Preparation method of composite rare earth permanent magnet material and anti-oxidation mixing equipment

A technology of permanent magnet materials and composite rare earths, applied in the fields of magnetic materials, inorganic materials, chemical instruments and methods, etc., can solve the problems of waste of resources and environment, easy to be oxidized, and low oxidation prevention efficiency, and achieve reasonable design and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a composite rare earth permanent magnet material, comprising the steps of:

[0038] Step 1, batching, a composite rare earth permanent magnet material includes the following raw materials in weight percentage: 48% of neodymium iron boron magnetic powder, 20% of ferrite magnetic powder, 8% of samarium cobalt magnetic powder, 4% of alnico magnetic powder, polytetrafluoroethylene 1.5%, potassium sorbate 0.4%, acrylate resin 8%, polyethylene terephthalate-1,4-cyclohexanedimethanol 6%, silane coupling agent 1.6%, titanate coupling Agent 1.3%, graphite 0.7%, barium stearate 0.5%;

[0039] Step 2, smelting: the prepared materials are respectively passed through the large furnace and the small furnace to cast flakes or ingots;

[0040] Step 3, hydrogen crushing: use the hydrogen absorption properties of rare earth metal compounds to fuse rare earth alloys in a hydrogen environment;

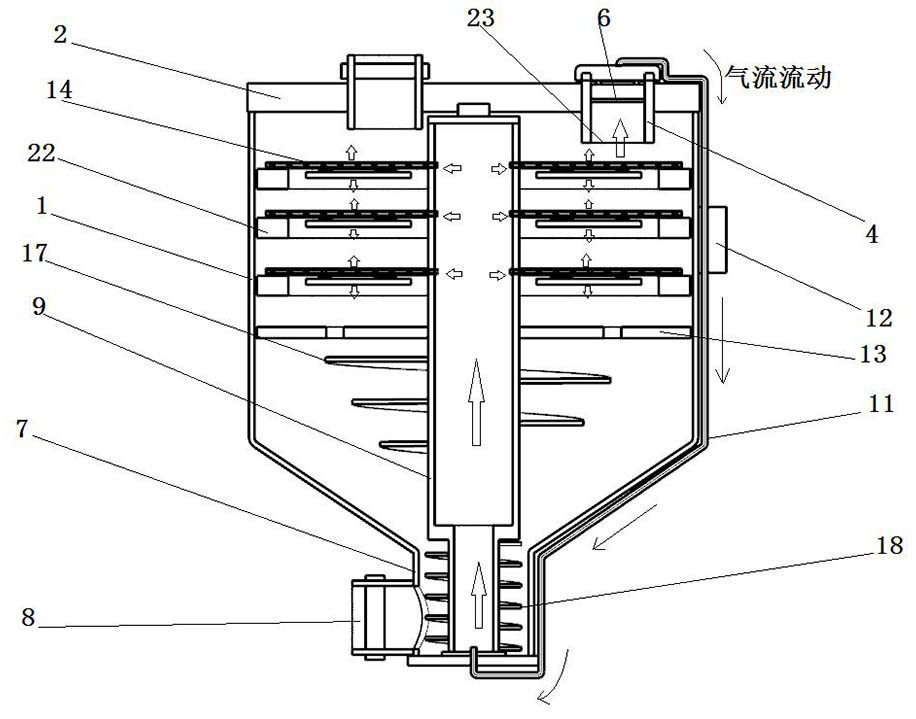

[0041] Step 4, milling and mixing: use anti-oxidation mixing equipmen...

Embodiment 2

[0044] A preparation method of a composite rare earth permanent magnet material, comprising the steps of:

[0045] Step 1, batching, a composite rare earth permanent magnet material includes the following raw materials in weight percentage: 50% of neodymium iron boron magnetic powder, 22% of ferrite magnetic powder, 4% of samarium cobalt magnetic powder, 4% of alnico magnetic powder, and 0.7% of polytetrafluoroethylene %, potassium sorbate 0.3%, acrylate resin 8.5%, polyethylene terephthalate-1,4-cyclohexanedimethanol 6%, silane coupling agent 1.6%, titanate coupling agent 1.3%, graphite 0.8%, barium stearate 0.8%;

[0046] Step 2, smelting: the prepared materials are respectively passed through the large furnace and the small furnace to cast flakes or ingots;

[0047] Step 3, hydrogen crushing: use the hydrogen absorption properties of rare earth metal compounds to fuse rare earth alloys in a hydrogen environment;

[0048] Step 4, milling and mixing: use anti-oxidation mixi...

Embodiment 3

[0051] A preparation method of a composite rare earth permanent magnet material, comprising the steps of:

[0052] Step 1, batching, a composite rare earth permanent magnet material includes the following raw materials in weight percentage: 44% of neodymium iron boron magnetic powder, 22% of ferrite magnetic powder, 8% of samarium cobalt magnetic powder, 6% of alnico magnetic powder, polytetrafluoroethylene 0.3%, potassium sorbate 0.4%, acrylate resin 8%, polyethylene terephthalate-1,4-cyclohexanedimethanol 7.5%, silane coupling agent 1.7%, titanate coupling Agent 1.3%, graphite 0.3%, barium stearate 0.5%;

[0053] Step 2, smelting: the prepared materials are respectively passed through the large furnace and the small furnace to cast flakes or ingots;

[0054] Step 3, hydrogen crushing: use the hydrogen absorption properties of rare earth metal compounds to fuse rare earth alloys in a hydrogen environment;

[0055] Step 4, milling and mixing: use anti-oxidation mixing equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com