Conductive carbon substrate loaded graphene aerogel composite electrode and preparation method thereof

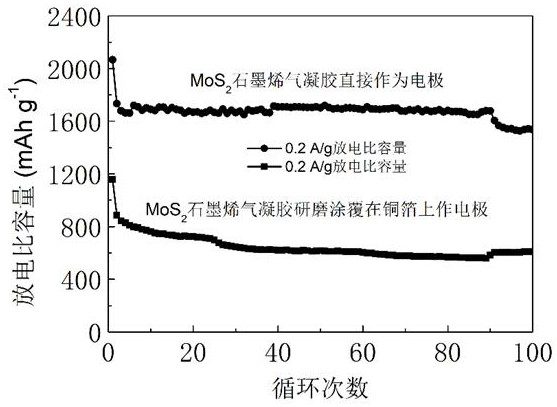

A graphene airgel and substrate-loaded technology, applied in the field of electrodes, can solve the problems of inhibiting the electrochemical performance of active materials, destroying the 3D continuous conductive network, and reducing the performance of electrodes, so as to achieve less preparation process and improve electrochemical stability , the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

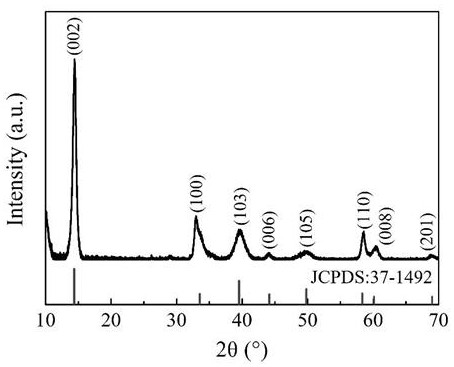

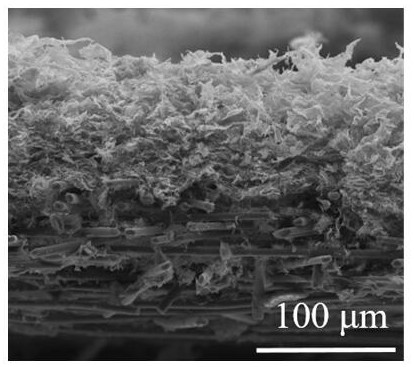

[0055] Preparation with Molybdenum Salt: Carbon Fiber Paper Supported MoS 2 The preparation method of graphene airgel composite electrode, concrete steps are as follows:

[0056] Step 1. At room temperature, 75 mg (NH 4 ) 2 MoS 4 (Ammonium tetrathiomolybdate) was added to 10 mL of graphene oxide dispersion with a concentration of 3 mg / mL (water / ethanol volume ratio 3:1, 10 mL in total), and then the mixed solution was ultrasonically oscillated to obtain a uniform Precursor solution A;

[0057] Step 2. Cut 9×3.5cm carbon fiber paper with a microtome, ultrasonically treat it with ethanol and deionized water for 10 minutes, and then dry it at 60°C for 30 minutes;

[0058] Use a pipette gun to pipette a certain volume of precursor solution A and drop it on carbon fiber paper, then put the composite into liquid nitrogen for rapid cooling, and then freeze-dry it in a freeze dryer to obtain a carbon fiber paper-loaded precursor Aerogel;

[0059] Step 3. Put the carbon fiber pap...

Embodiment 2

[0068] Preparation with Iron Salt: Carbon Cloth Supported Fe 2 o 3 The preparation method of graphene airgel composite electrode, concrete steps are as follows:

[0069] Step 1, under room temperature conditions, 120mg FeCl 3 (Ferric chloride) was added to 6mL graphene oxide dispersion solution with a concentration of 5mg / mL (water / acetone volume ratio 1:2, 6mL in total), and then the mixed solution was ultrasonically oscillated to obtain a uniform precursor solution A;

[0070] Step 2. Use a microtome to cut the carbon cloth into discs with a diameter of 14mm, ultrasonically treat with ethanol and deionized water for 10 minutes, and then dry at 60°C for 30 minutes;

[0071] Use a pipette gun to pipette a certain volume of precursor solution A and drop it on the carbon cloth, then put the composite into liquid nitrogen for rapid cooling, and then freeze-dry it in a freeze dryer to obtain a carbon cloth-loaded precursor Aerogel;

[0072] Step 3. Put the carbon cloth-loaded...

Embodiment 3

[0079] Preparation with Molybdenum Salt: Carbon Fiber Paper Supported MoS 2 The preparation method of graphene airgel composite electrode, concrete steps are as follows:

[0080] Step 1, under room temperature conditions, 180mg (NH 4 ) 6 Mo 7 o 24 ∙4H 2 O (ammonium heptamolybdate) and 22 mg of thiourea were added to 15 mL of graphene oxide dispersion with a concentration of 2 mg / mL (volume ratio of water / ethanol was 1:1, 15 mL in total), and then the mixed solution was ultrasonically oscillated. Obtain a uniform precursor solution A;

[0081] Step 2. Use a microtome to cut into discs of carbon fiber paper with a diameter of 14mm, ultrasonically treat with ethanol and deionized water for 10 minutes, and then dry at 60°C for 30 minutes;

[0082] Use a pipette gun to pipette a certain volume of precursor solution A and drop it on carbon fiber paper, then put the composite into liquid nitrogen for rapid cooling, and then freeze-dry it in a freeze dryer to obtain a carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com