Low-frequency magnetic dielectric composite wave-absorbing patch and preparation method thereof

A technology of wave-absorbing patch and magnetic medium, which is applied in the field of wave-absorbing materials, can solve the problems that the excellent characteristics are difficult to be fully utilized, and the MAX phase material lacks a magnetic loss mechanism, etc., to achieve industrial application, low cost, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

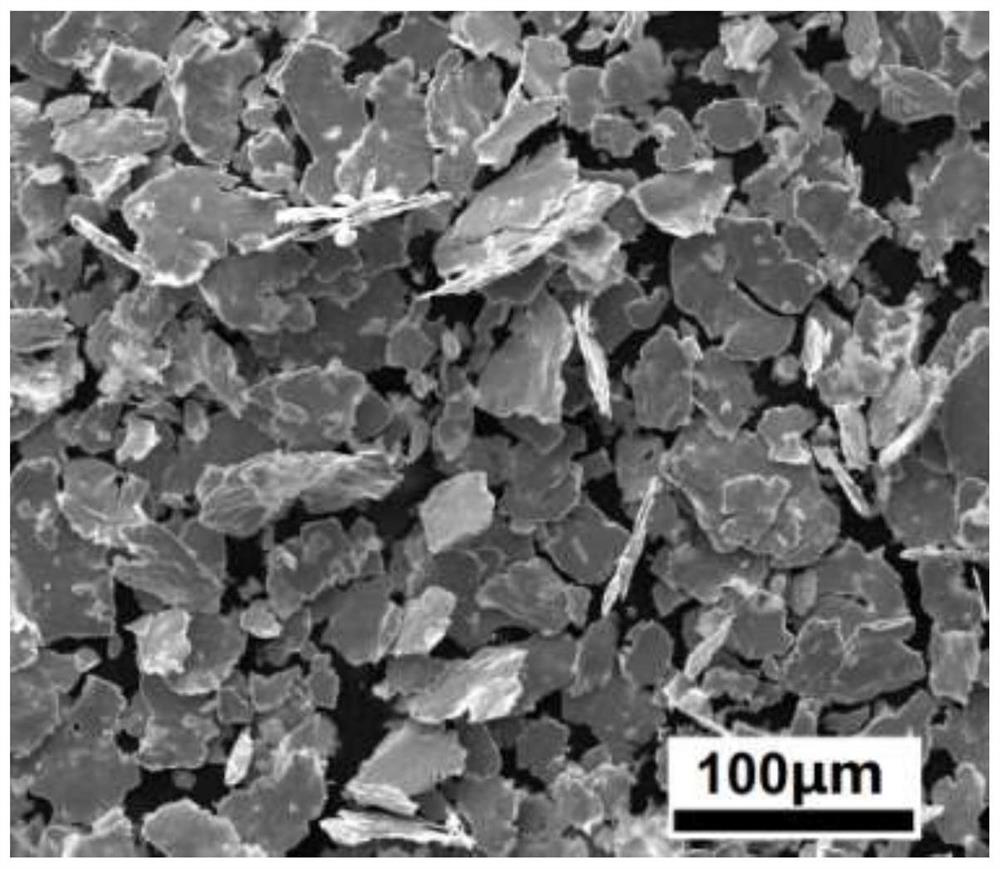

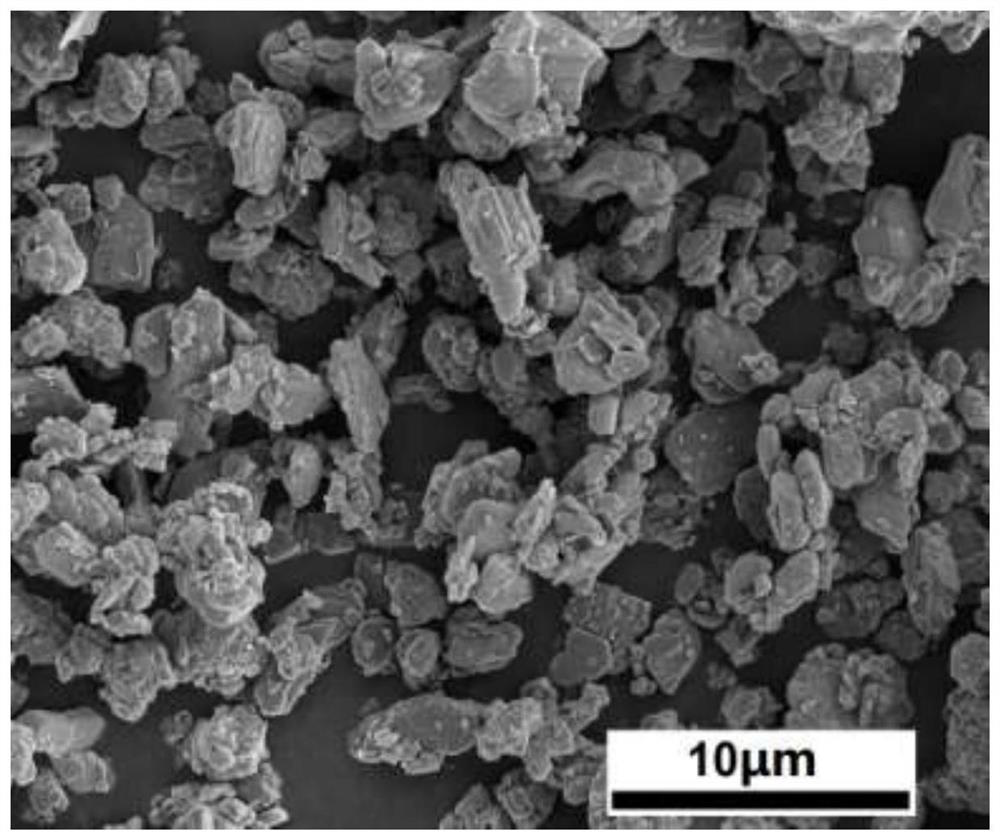

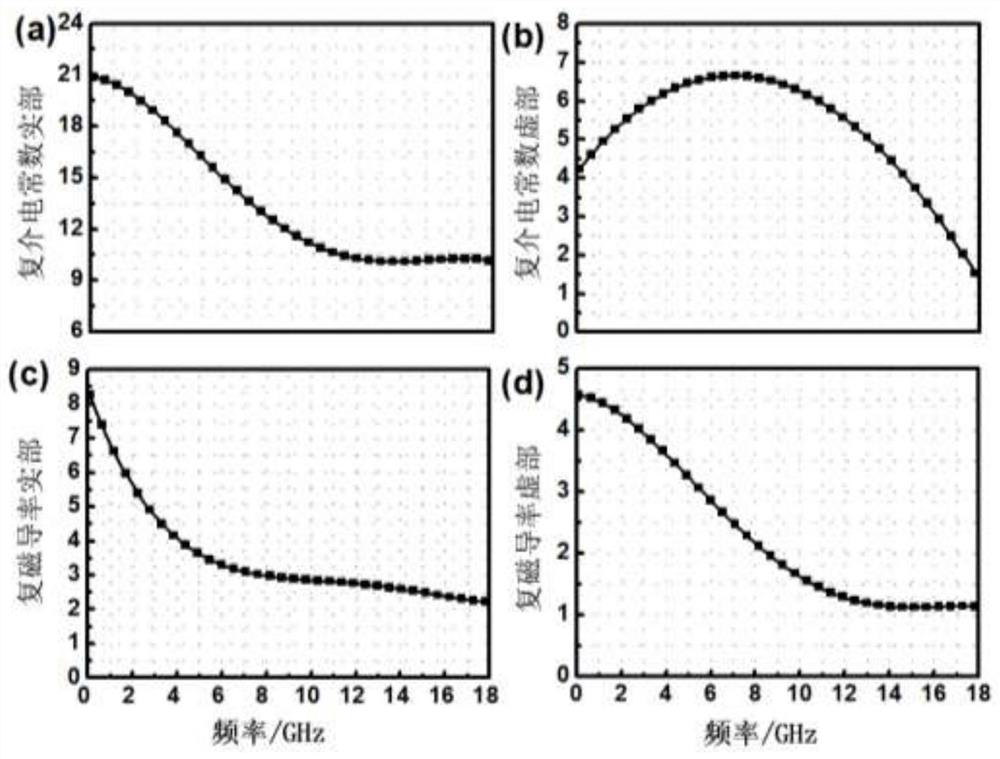

[0029] In this embodiment, the rubber is polyurethane rubber elastomer, and the functional additives filled include flame retardant, wetting and dispersing agent, vulcanizing agent, plasticizer and toughening agent, and the electromagnetic wave absorbing agent filled is flaky FeSiCr magnetic powder and Ti 3 SiC 2 MAX phase ceramic powder, low-frequency magnetic dielectric composite wave-absorbing patch with a thickness of 1.5mm and an area density of 3.2kg / m 2 .

[0030] The preparation method of the low-frequency magnetic medium composite wave-absorbing patch of this embodiment includes the following steps:

[0031] (1) Mix 1.0kg EPDM particles, 1.5kg flake FeSiCr magnetic powder, 2.0kgTi 3 SiC 2 MAX

[0032] Phase ceramic powder and 0.2kg flame retardant, 0.04kg wetting and dispersing agent, 0.03kg vulcanizing agent and 0.01kg plasticizer

[0033] Put it into the banburying equipment and heat it to 60°C, stir and mix for 2 hours to obtain a uniformly mixed premix;

[0...

Embodiment 2

[0044] In this embodiment, the rubber is polyolefin elastomer rubber, the functional additives filled include flame retardants, wetting and dispersing agents, vulcanizing agents and plasticizers, and the filled electromagnetic wave absorbers are flake FeSiAl and Ti 3 AlC 2 MAX phase ceramic powder, low-frequency magnetic dielectric composite wave-absorbing patch with a thickness of 1.5mm and an area density of 3.2kg / m 2 .

[0045] The preparation method of the low-frequency magnetic medium composite wave-absorbing patch of this embodiment includes the following steps:

[0046] (1) Mix 1.2kg polyolefin elastomer rubber particles, 1.0kg flake FeSiAl magnetic powder, 1.5kgTi 3 AlC 2

[0047] MAX phase ceramic powder, 0.4kg flame retardant, 0.03kg wetting and dispersing agent, 0.04kg vulcanizing agent, 0.01kg plasticizer and 0.01kg toughening agent were put into the banburying equipment and heated to 50°C and stirred for 4 hours to obtain Mixed homogeneous premix;

[0048] (...

Embodiment 3

[0054] In this embodiment, the rubber is polyurethane rubber elastomer, the functional additives filled include flame retardant, wetting and dispersing agent, vulcanizing agent and plasticizer, and the electromagnetic wave absorber filled is flaky FeCoZr magnetic powder and Ti 3 SiC 2 MAX phase ceramic powder, low-frequency magnetic dielectric composite wave-absorbing patch with a thickness of 1.0mm and an area density of 2.8kg / m 2 .

[0055] The preparation method of the low-frequency magnetic medium composite wave-absorbing patch of this embodiment includes the following steps:

[0056] (1) Mix 0.8kg polyurethane rubber particles, 1.2kg flake FeCoZr magnetic powder, 1.5kgTi 3 SiC 2 MAX

[0057] Phase ceramic powder, 0.2kg flame retardant, 0.04kg wetting and dispersing agent, 0.02kg vulcanizing agent, 0.01kg plasticizer and 0.01kg toughening agent were put into the banburying equipment and heated to 60°C for 3 hours, and the mixture was prepared. Homogenized premix;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com