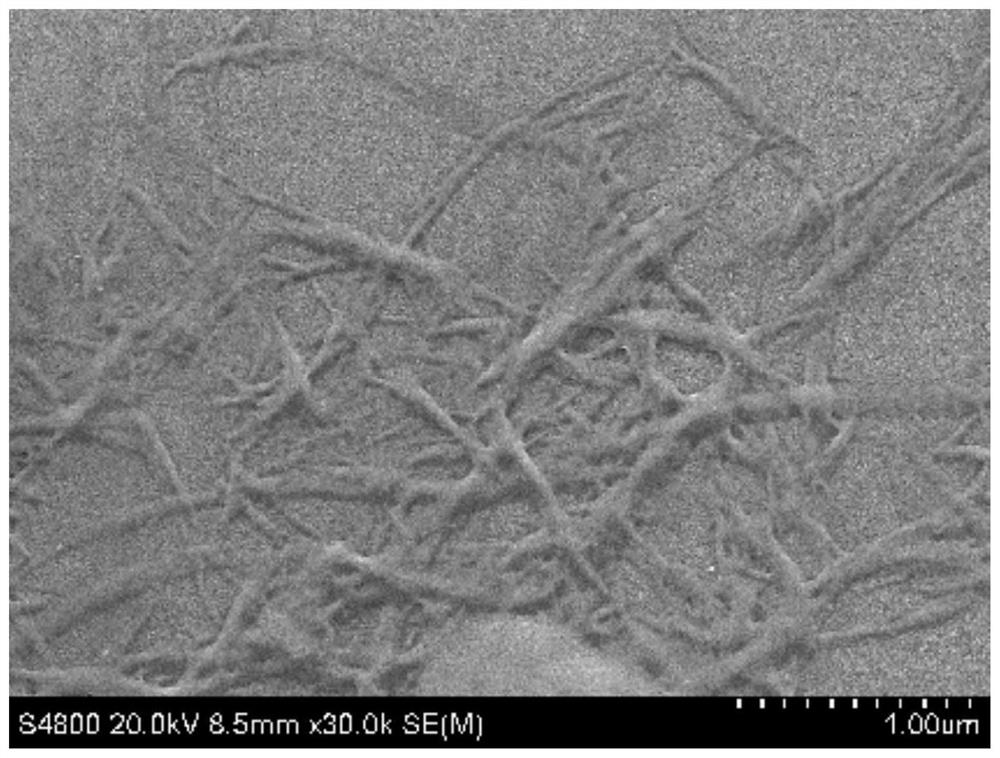

Preparation method of bacterial cellulose composite collagen self-assembly material

A technology of bacterial cellulose and collagen, which is applied in the field of preparation of natural polymer materials, can solve the problems of complicated process, long preparation time, poor controllability, etc., and achieve improved swelling rate, excellent biocompatibility, and shortened preparation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the bacterial cellulose composite collagen self-assembly material of the present embodiment comprises the following steps:

[0027] (1) Dissolve the fish skin collagen powder in a phosphate buffer solution with a pH of 7.4 to form a 2000 μg / mL fish collagen solution;

[0028] (2) Add 200 mg of bacterial cellulose homogenate (10% solid content) into 10 mL of fish skin collagen solution, adjust the pH of the solution to 8.5, stir ultrasonically for 10 min, and then stand at 37°C for 12 h for self-assembly;

[0029] (3) Put the prepared bacterial cellulose composite fish collagen self-assembly solution into a dialysis bag with a molecular weight cut-off of 8,000 to 14,000 Daltons, perform dialysis for 12 hours, and change the water every 4 hours;

[0030] (4) Add 1 mL of 5% glycerin and 0.1 mg of nano-silver particles to the bacterial cellulose composite fish collagen self-assembly solution after dialysis, and disperse with ultrasonic stirring for...

Embodiment 2

[0033] The preparation method of the bacterial cellulose composite collagen self-assembly material of the present embodiment comprises the following steps:

[0034] (1) Take an appropriate amount of bovine serum collagen powder and dissolve it in a phosphate buffer solution with a pH of 7.4 to form a bovine serum collagen solution of 1000 μg / mL;

[0035] (2) Mix 2.5 mg of bacterial cellulose dry powder with 50 mL of bovine serum collagen solution, adjust the pH of the solution to 8.0, ultrasonically disperse for 30 min, and then stand at 25°C for 24 h for self-assembly;

[0036] (3) Put bacterial cellulose composite bovine serum collagen self-assembly solution into a dialysis bag with a molecular weight cut-off of 8,000-14,000 Daltons, and change the water every 4 hours for dialysis for 24 hours;

[0037] (4) Add 1.5 mL of 5% glycerin and 0.2 mg of nano-silver particles to the dialysis bacterial cellulose composite bovine serum collagen self-assembly solution, and disperse wit...

Embodiment 3

[0041] The preparation method of the bacterial cellulose composite collagen self-assembly material of the present embodiment comprises the following steps:

[0042] (1) dissolving rat tail collagen in a phosphate buffer solution with a pH of 7.4 to prepare a 100 μg / mL rat tail collagen solution;

[0043] (2) Mix 0.2 mg of bacterial cellulose dry powder with 10 mL of rat tail collagen solution, adjust the pH of the solution to 8.0, ultrasonically disperse for 30 min, and then stand at 35°C for 4 h for self-assembly;

[0044] (3) Put bacterial cellulose composite bovine serum collagen self-assembly solution into a dialysis bag with a molecular weight cut-off of 8,000-14,000 Daltons, and change the water every 4 hours for dialysis for 24 hours;

[0045] (4) Add 0.2 mL of 5% glycerin and 0.05 mg of nano-silver particles to the dialysis bacterial cellulose composite rat tail collagen self-assembly solution, and disperse with ultrasonic stirring for 30 min;

[0046] (5) Add 0.5% modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com