Application of an ion-conducting membrane containing chlorinated polyvinyl chloride in a flow battery

A technology of chlorinated polyvinyl chloride and ion-conducting membranes, applied in fuel cells, regenerative fuel cells, aqueous electrolyte fuel cells, etc., can solve the problems of membrane stability degradation and achieve increased solubility and molecular bond polarity , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 (preferred)

[0040] Dissolve CPVC (degree of chlorination 72%) and polyvinylpyrrolidone (PVP, degree of quaternization 100%) in an organic solvent, stir fully at 25°C for 48 hours to make a blend solution; wherein the mass concentration of CPVC is 10 %, the mass concentration of PVP is 15%; then pour the prepared CPVC / PVP blend solution directly on a glass plate, and evaporate the solvent at 25°C; finally, immerse the glass plate in water at a temperature of 25°C for 1h , to prepare the CPVC ion-conducting membrane applied in the flow battery, CPVC The thickness of the ion-conducting membrane is 40 μm.

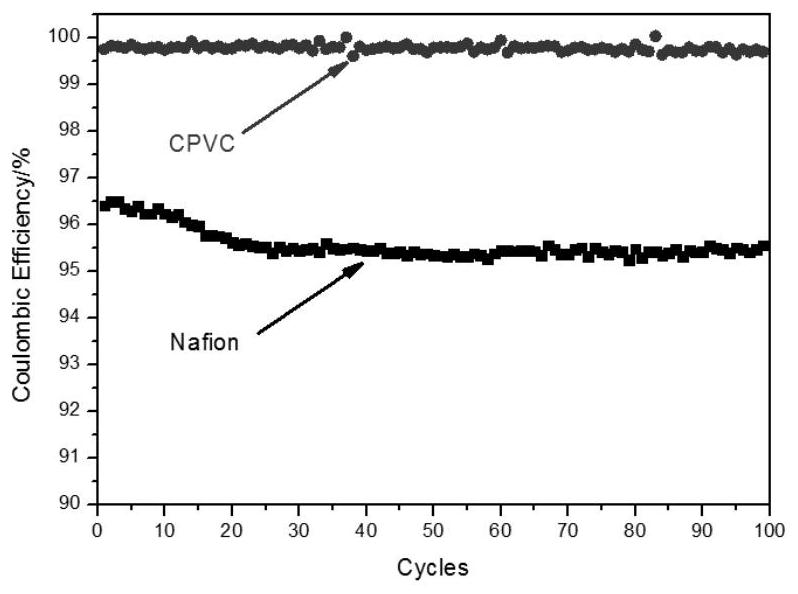

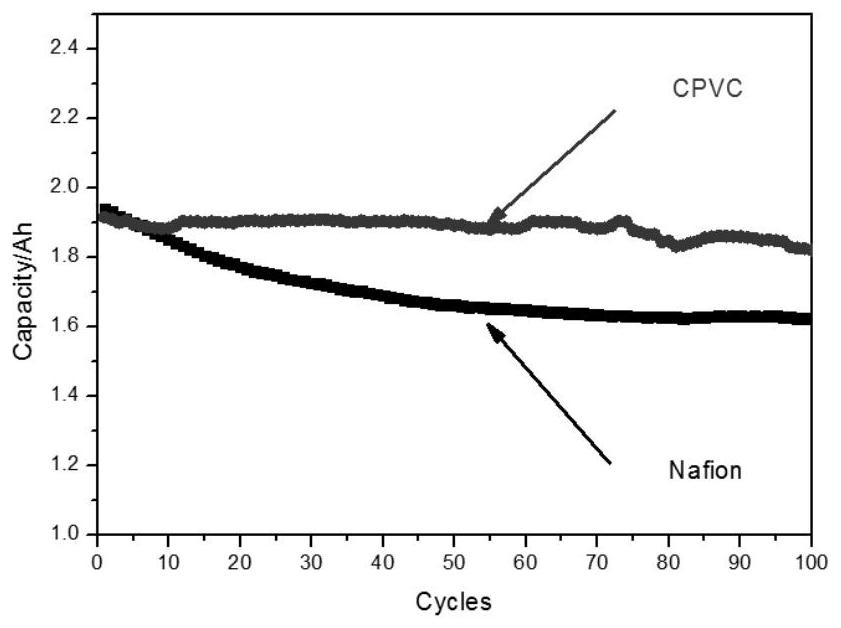

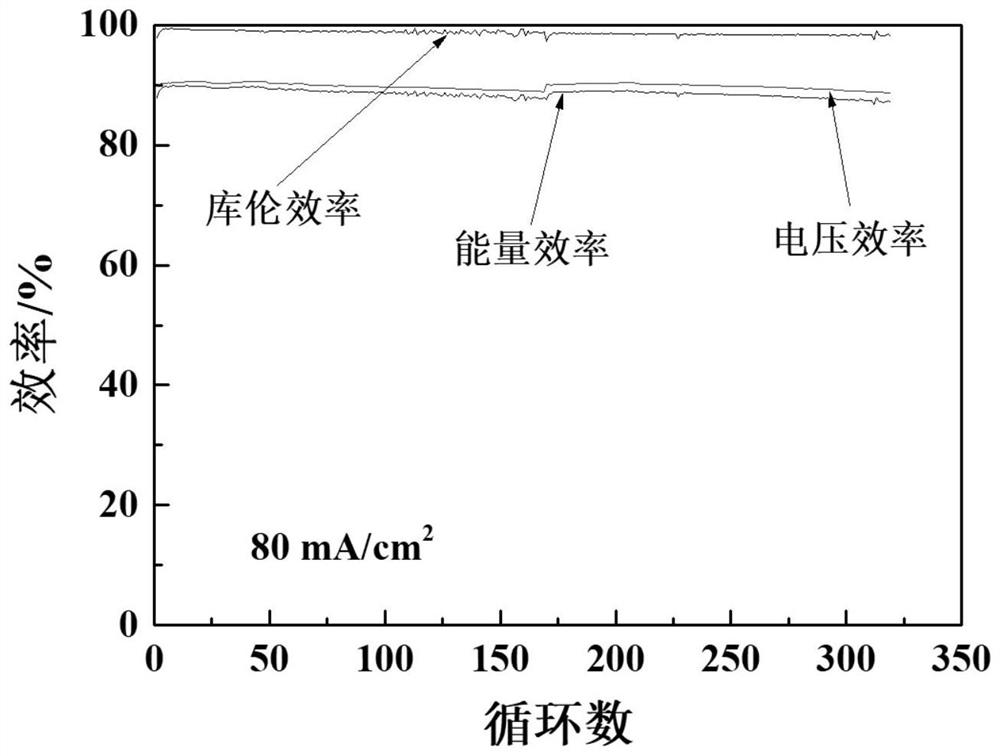

[0041] will be made CPVC The performance of the ion-conducting membrane was tested and compared with the performance of the commercialized perfluorosulfonic acid membrane Nafion 115 membrane. The present invention takes an all-vanadium redox flow battery as an example. Prepared CPVC As shown in Table 1, the surface resistance of the ion-conducting m...

Embodiment 2

[0044] Configure the film-forming solution according to the method described in the above-mentioned Example 1, the difference is that the mass concentration of PVP is 5%, and the prepared CPVC The thickness of the ion-conducting membrane is 40 μm.

[0045] will be made CPVC The performance of the ion-conducting membrane was tested, and compared with the performance of the CPVC ion-conducting membrane prepared in Example 1 and the Nafion 115 membrane. The present invention takes an all-vanadium redox flow battery as an example. Prepared in this example CPVC The surface resistance of the ion-conducting membrane is lower than the surface resistance of the Nafion 115 membrane, but higher than the surface resistance of the CPVC ion-conducting membrane prepared in Example 1, indicating that the decline of the ion-exchange resin content in the CPVC ion-conducting membrane reduces the ion conduction of the membrane rate (table 1); prepared in the present embodiment CPVC Vanadiu...

Embodiment 3

[0048] Configure the film-forming solution according to the method described in the above-mentioned Example 1, the difference is that the mass concentration of PVP is 25%, and the prepared CPVC The thickness of the ion-conducting membrane is 40 μm.

[0049] will be made CPVC The performance of the ion-conducting membrane was tested, and compared with the performance of the CPVC ion-conducting membrane prepared in Example 1 and the Nafion 115 membrane. The present invention takes an all-vanadium redox flow battery as an example. Prepared in this example CPVC The surface resistance of the ion-conducting membrane is lower than the surface resistance of the CPVC ion-conducting membrane prepared in Example 1 and the Nafion 115 membrane, showing that the increase of the ion-exchange resin content in the CPVC ion-conducting membrane has improved the ion conductivity of the membrane (Table 1) ; Prepared in this embodiment CPVC Vanadium ions (VO 2+ ) transmittance is higher tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com