A magnetic recyclable coni-mofs@gr adsorbent and its preparation method and its application to the adsorption of organic dyes

A technology of organic dyes and adsorbents, applied in the direction of selective adsorption, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low efficiency and high cost of wastewater treatment, achieve high thermal stability, enhanced chemical stability, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

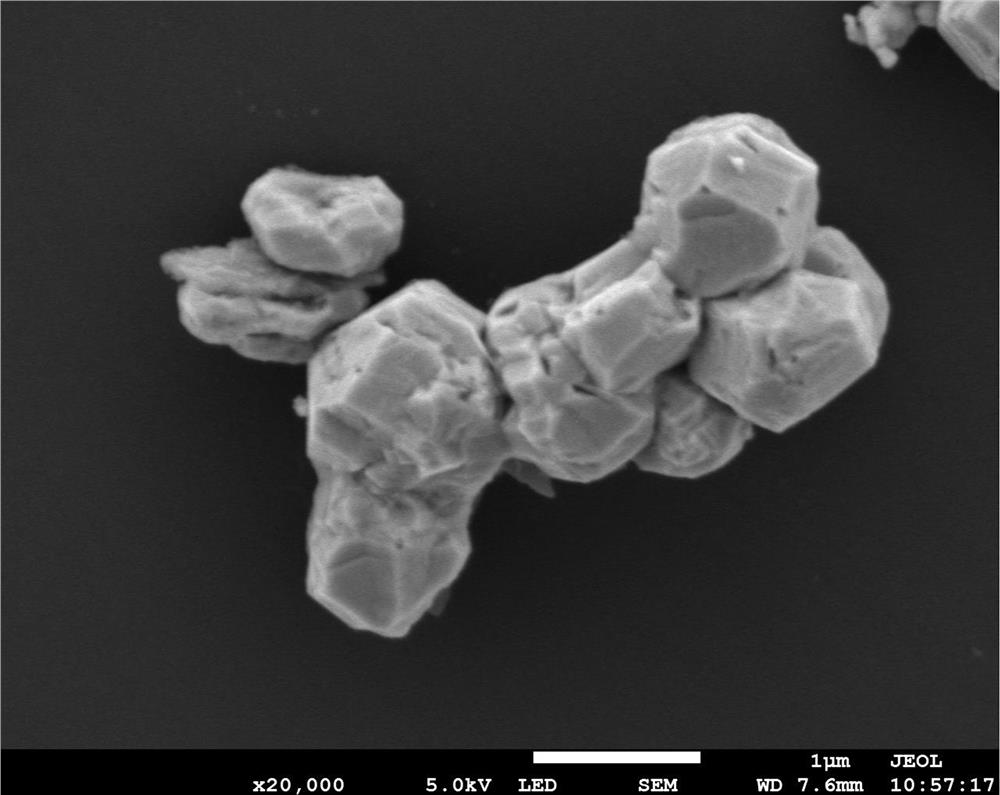

[0024] Example 1: 0.275 mmol of Co(NO 3 ) 2 , 0.275 mmol of Ni(NO 3 ) 2 and 0.65 mmol of 2-aminoterephthalic acid were added to 36 mL of solvent (30 mL of N.N-dimethylformamide, 3 mL of ethanol and 3 mL of secondary water) for sonication. The resulting product was sealed in a reactor and heated at 160 °C for 20 h. Then the reactor was cooled to room temperature, and the solid was collected and washed several times with secondary water. Finally, the obtained solid was dried overnight at 60 °C to obtain magnetic CoNi-MOFs powder.

[0025] Add 3.0 mg / mL graphene and 5 mg / mL CoNi-MOFs to water, and ultrasonicate at 40 KHz for 20 min to form a uniform dispersion. Vacuum drying at 60 °C yielded CoNi-MOFs@GR adsorbent.

Embodiment 2

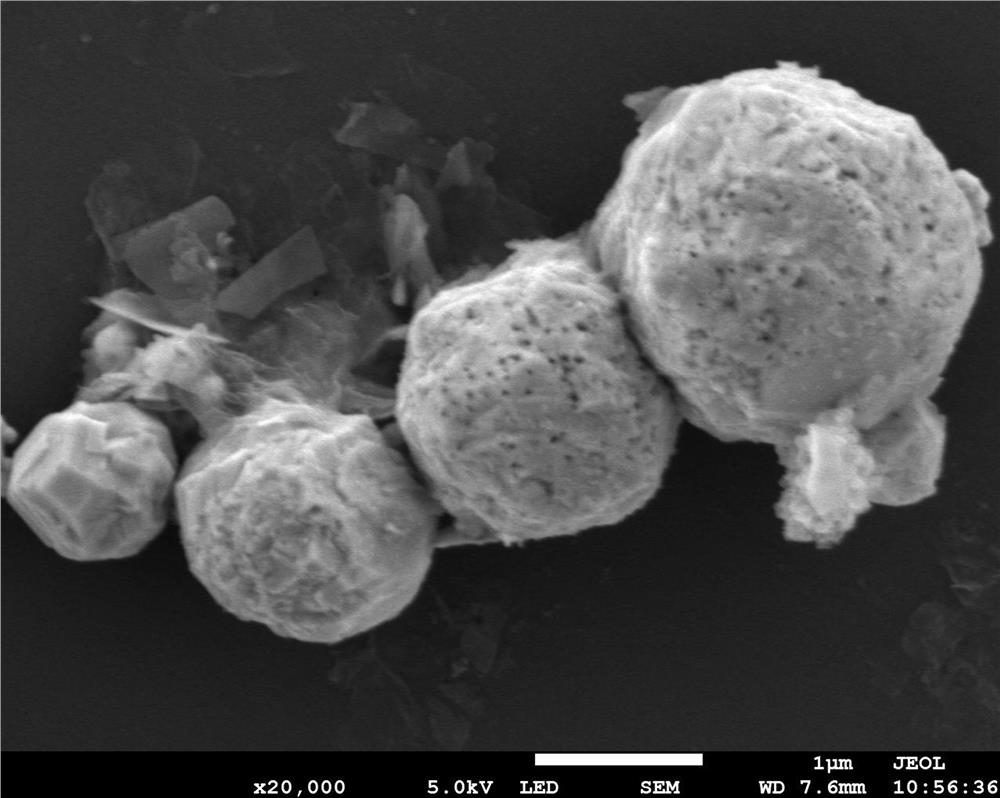

[0026] Example 2: 0.375 mmol of Co(NO 3 ) 2 , 0.375 mmol of Ni(NO 3 ) 2 and 0.75 mmol of 2-aminoterephthalic acid were added to 36 mL of solvent (32 mL of N.N-dimethylformamide, 2 mL of ethanol and 2 mL of secondary water) for sonication. The resulting product was sealed in a reactor and heated at 200 °C for 24 h. Then the reactor was cooled to room temperature, and the solid was collected and washed several times with secondary water. Finally, the obtained solid was dried overnight at 60 °C to obtain magnetic CoNi-MOFs powder.

[0027] 5.0 mg / mL graphene and 8 mg / mL CoNi-MOFs were added to water, and ultrasonicated at 40 KHz for 30 min to form a uniform dispersion. Vacuum drying at 60 °C yielded CoNi-MOFs@GR adsorbent.

Embodiment 3

[0028] Embodiment 3: the Co(NO of 0.475 mmol 3 ) 2 , 0.475 mmol of Ni(NO 3 ) 2and 0.85 mmol of 2-aminoterephthalic acid were added to 36 mL of solvent (33 mL of N.N-dimethylformamide, 1.5 mL of ethanol and 1.5 mL of secondary water) for sonication. The resulting product was sealed in a reactor and heated at 220 °C for 28 h. Then the reactor was cooled to room temperature, and the solid was collected and washed several times with secondary water. Finally, the obtained solid was dried overnight at 60 °C to obtain magnetic CoNi-MOFs powder.

[0029] Add 8.0 mg / mL graphene and 10 mg / mL CoNi-MOFs to water, and ultrasonicate at 40 KHz for 40 min to form a uniform dispersion. Vacuum drying at 60 °C yielded CoNi-MOFs@GR adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

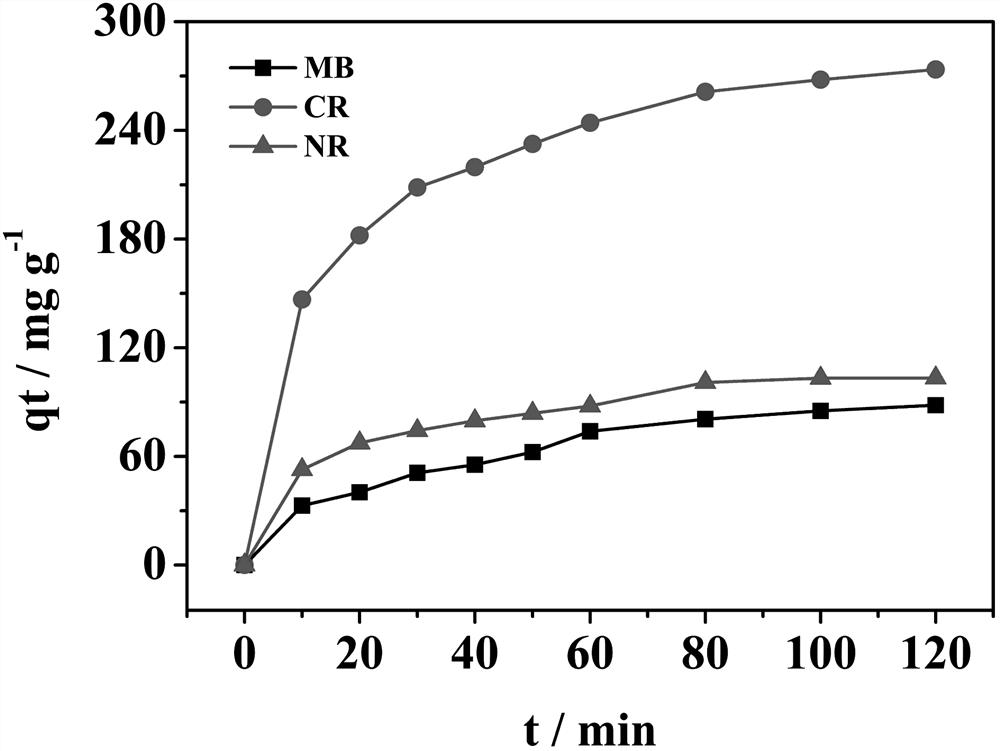

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com