Integrated purification system for complex flue gas

A purification system and flue gas technology, applied in air quality improvement, chemical instruments and methods, separation of dispersed particles, etc., can solve the problem of high oxidation cost, achieve high absorption efficiency, reduce mass transfer distance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

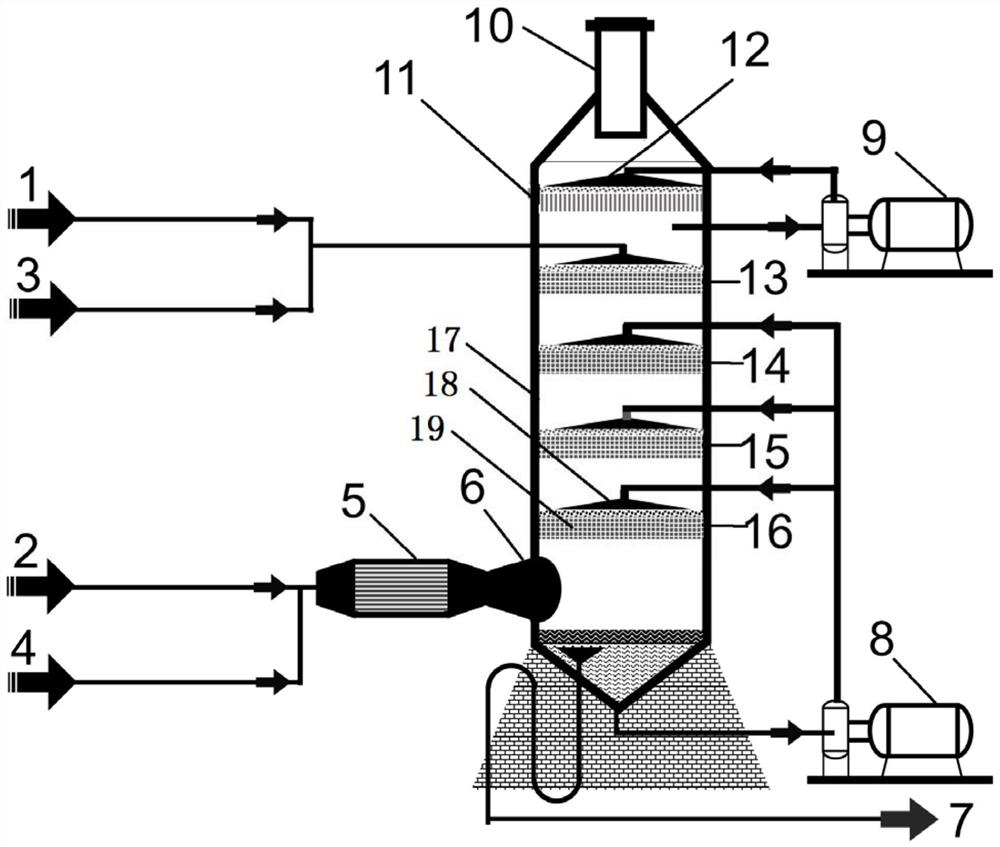

[0037] An integrated complex flue gas purification system, the system is composed of a catalytic oxidation device 5 and an absorption and washing device, the absorption and washing device includes a washing tower 17, and at least two stages of spray washing are arranged in the washing tower in sequence from bottom to top In this embodiment, four-stage spray scrubbers are set, which are respectively the first-stage scrubber shower 13, the second-stage scrubber shower 14, the third-stage scrubber shower 15, the fourth-stage scrubber shower 16, and the cleaner , dedusting and mist eliminator 11 and chimney 10; the bottom of the washing tower is provided with a flue gas inlet 6, and the spray scrubber is arranged above the flue gas inlet, and the flue gas inlet is connected with the catalytic oxidation device; the spray washing The device is composed of circulating spray pump A8, nozzle 18 and microchannel filler 19. The spray pump transports the washing liquid composed of process ...

Embodiment 2

[0051] In addition to adding process gas 4 to contain O 3 air, where O 3 The mol ratio with NO is 0.2, and all the other processes and parameters are the same as in Example 1.

[0052] The SOx removal rate of the system is greater than 99%, and the NOx removal rate is greater than 90%.

[0053] The desulfurization, denitrification and dedusting process in the present invention is implemented based on the above-mentioned equipment, so this process also has the technical effect of the above-mentioned equipment. In short, according to the flue gas purification system of the embodiment of the present invention, the flue gas in the flue gas source first enters the catalytic oxidation device 5, and the insoluble NO in the flue gas is oxidized into water-soluble NO 2 , the oxidized flue gas enters the washing tower 7 and reacts with the washing liquid in the washing tower to realize the synchronous removal of NOx and SOx in the flue gas. Smaller and more environmentally friendly. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com