Layered mineral and iron polysulfide intercalation composite material and method and application thereof

A technology of layered minerals and polysulfides, applied in chemical instruments and methods, iron sulfide, physical/chemical process catalysts, etc., can solve problems such as low catalytic effect and failure to meet industrial requirements, so as to increase catalytic performance and improve The effect of catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of above-mentioned composite material is as follows:

[0033] S1: Put the iron salt in a volatile organic solvent and stir until the iron salt is completely dissolved to obtain an iron salt compound solution. Wherein, the volatile organic solvent can be one of methanol, ethanol, propanol, isopropanol and ethylene glycol, and the iron salt can be ferric chloride, ferrous sulfate, ferrous chloride, ferric fluoride and ferric phosphate kind of.

[0034] S2: Put the reducing agent in deionized water and stir until the reducing agent is completely dissolved to obtain a reducing agent solution. Wherein, the reducing agent can be one of thiourea, sodium thiosulfate, sodium sulfide, sodium disulfide and ammonium sulfide.

[0035] S3: Wash the layered minerals with water, then filter or centrifugally dehydrate, repeat the washing several times to remove the surface impurities of the layered minerals, then dry at 60-80°C, cool to room temperature, and obt...

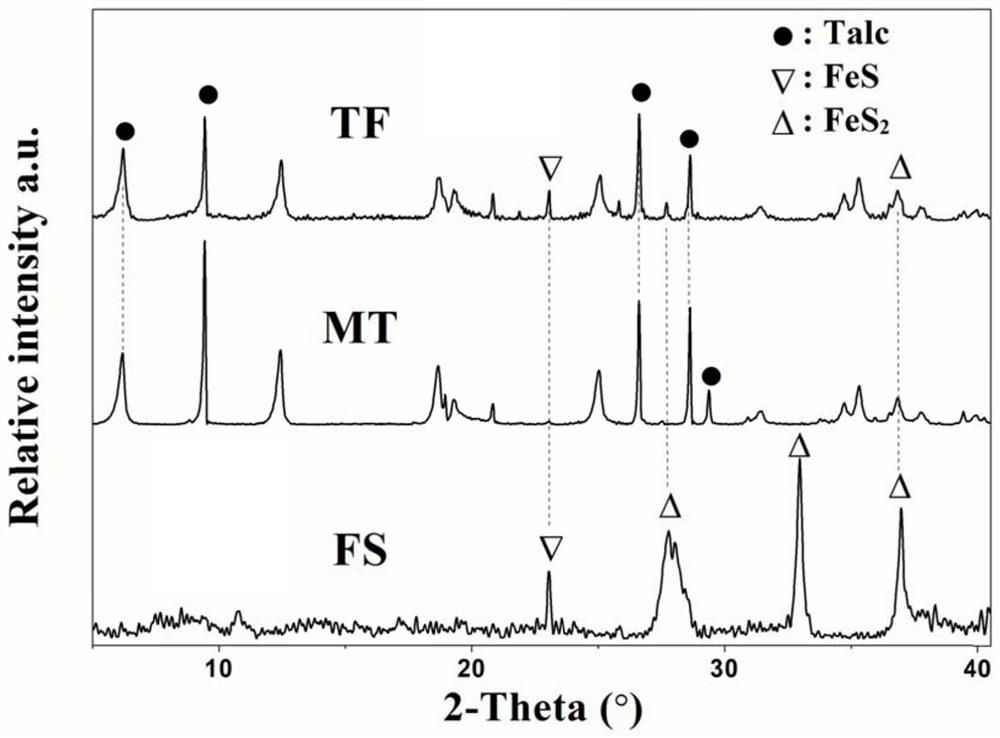

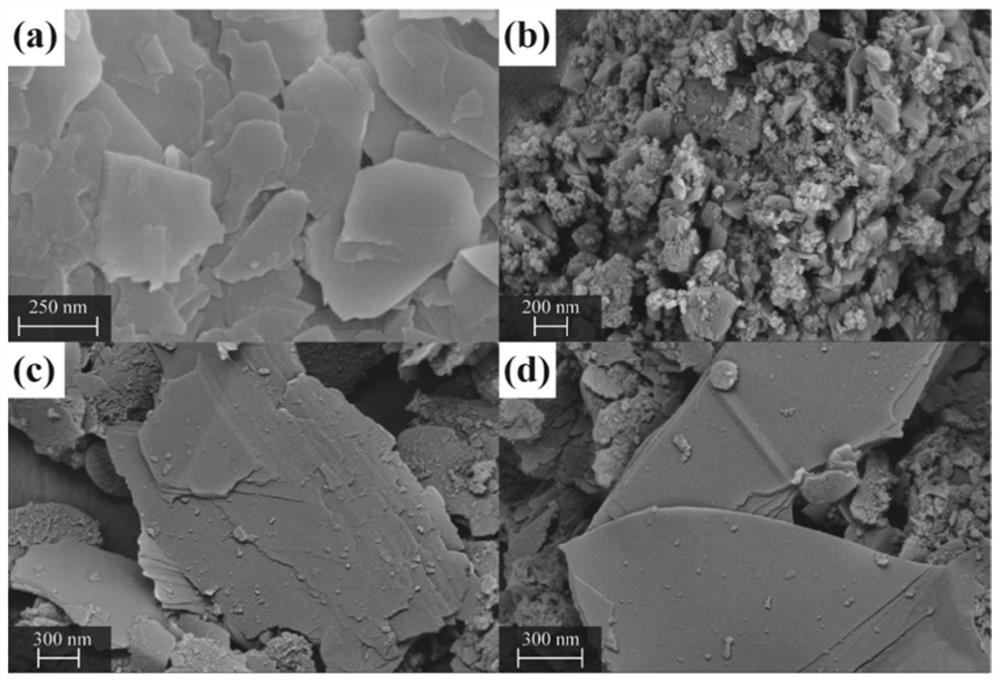

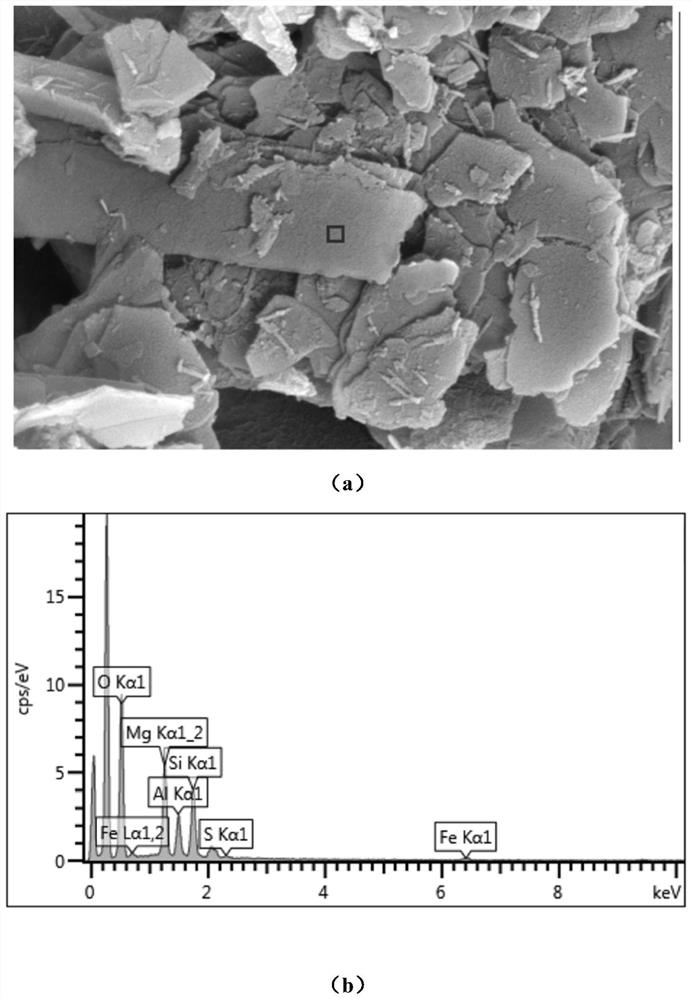

Embodiment 1

[0043] S1: Put ferric chloride hexahydrate in absolute ethanol and stir until the ferric chloride hexahydrate is completely dissolved to obtain a ferric chloride solution.

[0044] S2: Sodium sulfide is placed in deionized water, and stirred until the sodium sulfide is completely dissolved to obtain a sodium sulfide solution.

[0045] S3: Take talc that is 3 times the weight of ferric chloride hexahydrate in S1, clean the surface impurities of the talc, dry it at 60° C., and cool it to room temperature to obtain a talc sample.

[0046] S4: Mix the talc sample with the ferric chloride solution, wherein the mixing weight ratio of talc and ferric chloride is 1:0.2. After stirring evenly, grind in a grinder for 1-2 hours to obtain mixture A.

[0047] S5: Mix mixture A with sodium sulfide solution, wherein the weight ratio of sodium sulfide to ferric chloride hexahydrate is 1:0.5. After stirring evenly, grind in a grinder for 3-4 hours to obtain mixture B.

[0048] S6: Put the m...

Embodiment 2

[0052] S1: Anhydrous ferric chloride is placed in absolute ethanol, and stirred until the anhydrous ferric chloride is completely dissolved to obtain a ferric chloride solution.

[0053] S2: Sodium thiosulfate is placed in deionized water, and stirred until the sodium thiosulfate is completely dissolved to obtain a sodium thiosulfate solution.

[0054] S3: Take talc that is 3 times the weight of anhydrous ferric chloride in S1, clean the surface impurities of the talc, dry it at 60° C., and cool it to room temperature to obtain a talc sample.

[0055] S4: Mix the talc sample with the ferric chloride solution, wherein the mixing weight ratio of talc and ferric chloride is 1:0.2. After stirring evenly, grind in a grinder for 1-2 hours to obtain mixture A.

[0056] S5: Mix mixture A with sodium thiosulfate solution, wherein the weight ratio of sodium thiosulfate to anhydrous ferric chloride is 1:1. After stirring evenly, grind in a grinder for 3-4 hours to obtain mixture B.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com