Processing method of water-dependent permeable organic fertilizer

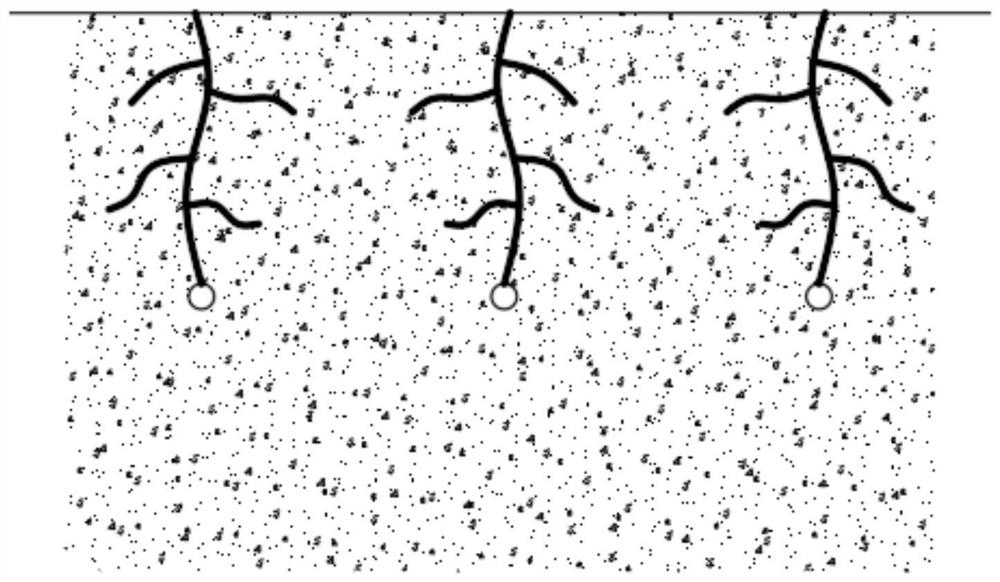

A processing method and technology of organic fertilizers, applied in the directions of organic fertilizers, nitrogen fertilizers, phosphate fertilizers, etc., can solve the problems of difficult diffusion distribution, decline of soil physical and chemical properties, difficulty in lateral diffusion and penetration, etc., and achieve the effect of expanding the scope of water absorption and expanding the scope of diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

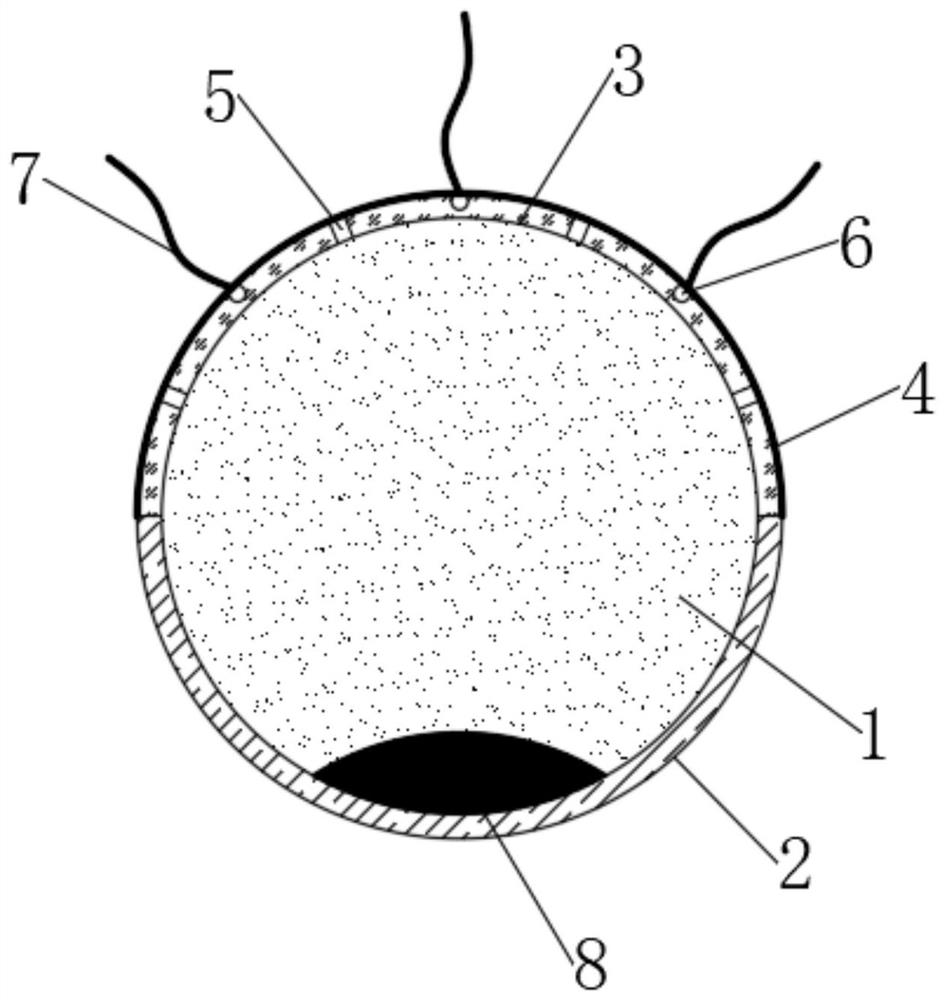

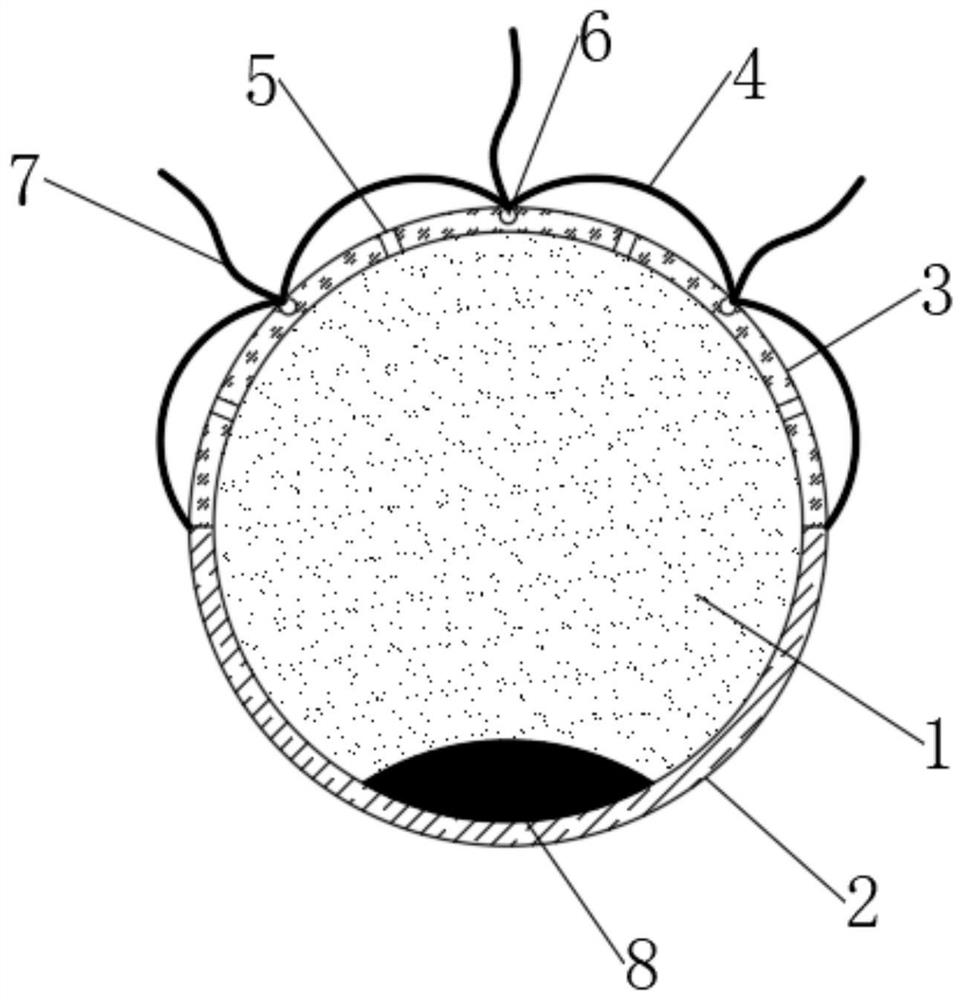

[0041] See figure 1 , A processing method of molecular permeability organic fertilizer, including the following steps:

[0042] S1, 30-40 parts of animal feces, 10-20 part of soybean meal, 20-30 straw powder and 5-10 servants were dried at 60-80 ° C, and then pulverized mixture, the preliminary mixture was obtained;

[0043] S2, a particulate ozage disc in the fermentation chamber is preserved, and the preliminary mixture is pushed on the oxygen dispensing plate, and then the 2-6 parts of the starch and 5-10 composite microbacterial agents are evenly put into oxygen fermentation 5- 7 days, where the fermentation temperature was 35-45 ° C to obtain a fermentation product;

[0044] S3, the fermentation product with 10-25 parts of urea, 6-15 parts of potassium dihydrogen, 25-35 humic acid, 3-5 parts of trace elements, 15-25 parts of Hessis and 15-25 pieces Uniformly mixed to obtain the final product;

[0045] S4, the final product is dried, and then the package is packaged to obtain...

Embodiment 2

[0057] Processing method of molecular permeability organic fertilizer, including the following steps:

[0058] S1, 30-40 parts of animal feces, 10-20 part of soybean meal, 20-30 straw powder and 5-10 servants were dried at 60-80 ° C, and then pulverized mixture, the preliminary mixture was obtained;

[0059] S2, a particulate ozage disc in the fermentation chamber is preserved, and the preliminary mixture is pushed on the oxygen dispensing plate, and then the 2-6 parts of the starch and 5-10 composite microbacterial agents are evenly put into oxygen fermentation 5- 7 days, where the fermentation temperature was 35-45 ° C to obtain a fermentation product;

[0060] S3, the fermentation product with 10-25 parts of urea, 6-15 parts of potassium dihydrogen, 25-35 humic acid, 3-5 parts of trace elements, 15-25 parts of Hessis and 15-25 pieces Uniformly mixed to obtain the final product;

[0061] S4, the final product is dried, and then the package is packaged to obtain a spherical produ...

Embodiment 3

[0064] Processing method of molecular permeability organic fertilizer, including the following steps:

[0065] S1, 30-40 parts of animal feces, 10-20 part of soybean meal, 20-30 straw powder and 5-10 servants were dried at 60-80 ° C, and then pulverized mixture, the preliminary mixture was obtained;

[0066] S2, a particulate ozage disc in the fermentation chamber is preserved, and the preliminary mixture is pushed on the oxygen dispensing plate, and then the 2-6 parts of the starch and 5-10 composite microbacterial agents are evenly put into oxygen fermentation 5- 7 days, where the fermentation temperature was 35-45 ° C to obtain a fermentation product;

[0067] S3, the fermentation product with 10-25 parts of urea, 6-15 parts of potassium dihydrogen, 25-35 humic acid, 3-5 parts of trace elements, 15-25 parts of Hessis and 15-25 pieces Uniformly mixed to obtain the final product;

[0068] S4, the final product is dried, and then the package is packaged to obtain a spherical produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com