Novel process for separating silver-zinc-bismuth materials

A new process and material technology, applied in the new process field of silver zinc bismuth material separation, can solve problems such as increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

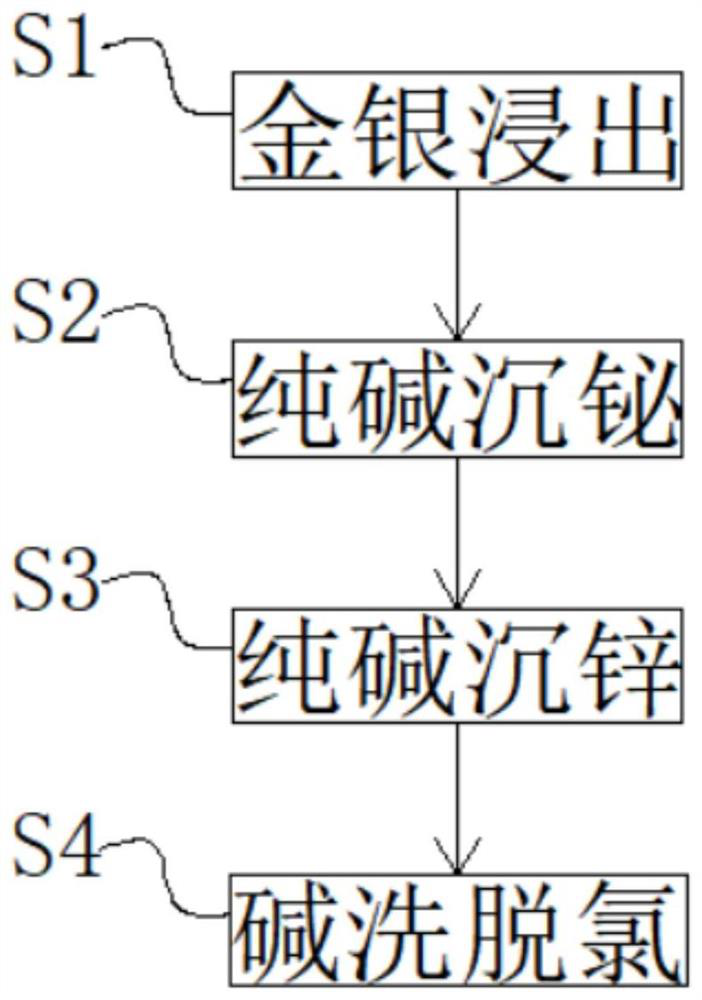

[0020] see figure 1 , the present invention provides a kind of technical scheme: a kind of novel process of silver-zinc-bismuth material separation, comprises the following steps:

[0021] S1. Gold and silver leaching: Raymond machine grinds silver-zinc slag into silver-zinc slag powder, and mixes silver-zinc slag powder with sodium chlorate to prepare mixture A. Then, put the above-mentioned mixture A into hydrochloric acid to make zinc generate Zinc chloride and bismuth produce bismuth chloride and dissolve in water, while silver precipitates to achieve the separation of bismuth, zinc and silver. Silver precipitation, react for 1 hour, then add flocculant, static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com