Environment-friendly flue gas purification treatment device and using method thereof

A flue gas purification and treatment device technology, which is applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems that the reaction liquid cannot be recycled, cannot be processed and collected, and can save resources and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

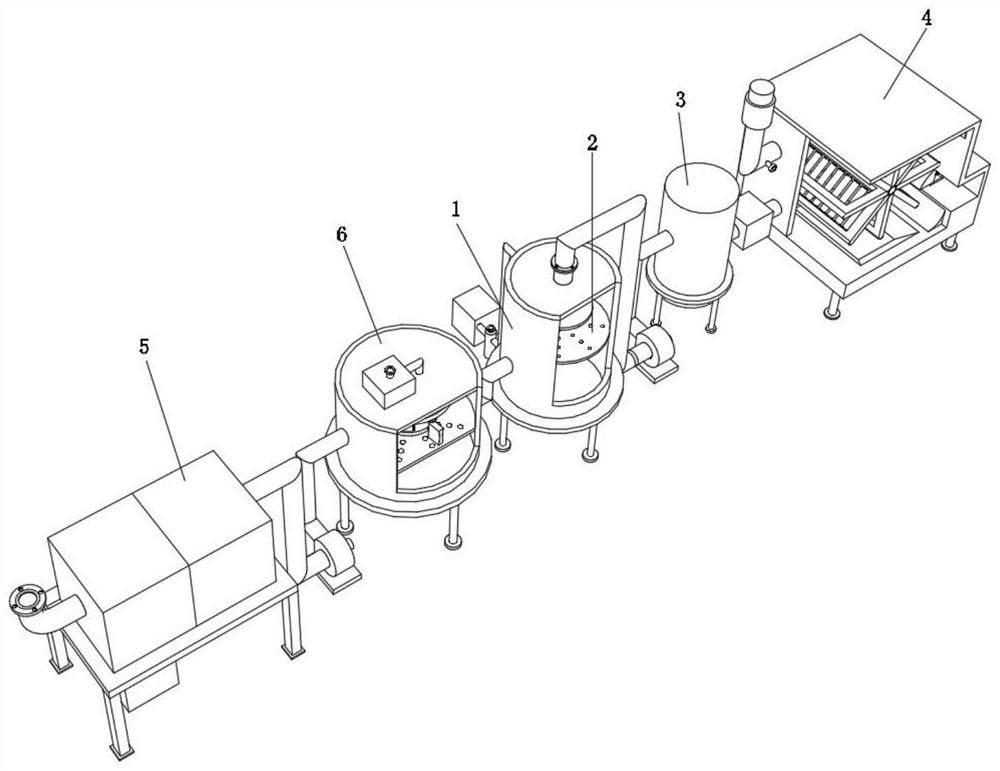

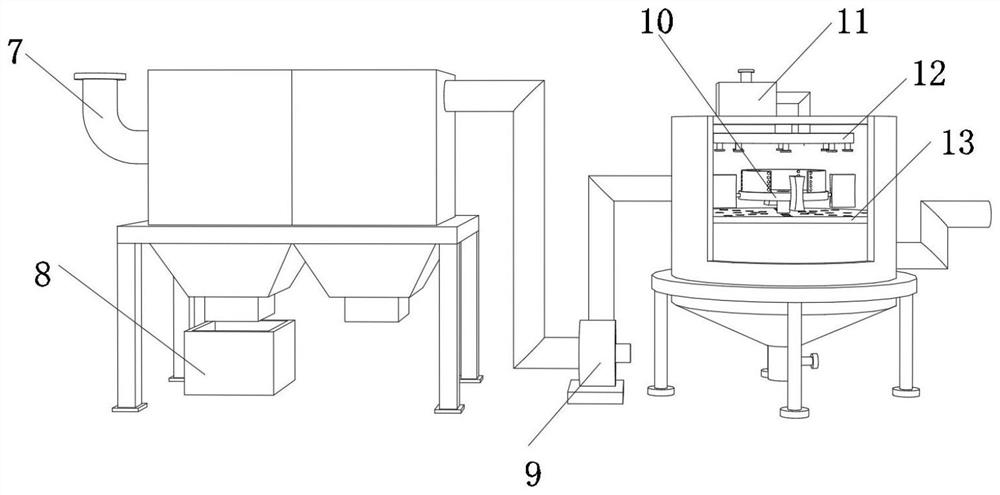

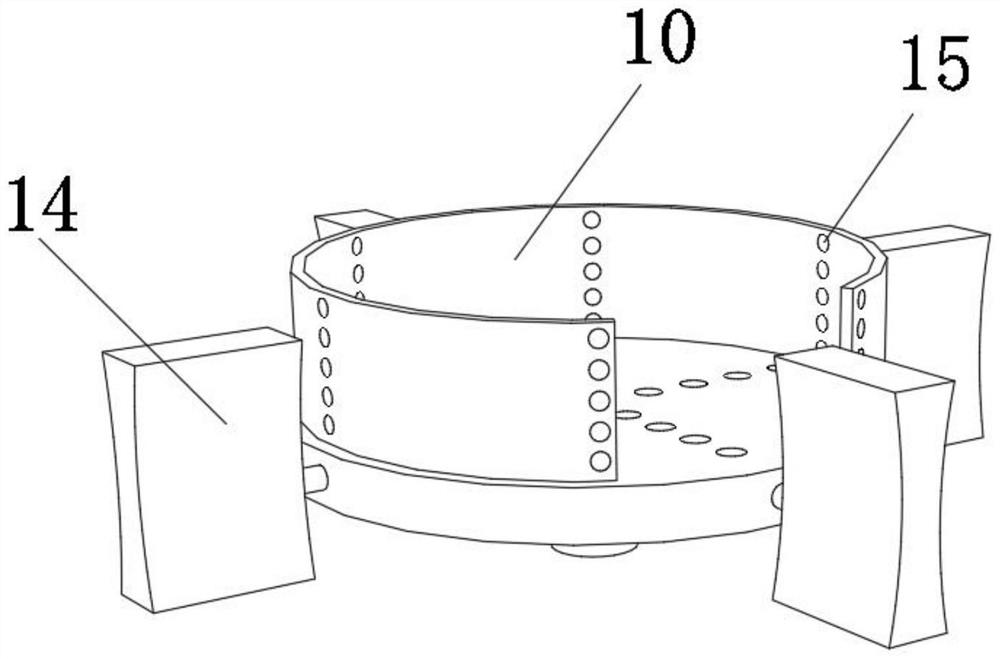

[0045] An environmentally friendly flue gas purification treatment device, such as Figure 1-5 As shown, it includes a desulfurization tower 1, a circulation pump one 22, a circulation pump two 25, a dehydration assembly 26 and a circulation pump three 28. Both the output end and the input end are connected with a connecting pipe 29 through a flange, one end of one of the connecting pipe 29 is fixed with a spray pipe 20 through a flange, and one end of the other connecting pipe 29 is connected with a flange. Calcium hydroxide solvent tank 23, described circulation pump two 25 output ends and input end all are connected with connecting pipe three 24 by flange, and one end of one of said connecting pipe three 24 is connected to calcium hydroxide solvent tank 23 by flange On the side outer wall, one end of the other connecting pipe 3 24 is connected to the return water tank 27 through a flange. The output end and the input end of the circulating pump 3 28 are connected to the con...

Embodiment 2

[0052] A method for using the environmentally friendly flue gas purification treatment device described in Embodiment 1, comprising the following steps:

[0053] S1: Lead the flue gas into the bag filter 5 through the flue gas inlet pipe 7;

[0054] S2: The flue gas filtered by the bag filter 5 enters the cooling tower 6 through the induced draft fan assembly 9, and the spray pipe 12 performs cooling and spraying on the flue gas;

[0055] S3: The cooled flue gas enters the desulfurization tower 1, and the circulation pump 1 22 and the calcium hydroxide solvent tank 23 are controlled to make the reaction between sulfur dioxide and calcium hydroxide solution;

[0056] S4: The reacted precipitation mixture is dehydrated through the dehydration component 26, and the sulfur dioxide after the precipitation is removed is rewashed into the return water tank 27 to realize the recycling of the calcium hydroxide solution;

[0057] S5: introducing the reacted flue gas into the defogging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com