Production process of fluorescent whitening agent OB-1

A fluorescent whitening agent, OB-1 technology, applied in the direction of organic chemistry, can solve the problems of low yield and pollute the environment, and achieve the effect of high yield and short synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

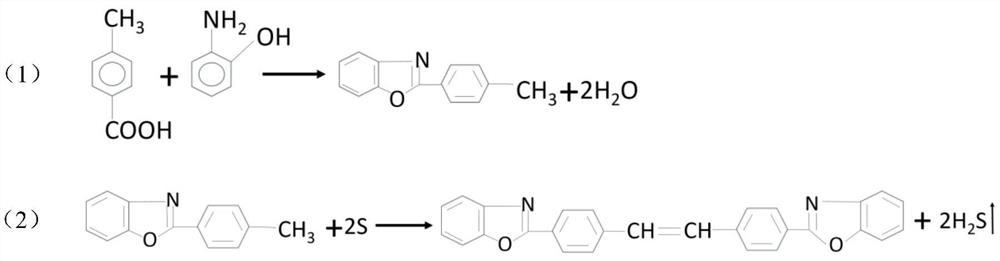

[0038] A kind of production technology of optical brightener OB-1, specifically comprises the following steps:

[0039] Step 1, condensation: p-toluic acid and o-aminophenol undergo a condensation reaction to generate 4-methylphenylbenzoxazole;

[0040] According to the molar ratio of o-aminophenol to p-toluic acid 1:1.43, and the mass ratio of o-aminophenol to solvent oil 1:3.5, first add 1500Kg of solvent oil into the beating kettle, start stirring, and then put p-toluene into the beating kettle 885Kg of formic acid and 500Kg of o-aminophenol are stirred evenly and then pumped into the condensation kettle through the dump pump; 99.99% nitrogen gas is introduced into the condensation kettle to prevent the material from being oxidized, and then the temperature of the material in the condensation kettle is raised to above 120°C to start condensation dehydration Reaction, reaction for 20 hours, the reaction temperature rises to 220°C, and the reaction is completed to obtain a 4-...

Embodiment 2

[0057] A kind of production technology of optical brightener OB-1, specifically comprises the following steps:

[0058] Step 1, condensation: p-toluic acid and o-aminophenol undergo a condensation reaction to generate 4-methylphenylbenzoxazole;

[0059] According to the molar ratio of o-aminophenol to p-toluic acid 1:1.23, and the mass ratio of o-aminophenol to solvent oil 1:2.5, first add 1250Kg of solvent oil into the beating kettle, start stirring, and then put p-toluene into the beating kettle 761Kg of formic acid and 500Kg of o-aminophenol are stirred evenly and pumped into the condensation kettle through the dump pump; 99.99% nitrogen gas is introduced into the condensation kettle to prevent the material from being oxidized, and then the temperature of the material in the condensation kettle is raised to above 110°C to start condensation dehydration Reaction, reaction for 22 hours, the reaction temperature rose to 210°C, and the reaction was completed to obtain a 4-methy...

Embodiment 3

[0076] A kind of production technology of optical brightener OB-1, specifically comprises the following steps:

[0077] Step 1, condensation: p-toluic acid and o-aminophenol undergo a condensation reaction to generate 4-methylphenylbenzoxazole;

[0078] According to the molar ratio of o-aminophenol to p-toluic acid 1:1.63, and the mass ratio of o-aminophenol to solvent oil 1:3, first add 1750Kg of solvent oil into the beating kettle, start stirring, and then put p-toluene into the beating kettle 1009Kg of formic acid and 500Kg of o-aminophenol are stirred evenly and pumped into the condensation kettle through the dump pump; 99.99% nitrogen gas is introduced into the condensation kettle to prevent the material from being oxidized, and then the temperature of the material in the condensation kettle is raised to above 130°C to start condensation dehydration Reaction, reaction for 18 hours, the reaction temperature rose to 230°C, and the reaction was completed to obtain a 4-methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com