Preparation method of pearl powder sunscreen cream

A pearl powder and sunscreen technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of pearl powder waste, low utilization rate of pearl powder, and increased cost of pearl powder sunscreen, and achieve the utilization rate The effect of improving, improving the preparation efficiency and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

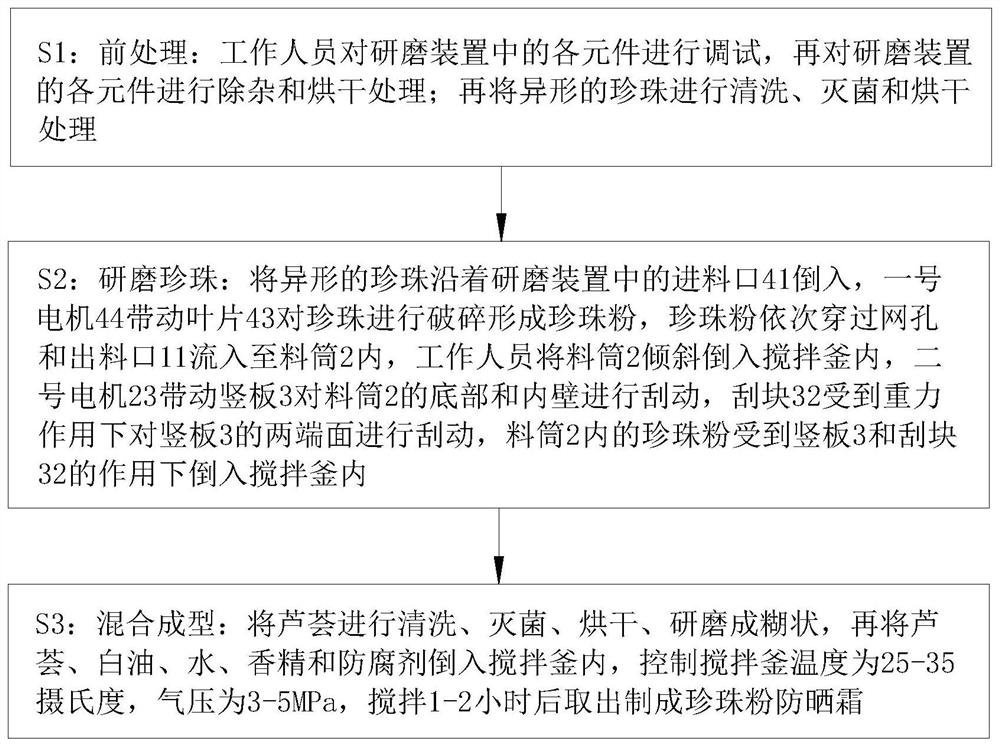

[0037] like Figure 1 to Figure 8 Shown, the preparation method of a kind of pearl powder sunscreen of the present invention, comprises the following steps:

[0038] S1: Pre-treatment: The staff debugs each component in the grinding device, and then removes impurities and dries the components of the grinding device; then cleans, sterilizes and dries the special-shaped pearls; The device is debugged to ensure the stability of the grinding device in motion; by removing impurities from the grinding device, it is ensured that the pearl powder will not be polluted, and by drying the grinding device to prevent the pearl powder from sticking to the grinding device on the internal components, resulting in waste of pearl powder;

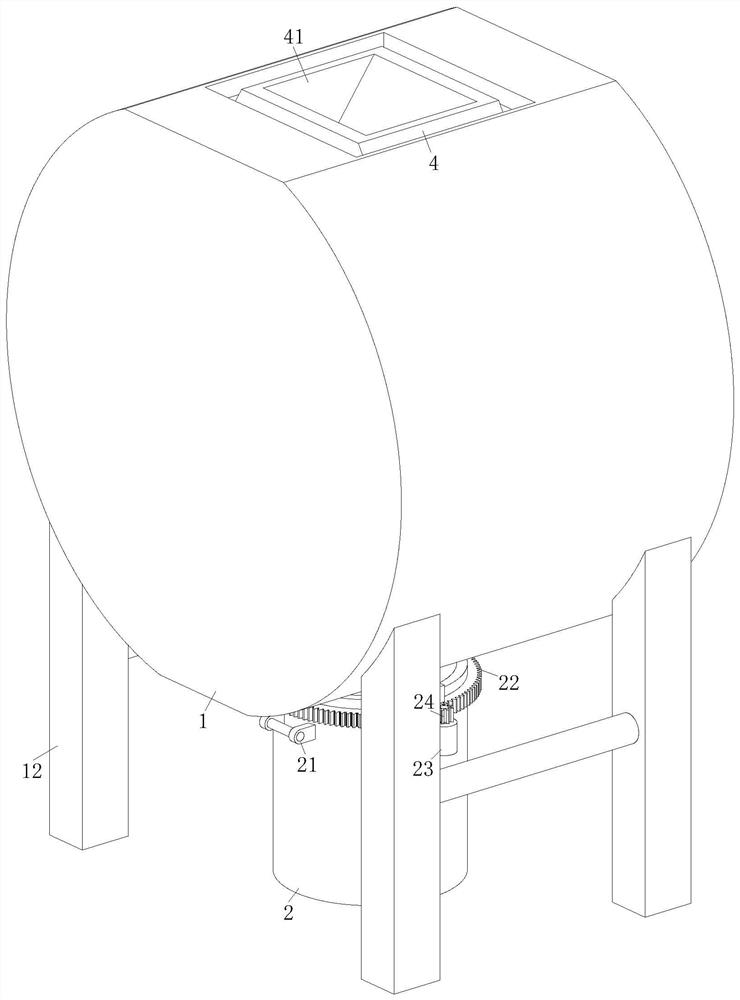

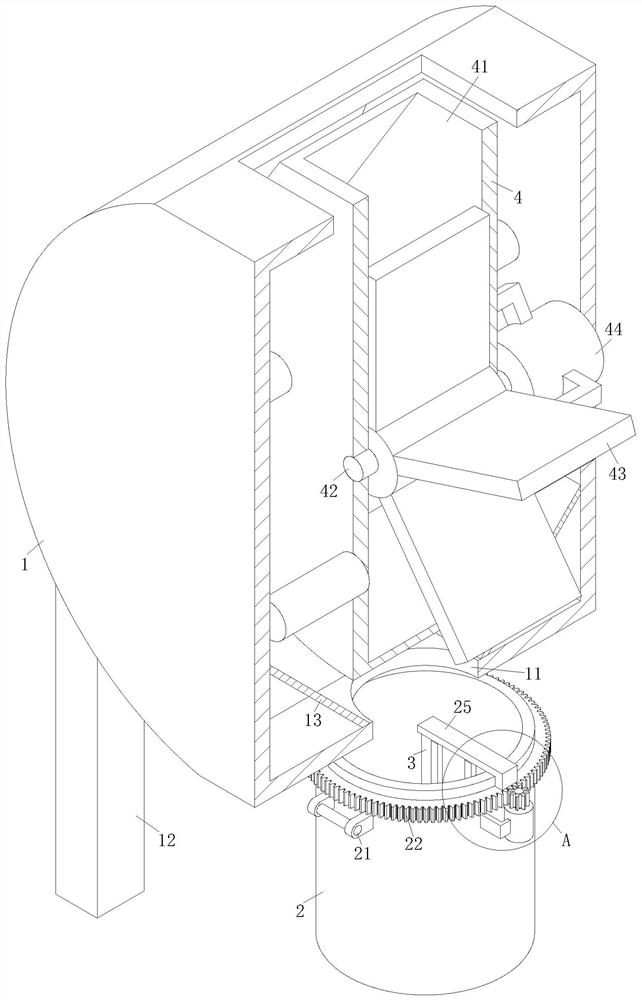

[0039] S2: Grinding pearls: pour the special-shaped pearls along the feeding port 41 in the grinding device, and the No. 1 motor 44 drives the blade 43 to crush the pearls to form pearl powder, which flows through the mesh and the discharge port 11 in turn ...

Embodiment approach

[0045] As an embodiment of the present invention, a paddle 5 is fixedly connected to the other side of the vertical board 3; the paddle 5 is evenly distributed on the other side of the vertical board 3; the paddle 5 is Y-shaped; When in use, during the process of collecting pearl powder in the barrel 2, due to the high air humidity, the pearl powder falls into the barrel 2, and it is easy to agglomerate in the barrel 2. Stirring can only push the pearl powder in the barrel 2, so that the vertical plate 3 has limitations; therefore, when the pearl powder at the discharge port 11 falls into the barrel 2 in the present invention, the motor drives the vertical plate 3 to move, and the vertical plate 3 moves. The plate 3 will drive the fixed stirring rod 5 to move, so that the pearl powder in the barrel 2 will not agglomerate under the agitation of the stirring rod 5, thereby improving the quality of the pearl powder and making the preparation of the pearl powder sunscreen effect i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com