Production process of wall-broken protein of blue-green algae

A production process and cyanobacteria technology, applied in the field of solid waste recycling, can solve the problems of air pollution and high energy consumption, and achieve the effect of realizing ecological circulation, reducing drying energy consumption, and highly unified environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

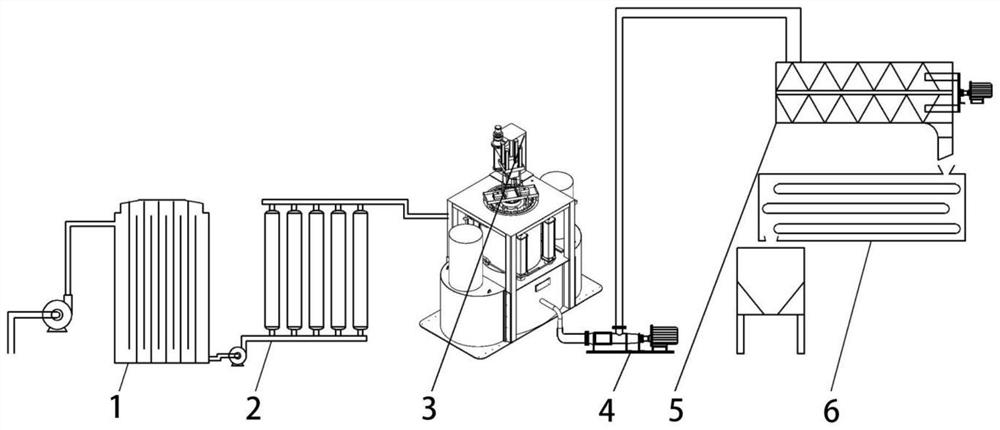

Image

Examples

Embodiment 1

[0028] 1. Pump cyanobacteria and algae water (with a solid content of about 0.4%) from the lake into the MF-1000 type non-pharmaceutical algae water separation device, filter through a 5 μm organic membrane, and separate from the free water outside the cyanobacteria cells to obtain a solid content of 6.5%. Spirulina algae mud;

[0029] 2. Send the algae mud into the steam explosion machine, feed 1.8MPa saturated water vapor and hold the pressure for 6 minutes, complete the steam explosion, and obtain the broken cyanobacteria liquid protein; the algae toxin content is 292μg·Kg -1 Remove to 2.74μg·Kg -1 , the algae toxin removal rate is 99.0%;

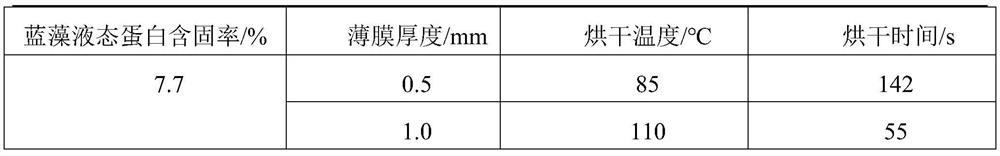

[0030] 3. Send the exploded cyanobacteria liquid protein (7.7% solid content) into a film dryer for drying, and dry at different temperatures for a certain period of time to obtain dried cyanobacteria flakes with a water content of 10% to 12%.

[0031] Table 1

[0032]

Embodiment 2

[0034] 1. Pump cyanobacteria and algae water (with a solid content of about 0.4%) from the lake into the MF-1000 type non-chemical algae water separation device, filter through a 15 μm organic membrane, and separate from the free water outside the cyanobacteria cells to obtain a solid content of 5%. Spirulina algae mud;

[0035] 2. Send the algae mud into the membrane concentrator for further separation and concentration, so that the solid content rate is further increased to 20.4%;

[0036] 3. Send the cyanobacteria algae mud obtained in the previous step into the steam explosion machine, feed 1.8MPa saturated water vapor and keep the pressure for 6 minutes, and then complete the steam explosion within 0.008 seconds, and obtain the cyanobacteria liquid protein after the wall is broken. Toxin content from 292μg·Kg -1 Remove to 2.74μg·Kg -1 , the algae toxin removal rate is 99.0%;

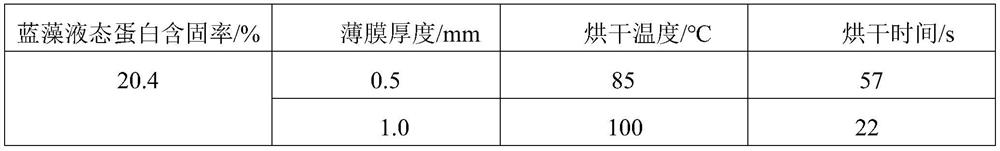

[0037] 4. Send the exploded cyanobacteria liquid protein into a film dryer for drying, and dr...

Embodiment 3

[0042] 1. Pump cyanobacteria water (with a solid content of about 0.4%) from the lake into the MF-1000 type non-pharmaceutical algae water separation device, filter it through a 35 μm organic membrane, and get rid of the free water outside the cyanobacteria cells to obtain a solid content of 3.5%. Spirulina algae mud;

[0043] 2. Put the algae mud into the steam explosion machine, inject 1.4MPa saturated water vapor and hold the pressure for 4 minutes, complete the steam explosion, and obtain the cyanobacteria liquid protein after the wall is broken; the algae toxin content is 292μg·Kg -1 Remove to 62μg·Kg -1 , the removal rate of algae toxin is 78.8%;

[0044] 3. Send the exploded cyanobacteria liquid protein (4.4% solid content) into a film dryer for drying, and dry at different temperatures for a certain period of time to obtain dried cyanobacteria flakes with a water content of 10% to 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com