Thermoplastic resin composition and application thereof

A thermoplastic resin and composition technology, applied in the direction of synthetic resin layered products, flame-retardant fibers, layered products, etc., can solve the problems of poor flame-retardant effect, impact on basic performance of thermoplastic resin, and decline in mechanical properties, and achieve improved High temperature stability and flame retardant performance, the effect of reducing the effect of high temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

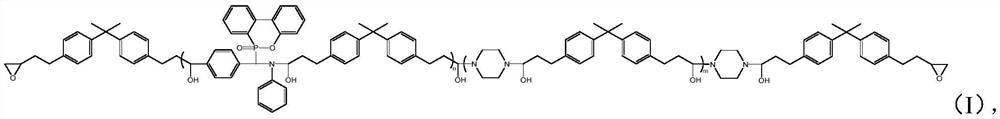

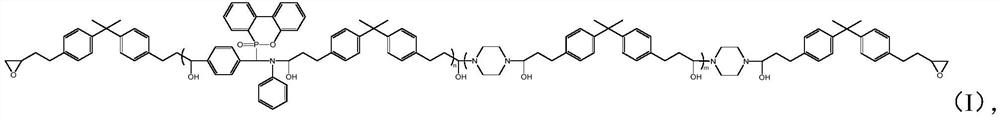

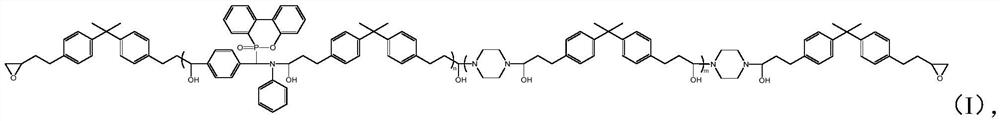

Image

Examples

Embodiment 1

[0046] This embodiment provides a kind of thermoplastic resin composite material, the preparation method of this composite material comprises the following steps:

[0047] (1) Preparation of modified carbon fiber

[0048] The carbon fiber is impregnated in the surface modifier solution (the number-average molecular weight of the thermoplastic phosphorus-containing epoxy resin is about 10000, and the phosphorus content is 15wt%) in the concentration of 1wt%, and the wire speed is 2cm / s, and then enters the oven to dry Dry at a temperature of 150°C for 5 minutes, and finally wind up to obtain modified carbon fibers.

[0049] (2) Preparation of thermoplastic resin film

[0050] The nylon resin of 100g, the phosphorus-nitrogen compound of 30g (melamine phosphate and melamine cyanurate each 15g), the hydrotalcite of 10g, the zinc borate of 10g, the anti-oxidant of 0.5g are added in the extruder and mix uniformly, and Feed into the mold to obtain a uniform thermoplastic resin film...

Embodiment 2

[0054] This embodiment provides a kind of thermoplastic resin composite material, the preparation method of this composite material comprises the following steps:

[0055] (1) Preparation of modified carbon fiber

[0056] The carbon fiber is impregnated in the surface modifier solution (the number-average molecular weight of the thermoplastic phosphorus-containing epoxy resin is about 10000, and the phosphorus content is 15wt%) in the concentration of 1wt%, and the wire speed is 2cm / s, and then enters the oven to dry Dry at a temperature of 150°C for 5 minutes, and finally wind up to obtain modified carbon fibers.

[0057] (2) Preparation of thermoplastic resin film

[0058] 100g of nylon resin, 30g of melamine cyanurate, 10g of hydrotalcite, 10g of zinc borate, and 0.5g of antioxidant were added to the extruder and mixed evenly, and fed into a mold to obtain a uniform thermoplastic resin film.

[0059] (3) Preparation of composite materials

[0060] The modified carbon fib...

Embodiment 3

[0062] This embodiment provides a kind of thermoplastic resin composite material, the preparation method of this composite material comprises the following steps:

[0063] (1) Preparation of modified carbon fiber

[0064] The carbon fiber is impregnated in the surface modifier solution (the number-average molecular weight of the thermoplastic phosphorus-containing epoxy resin is about 10000, and the phosphorus content is 15wt%) in the concentration of 1wt%, and the wire speed is 2cm / s, and then enters the oven to dry Dry at a temperature of 150°C for 5 minutes, and finally wind up to obtain modified carbon fibers.

[0065] (2) Preparation of thermoplastic resin film

[0066] The nylon resin of 100g, the phosphorus-nitrogen compound of 20g (melamine phosphate and melamine cyanurate each 10g), the hydrotalcite of 10g, the zinc borate of 5g, the anti-oxidant of 0.5g are added in the extruder and mix uniformly, and Feed into the mold to obtain a uniform thermoplastic resin film....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com