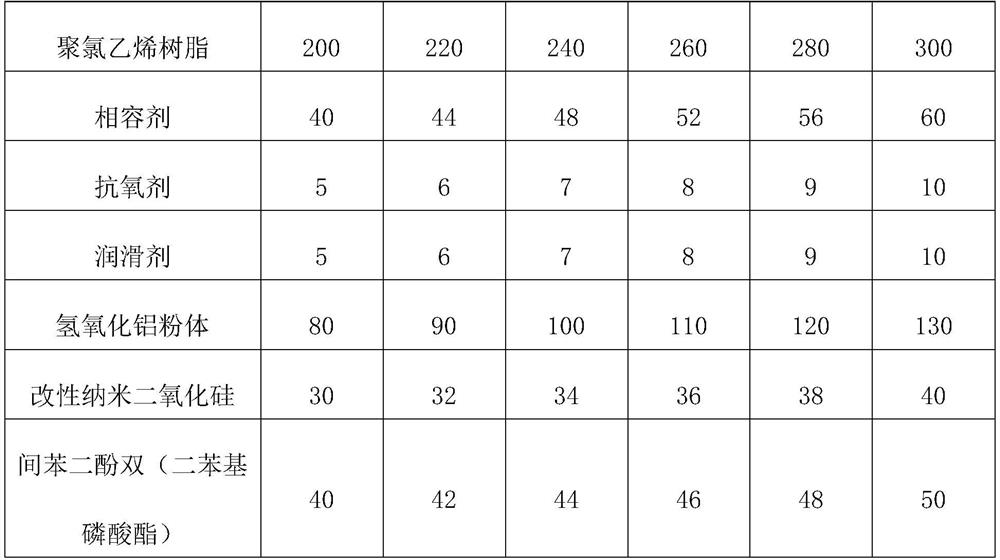

[0056] Embodiment 2-6: A fire-resistant and flame-retardant cable. The difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0057] Each component and its weight (kg) in table 1 embodiment 1-6

[0058]

[0059]

Embodiment 7

[0060] Embodiment 7: A fire-resistant and flame-retardant cable. The difference from Embodiment 1 is that it also includes 20 kg of melamine cyanurate. In S1, melamine cyanurate and polyvinyl chloride resin, resorcinol bis( Diphenyl phosphate), modified nano-silicon dioxide, and aluminum hydroxide powder are added together in a mixer and stirred to obtain a mixture A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com