Olefinic carbon heat conduction film applied to 5G terminal

A technology of olefinic carbon heat conduction film and heat conduction film, which is applied in applications, modification through conduction heat transfer, household appliances, etc., can solve the problems of not being able to meet 5G, poor heat conduction and heat dissipation performance of heat conduction film, and inability to isolate electromagnetic interference, etc., to achieve reduction Effects of contact thermal resistance, improving thermal diffusivity and thermal conductivity, and improving overall heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

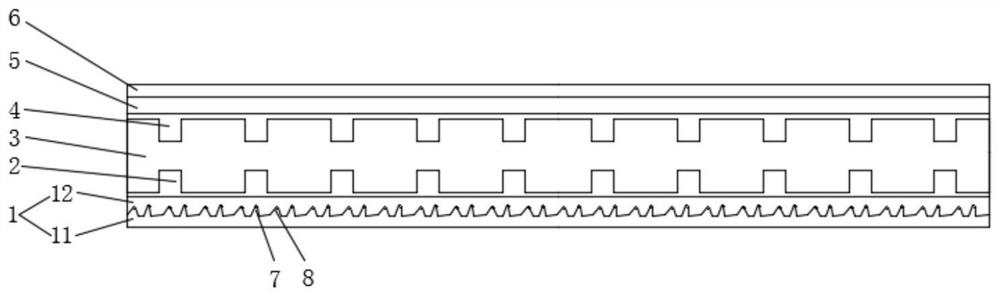

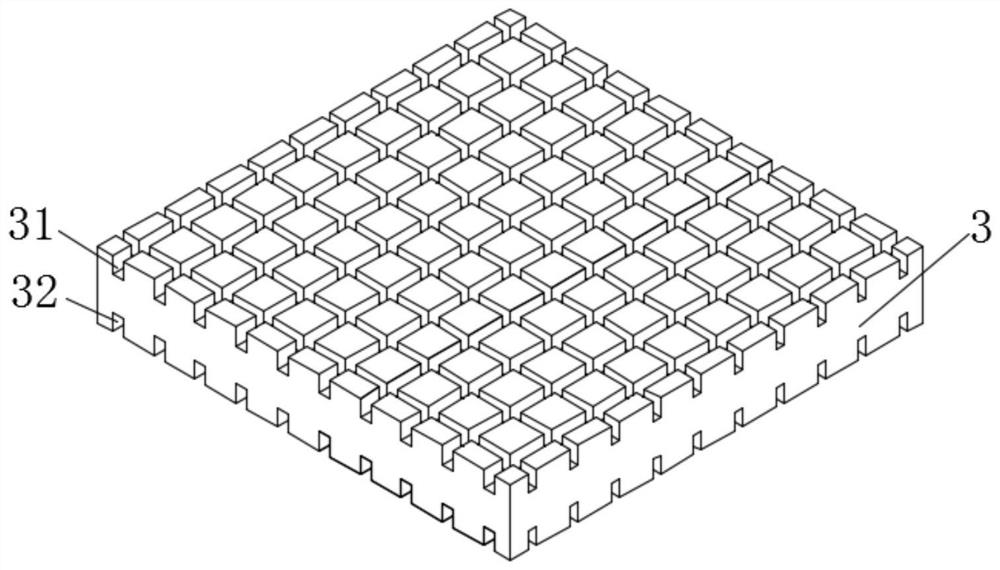

[0026] Such as Figure 1~2 As shown, an alkene-carbon heat-conducting film applied to 5G terminals provided in this embodiment includes a carbon heat-conducting sheet layer 1, a first diamond layer 2, a graphene heat-conducting layer 3, and a second diamond layer 4 in order from bottom to top; The carbon heat-conducting sheet layer 1 includes a metal substrate 11 and a nano-carbon layer 12 arranged on the upper surface of the metal substrate 11; the upper end surface of the graphene heat-conducting layer 3 is provided with first grooves 31 arranged in a grid shape, and the graphene heat-conducting layer 3 The lower end surface is provided with second grooves 32 arranged in a grid pattern; the first diamond layer 2 is deposited in the first groove 31, and the second diamond layer 4 is deposited in the second groove 32; the carbon heat conducting sheet The thickness ratio of the layer 1, the first diamond layer 2, the graphene heat conducting layer 3 and the second diamond layer...

Embodiment 2

[0029] Different from Embodiment 1, an insulating layer 5 is arranged on the upper layer of the second diamond layer 4 in this embodiment, and the insulating layer 5 is one of PE insulating layer, heat-conducting silica gel insulating layer or expanded polytetrafluoroethylene insulating layer. kind. The insulating layer 5 and the second diamond layer 4 are bonded by one of ultra-high temperature thermally conductive glue, polyethylene glue, silicone thermally conductive glue or epoxy resin AB glue. The thickness of the insulating layer 5 is 0.02-0.05mm, which can effectively The functions of insulation, high temperature resistance and wear resistance enhance the performance of olefinic carbon thermal conductivity film.

[0030] Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0032] Different from Embodiment 2, the upper layer of the insulating layer 5 of the present embodiment is provided with a flame-retardant layer 6, and the flame-retardant layer 6 includes a polyester layer and a polyamide resin layer, and the thickness ratio of the insulating layer, the flame-retardant layer, and the graphene heat-conducting layer is For 1-2:1-2:4-6. The insulating layer 5 and the flame-retardant layer 6 are bonded by one of ultra-high temperature thermally conductive glue, polyethylene glue, silicone thermally conductive glue or epoxy resin AB glue. The thickness of the flame-retardant layer 6 is 0.02-0.05mm, polyester and amide Resin has the advantages of high temperature resistance, corrosion resistance, oil resistance, impact resistance and good processing performance. Through this structural design, the insulation layer 5 and the flame retardant layer 6 cooperate to make the olefinic carbon heat conduction film achieve the advantages of good flame retarda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com