Dewatering water advanced treatment softening system and process

An advanced treatment and dehydration technology, which is applied in the fields of water softening, water/sewage treatment, mining wastewater treatment, etc., can solve the problems of large area occupied by the lime treatment system, increased sludge disposal costs, and difficult operation. Achieve the effects of small footprint, high degree of automation, and small maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

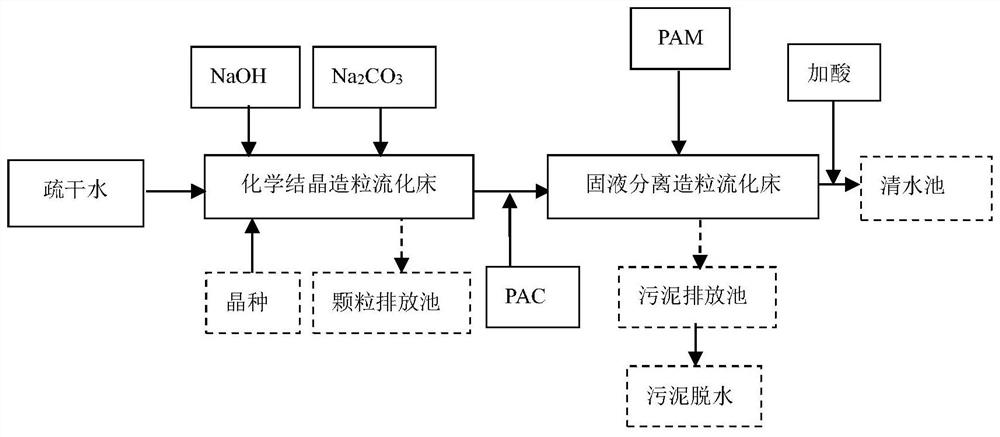

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

[0026] refer to figure 1 , a dewatering water advanced treatment softening process, the process flow is as follows: Mine dewatering water → crystallization granulation → solid-liquid separation and filtration → acid neutralization → clear water; crystal seeds, alkaline agents and Mine drainage water reaction, adding coagulant and coagulant during solid-liquid separation, acid neutralization after solid-liquid separation and filtration to obtain clear water;

[0027] Specifically include the following steps:

[0028] Mine dewatering water enters the chemical crystallization granulation fluidized bed through the delivery pump;

[0029] Add sodium hydroxide, sodium carbonate and crystal seeds to the chemical crystallization granulation fluidized bed to react with raw water;

[0030] The drained water is softened by chemical crystallization and granulation, and then ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com