Chitin nanocrystalline composite collagen self-assembly method

A chitin nanocrystal, collagen technology, applied in the direction of cellulose/protein conjugated rayon, textile and papermaking, conjugated rayon, etc., can solve the problem of single structure and function of self-assembled products, self-assembly of collagen Harsh conditions and other problems, to achieve the effect of improving the self-assembly process, the reaction process is simple and controllable, and the reaction conditions are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) configure the chitin nanocrystal aqueous solution of 20 μg / mL;

[0027] (2) Take fish skin collagen and dissolve it in water, and use a phosphate buffer solution with a pH of 7.4 to prepare a 200 μg / mL fish skin collagen solution;

[0028] (3) 1mL chitin nanocrystal solution was ultrasonically dispersed and mixed with 5mL fish skin collagen solution, stirred ultrasonically for 10min, and then left at 40°C for 5.5h for self-assembly;

[0029] (4) Put the prepared chitin nanocrystal composite fish skin collagen self-assembly solution into a dialysis bag with a molecular weight cut-off of 8,000 to 14,000 Daltons, and change the water every 4 hours for dialysis for 24 hours;

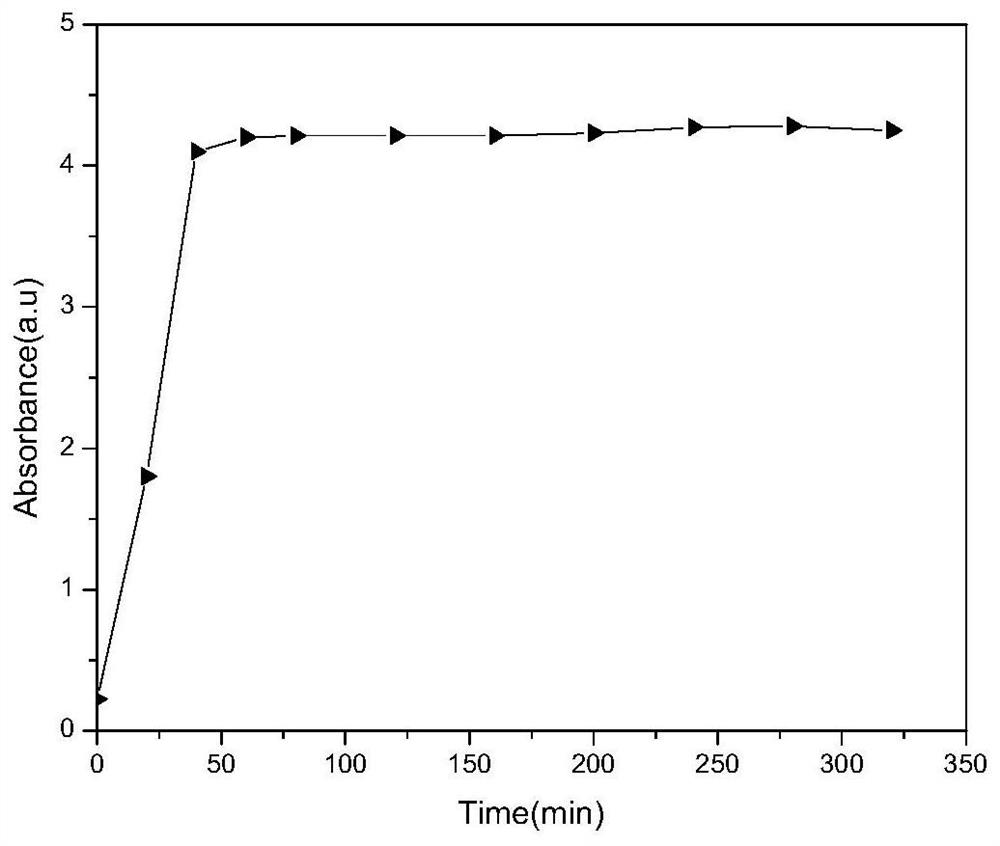

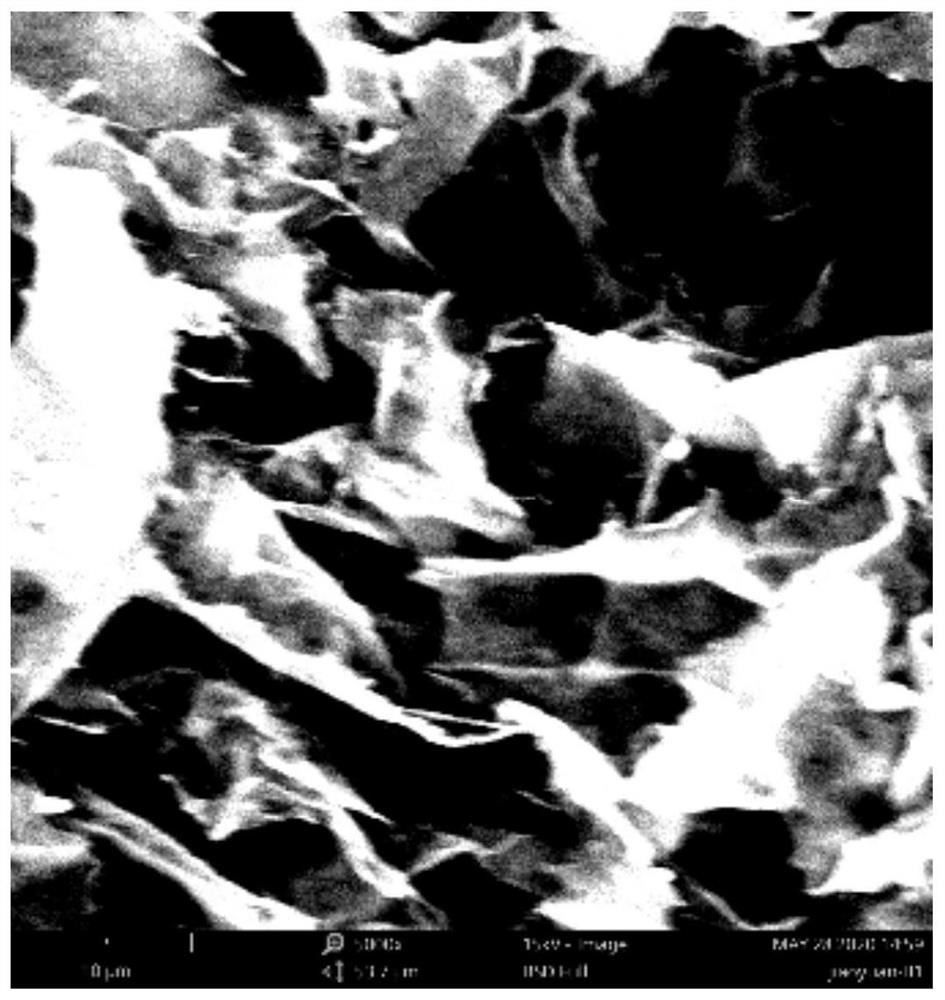

[0030] (5) After centrifuging the chitin nanocrystal composite fish skin collagen self-assembly solution after dialysis, take out the lower precipitate, add 1 mL of 2% glutaraldehyde solution, fix it for 120 min, wash it with water for 3 times, and freeze-dry it in a freeze dryer . The UV spectr...

Embodiment 2

[0032] (1) configure the chitin nanocrystal aqueous solution of 100 μg / mL;

[0033] (2) After dissolving the bovine tendon collagen in water, use a phosphate buffer solution with a pH of 7.4 to configure a 1000 μg / mL bovine collagen solution;

[0034] (3) 1.5 mL of chitin nanocrystal solution was ultrasonically dispersed and mixed with 5 mL of bovine tendon collagen solution, stirred ultrasonically for 10 min, and then left at 35°C for 6 h for self-assembly;

[0035] (4) The prepared chitin nanocrystal composite bovine tendon collagen self-assembly solution is packed into a dialysis bag with a molecular weight cut-off of 8000-14000 Daltons, and the water is changed every 4 hours for dialysis for 24 hours;

[0036] (5) After centrifuging the dialyzed chitin nanocrystal composite bovine bone collagen self-assembly solution, take out the lower precipitate, add 1.5% formaldehyde solution 1.5mL to fix it for 100min, wash it with water three times, and freeze-dry it in a freeze drye...

Embodiment 3

[0038] (1) configure the chitin nanocrystal aqueous solution of 1 μg / mL;

[0039] (2) Take rat tail collagen and dissolve it in glacial acetic acid, and use a phosphate buffer solution with a pH of 7.4 to prepare a 20 μg / mL rat tail collagen solution;

[0040] (3) 1mL chitin nanocrystal solution was ultrasonically dispersed and mixed with 5mL rat tail collagen solution, stirred ultrasonically for 10min, and then left at 37°C for 2h for self-assembly;

[0041] (4) Put the prepared chitin nanocrystal composite rat tail collagen self-assembly solution into a dialysis bag with a molecular weight cut-off of 8,000 to 14,000 Daltons, and change the water every 2 hours for dialysis for 12 hours;

[0042] (5) After centrifuging the chitin nanocrystal composite rat tail collagen self-assembly solution after dialysis, take out the lower sediment, add 0.5% modified glutaraldehyde solution 0.5mL and fix it for 100min, wash it with water 3 times, and then put it in a freeze dryer Freeze-dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com