Structure and heat energy recovery system of fluidized bed gasifier

A fluidized bed gasification furnace, heat recovery technology, applied in the gasification process, granular/powdered fuel gasification, chemical industry, etc., can solve the problem of high cost of refractory layer construction and material costs, easy cracks in the refractory layer, Problems such as shedding, slag discharge channel and overheating of the outer wall of the equipment can be solved, and the effect of improving fly ash, reducing equipment investment and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

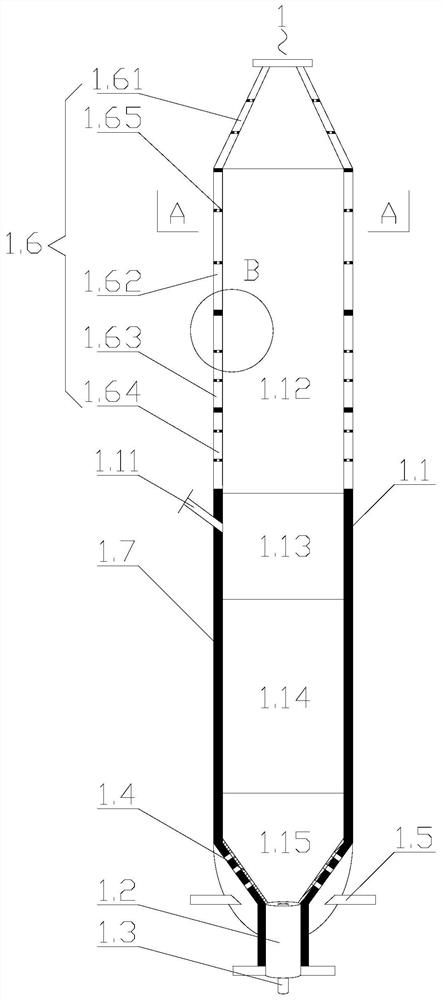

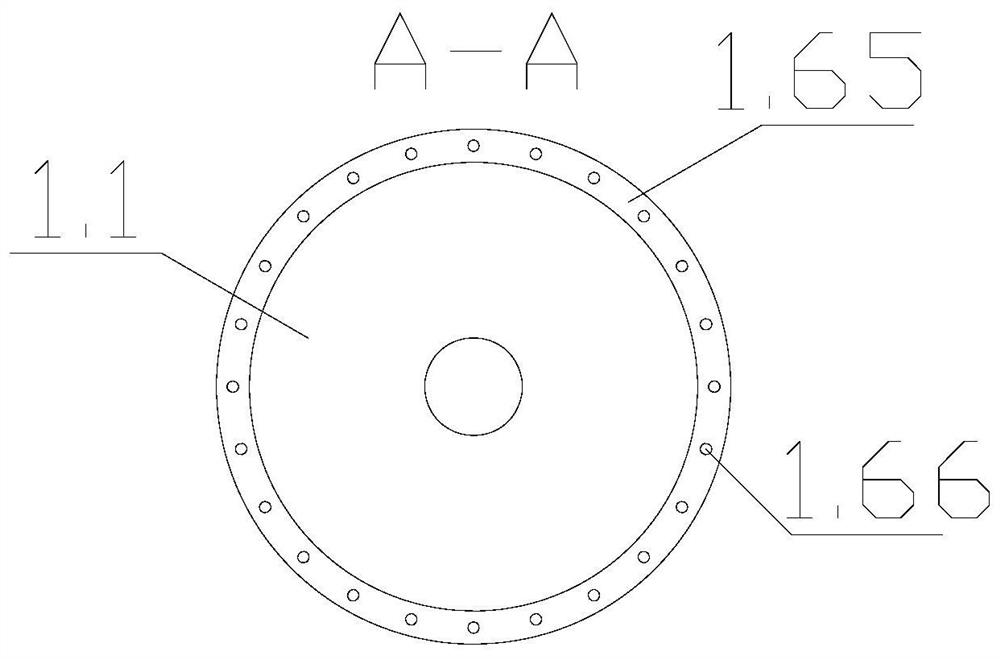

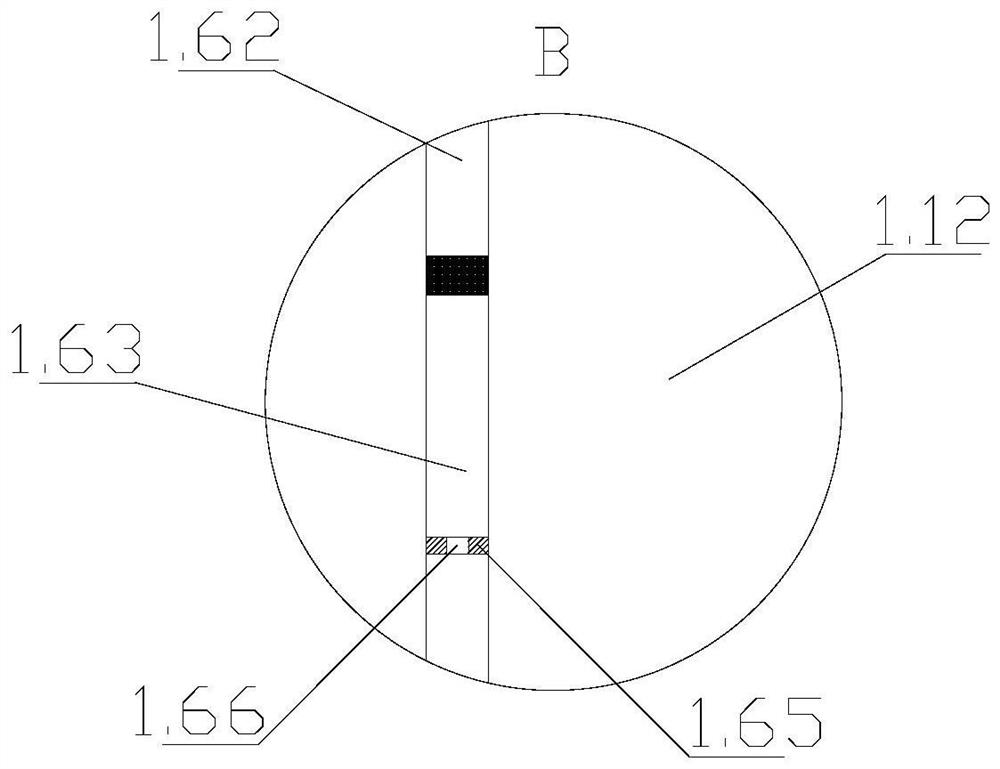

[0024] Embodiment 1: as Figure 1-3 As shown, the structure of a fluidized bed gasification furnace includes a furnace body 1.1, a gas outlet is opened on the top of the furnace body 1.1; a coal inlet 1.11 is opened on the side wall of the furnace body 1.1; A slag discharge channel 1.2 is arranged at the bottom, and a central pipe 1.3 is arranged in the slag discharge channel 1.2; a gas distribution plate 1.4 is fixedly arranged between the slag discharge channel 1.2 and the inner wall of the furnace body 1.1; the furnace body 1.1 below the gas distribution plate 1.4 The side wall is connected with an air inlet pipe 1.5; the furnace body 1.1 is divided into a heat exchange zone 1.12, a dry distillation zone 1.13, a gasification reduction zone 1.14 and a high temperature oxidation zone 1.15 in order from top to bottom, so that the gasification furnace 1 appears The temperature gradient is more conducive to the generation of methane gas, and the content of methane is more than 1...

Embodiment 2

[0026] Embodiment 2: as Figure 4-5 As shown, the embodiment of the present invention further provides a heat recovery system for a fluidized bed gasifier, which includes the above gasifier 1, a water source 2, a steam drum 3, a gas storage tank 4 and a desuperheater 5; a water source 2 It is connected with the water inlet of jacket A1.61 through a pipeline; the water outlet of jacket A1.61 and jacket B1.62 is connected with the water inlet of steam drum 3; the water outlet of steam drum 3 is connected with the inlet of jacket B1.62 The water port is connected; the air outlet of the steam drum 3 is connected with the air inlet of the jacket C1.63; It communicates with the air inlet of jacket D1.64; the air outlet of jacket D1.64 communicates with the air inlet of gas storage cabinet 4 through pipelines; the gas outlet of gas storage cabinet 4 communicates with the air inlet pipe 1.5 of gasifier 1 .

[0027] A first temperature sensor 6 is set at the gas outlet of the gasifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com