Laser-excited fluorescent glass film and preparation method thereof

A technology for exciting fluorescent and fluorescent glass, which is applied in the direction of climate sustainability, sustainable architecture, and energy-saving lighting. Avoid the decline of heat dissipation performance, improve light efficiency and color rendering performance, and avoid the effect of easy cracking of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

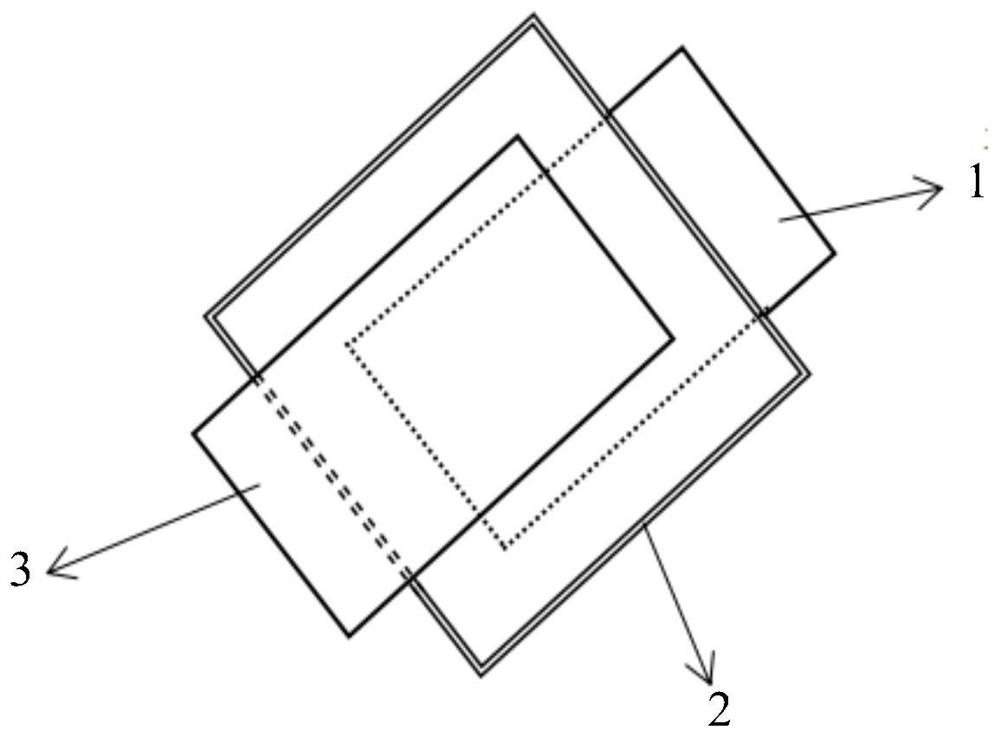

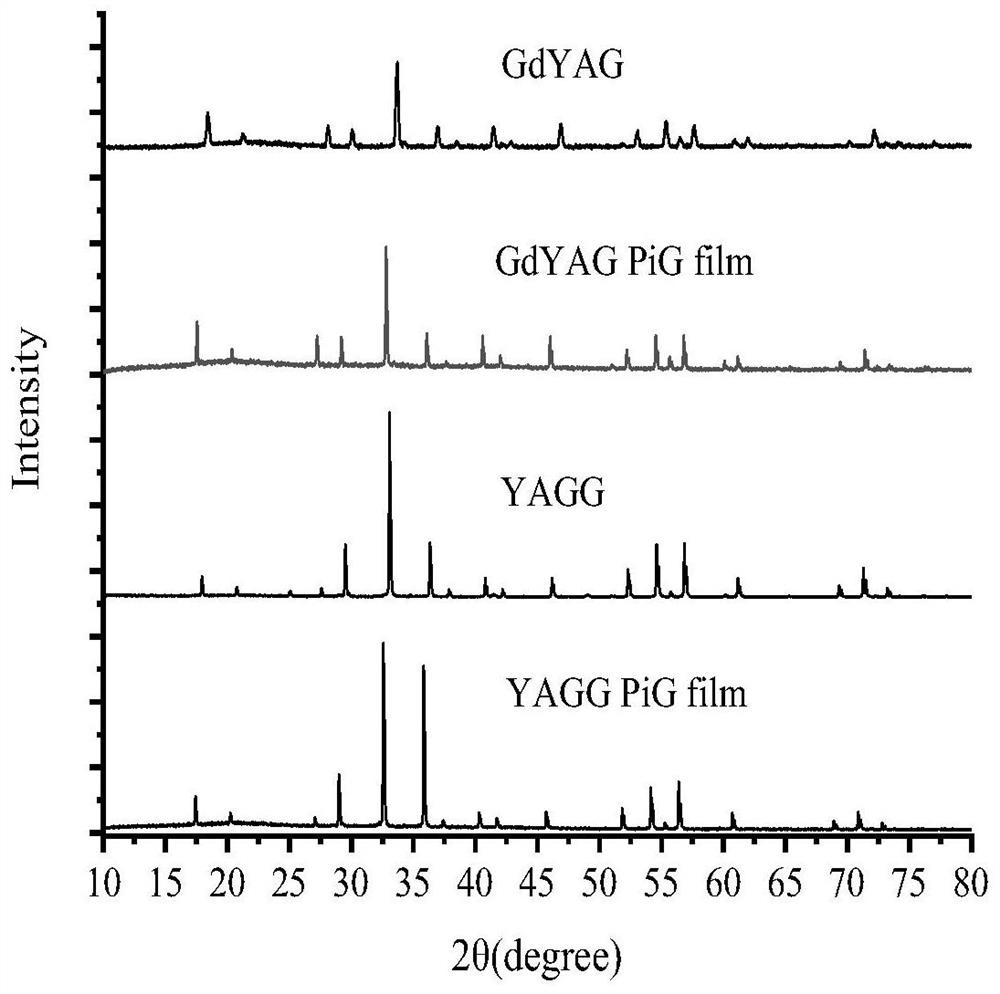

[0040] Embodiment 1: a kind of fluorescent glass thin film, by the commercial K of 50wt% 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder with 50wt% YAGG:Ce 3+ Yellow-green phosphor, 50wt% commercial K 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder with 50wt% GdYAG:Ce 3+ The orange phosphors are composed separately.

[0041] Will commercially use YAGG:Ce 3+ Phosphor powder (Suzhou Lanbo Photoelectric Technology Co., Ltd.) and GdYAG:Ce 3+ Phosphor powder (Suzhou Lanbo Photoelectric Technology Co., Ltd.) and commercial K 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder (Changzhou Wujin Xinghai Chemical Co., Ltd.) is weighed according to the ratio of mass ratio 1:1, mixed evenly, and organic slurry is added. The organic slurry is made of ethyl acetate (Shanghai Aladdin Biochemical Co., Ltd., ≥88.5%) ), ethyl cellulose (Shanghai Aladdin Biochemical Co., Ltd., 18-22mPa.S), terpineol (Shanghai Aladdin Biochemical Co., Ltd., 85%) were mixed evenly in a mass ratio of 3:1:16 Prepared by stirr...

Embodiment 2

[0045] Embodiment 2: a kind of fluorescent glass thin film, by the commercial K of 50wt% 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder with 50wt% YAG: Ce 3+ Composition of yellow fluorescent powder.

[0046] Commercial YAG: Ce 3+ Phosphor commercial K 2 O-Na 2 O-Al 2 o 3 -SiO 2 Weigh and mix the glass powder according to the mass ratio of 1:1, add the organic slurry and stir until it becomes gelatinous, and coat two layers of YAG: Ce on both sides of the sapphire substrate respectively. 3+ PiG and a layer of YAG: Ce 3+ PiG is cured and formed on a heating platform and then placed in a muffle furnace. The temperature is raised to a maximum temperature of 750°C at a room temperature of 25°C and kept at a temperature of 10 minutes. The temperature is lowered to a room temperature of 25°C and taken out to obtain a fluorescent glass film.

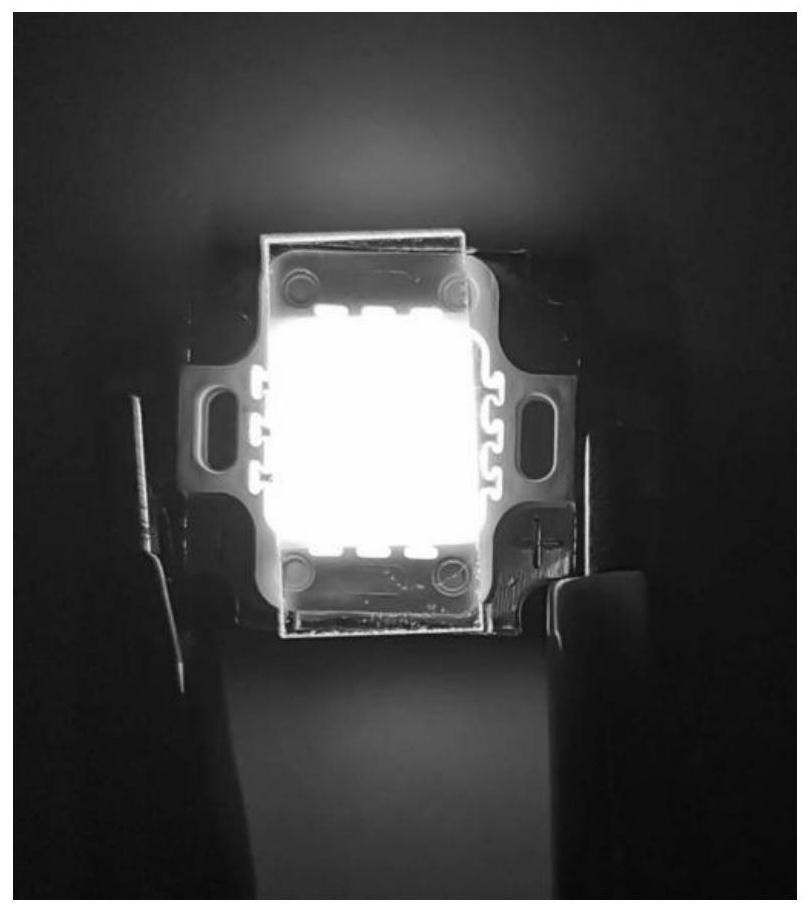

[0047] Fluorescent glass thin film prepared in embodiment 1 and single YAG in embodiment 2: Ce 3+ Optical performance comparison of fluo...

Embodiment 3

[0048] Embodiment 3: a kind of fluorescent glass thin film, by the commercial K of 50wt% 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder with 50wt% YAGG:Ce 3+ Yellow-green phosphor, 50wt% commercial K 2 O-Na 2 O-Al 2 o 3 -SiO 2 Glass powder with 50wt% GdYAG:Ce 3+ The orange phosphors are composed separately.

[0049] Will commercially use YAGG:Ce 3+ Phosphor and GdYAG:Ce 3+ Phosphors were compared with commercial K 2 O-Na 2 O-Al 2 o 3 -SiO 2 Weigh and mix the glass powder according to the mass ratio of 1:1, add the organic slurry and stir until it becomes gelatinous, and coat a layer of YAGG:Ce on both sides of the sapphire substrate respectively. 3+ PiG and two layers of GdYAG:Ce 3+ PiG, after being solidified on a heating table, placed in a muffle furnace, heated to a maximum temperature of 750°C at a room temperature of 25°C (the optimum sintering temperature is related to the glass powder matrix, and the glass powder used in our prepared samples is the same , so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color temperature | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com